Condensate present in the steam system hampers heat transfer.Steam traps drain condensate and trap system,ensuring high heat transfer rates and hence fuel savings.

As steam travels from the boiler it begins to lose its heat and condenses into

water. This hot water formed, known as condensate, does not transmit heat

effectively and hence needs to be removed from the steam system.

A steam trap is used to effectively remove condensate from the steam piping /

equipment preventing condensate accumulation in the heating equipment

while simultaneously preventing steam from escaping from the system. This

delivers higher heat transfer rates and thus less steam consumption, resulting

in fuel savings.

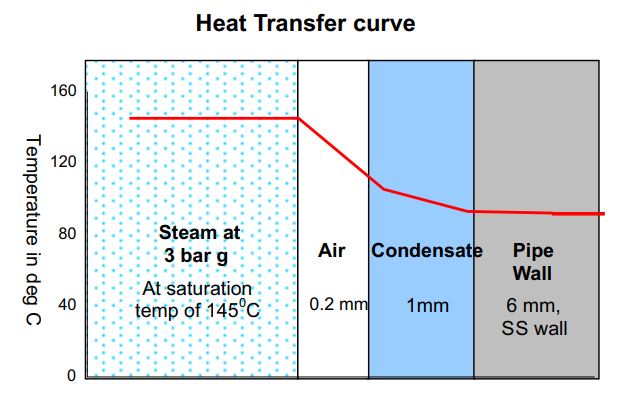

Illustration:

The graph below represents the temperature gradient across a steam pipe carrying steam at 3 bar (g). In this case 12.5°C is lost due to a 1 mm

condensate film.

Effective evacuation of condensate minimises this temperature drop leading to

effective heat transfer and reduced fuel consumption.