Partial or no condensate return will result in higher fuel and water consumption. Ensure maximum condensate is returned to the feedwater system.

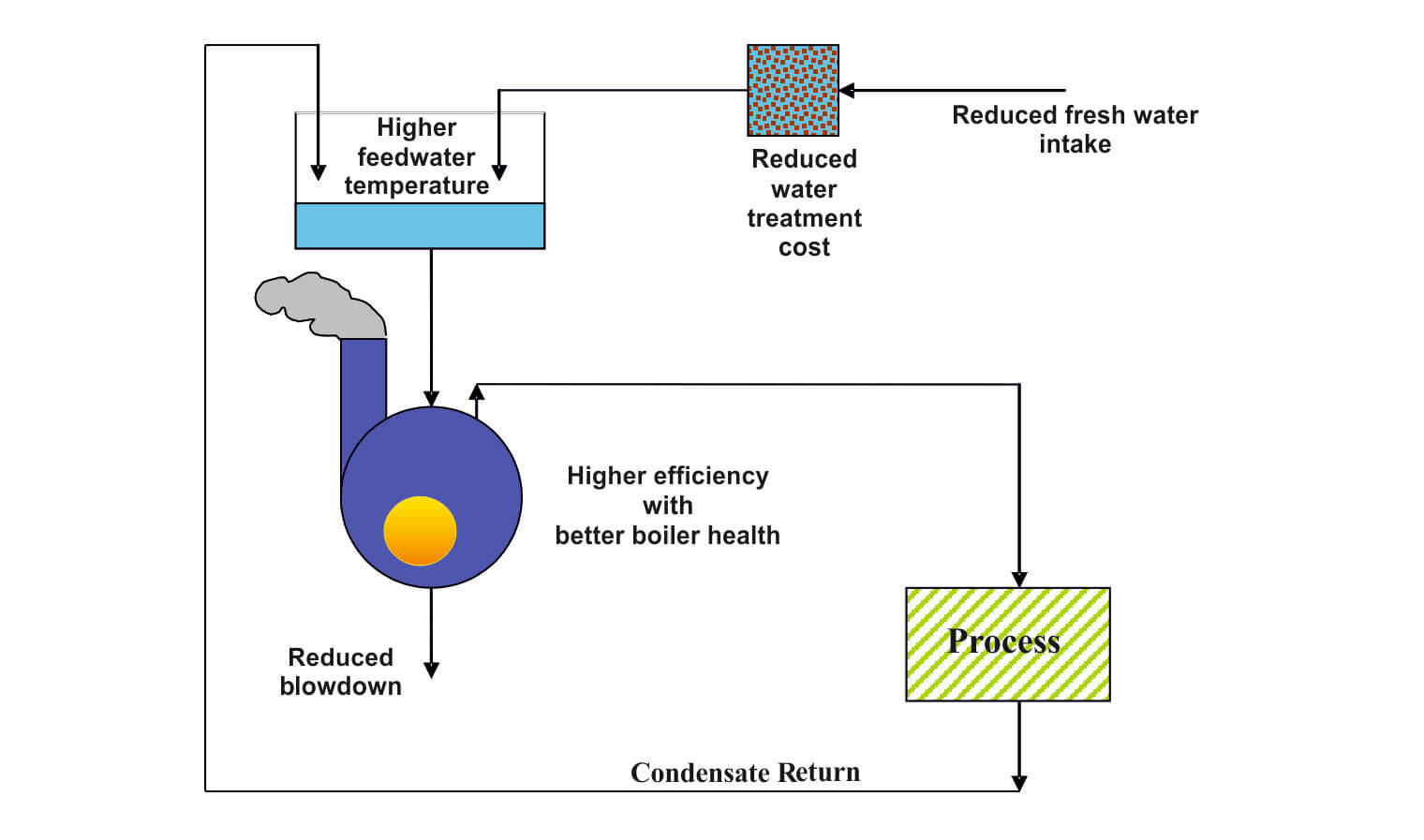

Recovering condensate has multiple benefits. While condensate holds almost 20% of the energy in steam, the first benefit of returning condensate is that it improves the feedwater temperature and thus lowers fuel bill.

The second benefit is that returning condensate to the feed water tank reduces the amount of make up water required. As condensate is formed by condensing steam it does not contain the impurities present in makeup water. The condensate returned does not need to undergo water treatment, saving treatment cost and this is the third benefit.

The fourth benefit is that condensate, being free of impurity and chemical additives, does not add to the TDS levels of water in the boiler. This reduces the requirement of blowdown thereby curtailing blowdown losses.

Thus, returning condensate holds multiple benefits for the plant.

Illustrations: Benefits of Condensate Return