While new supercritical power plants are coming up, a large number of old power plants need to be upgraded to avoid frequent shut down for maintenance. Maintenance and instrumentation engineers are facing several challenges to maintain a high uptime.

Understanding machine health and planning actions in advance can increase plant uptime to 95%. Monitoring of critical machines is key to increasing efficiency and reliability and prevent frequent failures. Real time vibration monitoring helps prevent frequent failures.

What Causes Vibrations?

There are several reasons for vibration in machines. They can be due to:

• Unbalance of shaft

• Bearing problem

• Cracking of the rings

• Fluid coupling problem

• Shaft misalignment

• Oil whirl and other dynamic instabilities

These problems can gradually become very severe and result in unplanned shutdowns. To avoid this, shutdowns are planned. Time Based Maintenance System (TBM) is called preventive maintenance. One can extend the life of the machines by monitoring these online in a cost effective way. Vibration monitoring and analysis is the easiest way to keep machines healthy and efficient in the long run and increase the overall efficiency of the plant. It reduces the overall operating cost as well as the down time period. Vibration sensors are used to predict faults in a running machine without dismantling it and give a clear indication of the severity by showing the amplitude of vibration.

It is essential that power plants invest in robust vibration monitoring systems that offer the latest technology to maintain plant safety and asset protection, with reduced downtime and avoiding untimely shutdowns of equipment like pumps, motors, fans, compressors, and turbine supervisory systems. Online vibration monitoring systems are the need of hour and offer the user indirect payback in the form of protection of critical machinery and reduced maintenance costs.

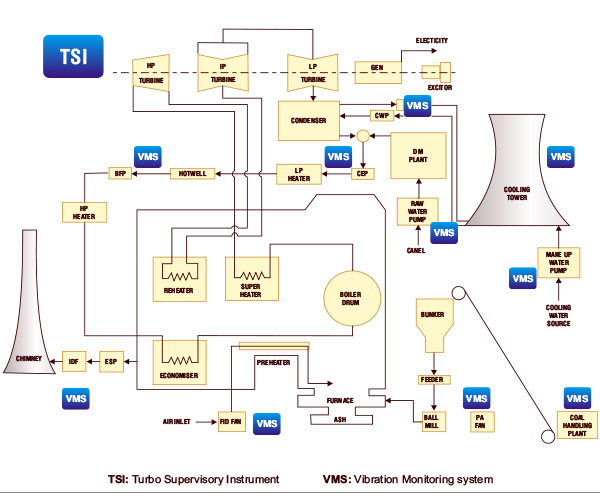

The figure below indicates all critical machinery where vibration monitoring is recommended.

Vibration monitoring is governed by the global standard API 670 IVth Edition – Machinery Protection System. For plant maintenance, it is useful to have a uniform system such as API 670 compliant vibration sensors, rack based monitoring systems with required relay outputs, 4-20 mA outputs, DCS Interface and raw buffer signal output for further integration. Under API 670 all suppliers are brought onto a single platform and it is possible to replace sensors and monitors in existing systems with those of other suppliers. It is also a good practice to follow API 670 design standard for turbines and other applicable BOP machines in power plants to avoid issues later on.

Visit Vibration Monitoring Solutions to read more about Forbes Marshall’s solutions for vibration monitoring.