Water droplets (moisture) traveling at steam velocities erode valve seats and fittings, leading to leaks. Install moisture separators to maintain dryness of steam.

Steam containing moisture / water droplets is called wet steam. It reduces plant performance and product quality while causing damage to equipment. When water droplets travel at high steam velocity, they erode the valve seat and fittings causing a condition known as wire drawing. They also increase the amount of corrosion.

Most of the water droplets can be removed through proper drainage and effective trapping. The droplets suspended in steam can be removed by installing moisture separators in the line.

As a thumb rule, when the velocities in the pipework are within reasonable limits, separators will be the same as the line size.

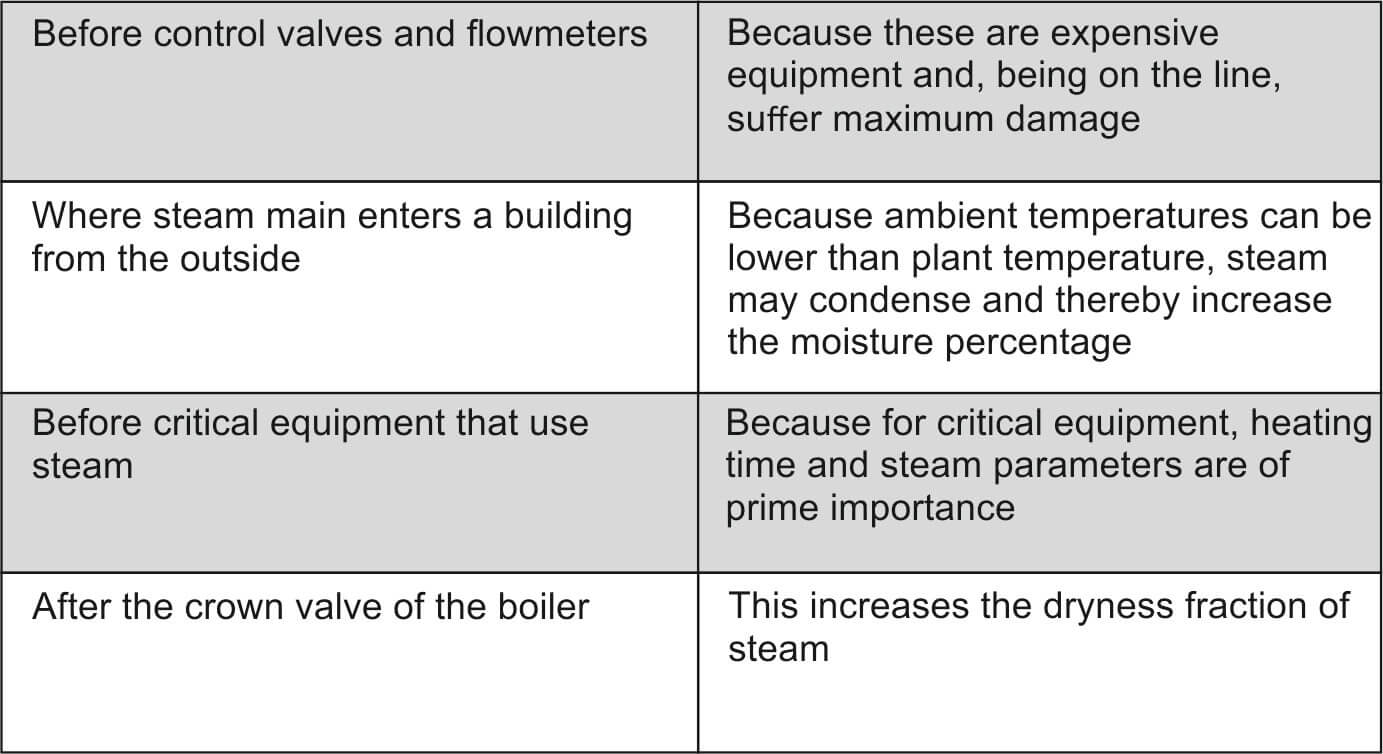

Recommended locations for moisture separators

* Moisture separators are especially effective and a must for coil type (NIBR) boiler which by design have a dryness fraction of 80% against 98% for shell type boilers.