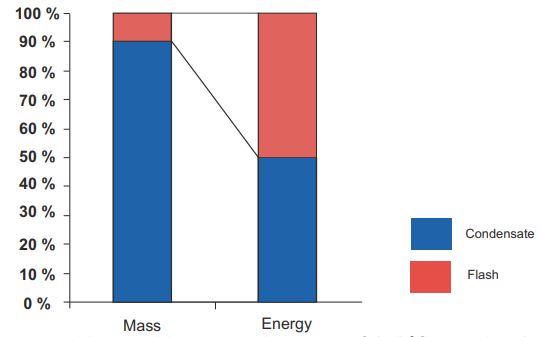

Recover flash steam to utilise the energy present in high pressure condensate and thus reduce fuel bills. In a mixture of condensate and flash, although flash steam is only about 10% by mass it holds 50% of the energy content of condensate.

When condensate is discharged via steam traps, from high to low pressure, some of the condensate evaporates into flash steam.

The amount of heat present in condensate determines the quantity of flash steam formed. Typically, the flash steam formed, is about 10%-15% of the condensate.

E.g. : 1 kg of condensate at 4 bar g with a saturation temp of 152°C contains 152 kcal of heat. The condensate is discharged to the atmosphere via a steam trap. At atmospheric pressure, water is at a temperature of 99°C with 99 kcal of heat. This means there is now an excess heat of 53°C or 53kcal.

As per laws of thermodynamics, energy can neither be created nor be destroyed. This excess heat is used in boiling a portion of condensate into flash steam, thereby maintaining the energy balance.

1 kg of steam at atmospheric pressure has a total energy content of 638 kcal. So 53 kcal will boil 120 gms of the 1 kg of condensate into flash steam.

As seen, the energy converted to flash steam (53kcal) is more than half the energy in 1 kg of condensate (99kcal) but is only 12% of mass of condensate. Thus it is worthwhile to recover both condensate and flash steam.