Saturated steam has a higher heat transfer coefficient than super

heated steam. Use saturated steam for indirect heat transfer applications.

Latent heat of evaporation forms most of the energy content of steam. For

indirect heating applications in a process, it is this latent heat of evaporation in

steam that is actually utilised. The condensate which leaves the plant

equipment contains a portion of heat termed “sensible heat”.

In case of super heated steam, steam has to first cool to saturation

temperature before it can condense to release its latent heat. The amount of

heat given up by superheated steam while reaching saturation temperature is

relatively small in comparison to the latent heat of evaporation.

Thus, as long as steam is super heated it has a lower heat transfer co-efficient

as maximum heat transfer occurs when saturated steam transfers its latent

heat.

Illustration :

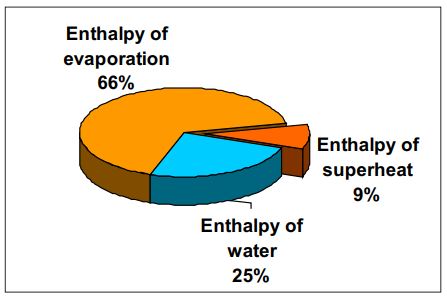

Heat energy contained in superheated steam is in the form of enthalpy of

water, latent heat / evaporation and superheat. The bulk of this energy is

enthalpy of latent heat / evaporation while the enthalpy of superheat forms the

smallest in proportion.

Consider superheated steam at 10 bar

g and 300 °C, then:

Enthalpy of water = 181 kcal/kg

Enthalpy of evaporation = 481.9 kcal/kg

Enthalpy of superheat = 65.7 kcal/kg

Superheated steam requires a larger

heat exchange area which, if not

provided, leads to reduced heat

exchange.