How does fuel quality impact boiler efficiency?

Are yesterday’s boiler settings still fit for today’s fuel? Boiler efficiency doesn’t just depend on the boiler, it depends heavily on the quality of fuel. In real-world conditions, fuel quality is rarely consistent. Whether it’s coal, wood, or biomass, solid fuels can vary significantly in quality and these variations quietly reduce boiler performance.

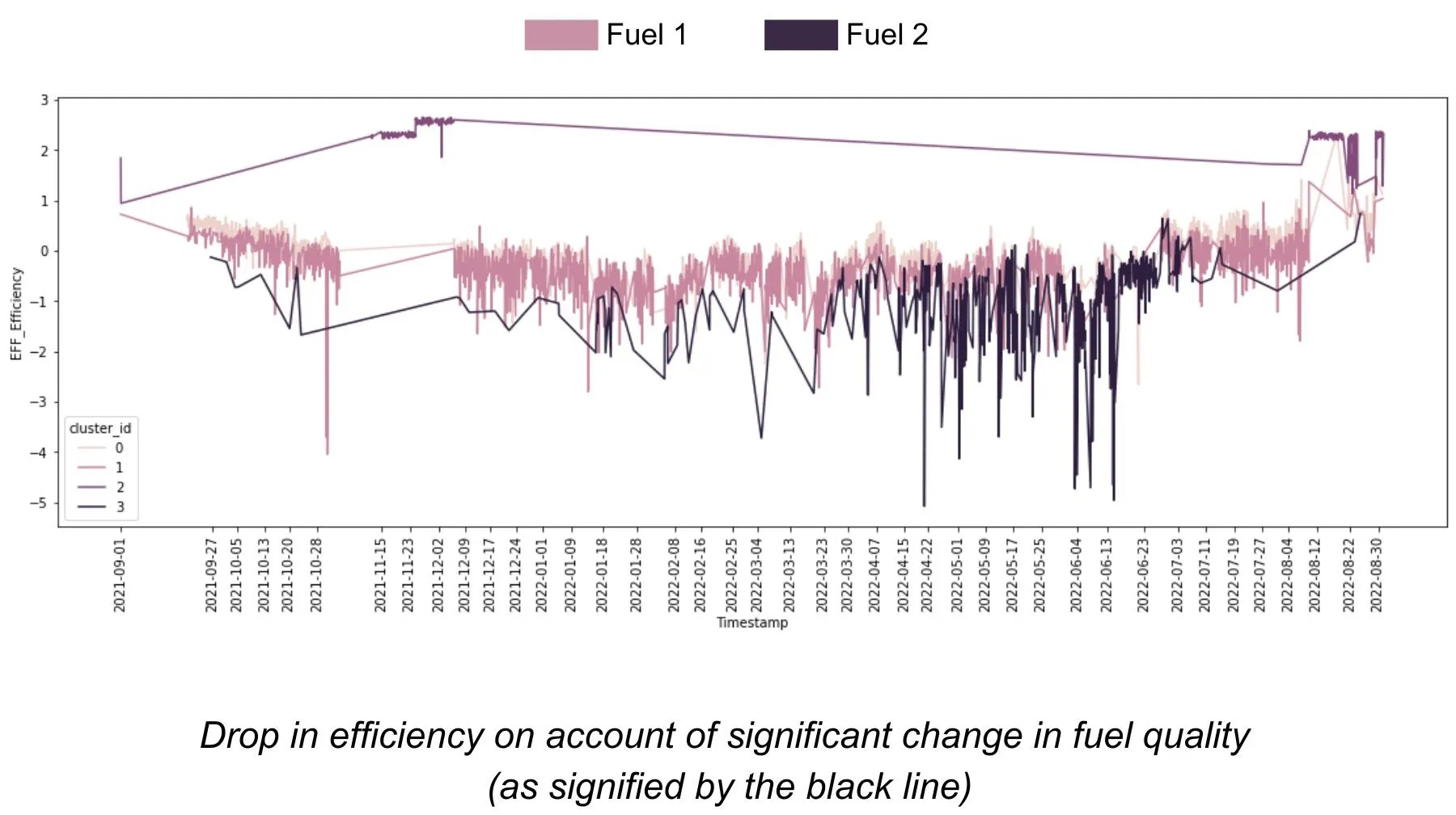

Even a small difference in gross calorific value (GCV) between batches can cause 2–3% higher fuel consumption, if combustion settings remain unchanged. For biomass, the variation is even more unpredictable across seasons or even batches. The ash content of solid fuels can differ widely affecting whether the fuel burns completely and how much residue is left behind.

Generally, boilers are operated on the same combustion settings regardless of these factors. As a result, they burn more fuel to generate the same amount of steam. This slowly increases operational cost, which goes unnoticed.

Here’s where EverSense for Boiler Efficiency, a Forbes Marshall Digital solution makes a real, sustainable impact.

By continuously monitoring combustion parameters and boiler performance, EverSense for Boiler Efficiency can detect minor drops in efficiency linked to fuel variation. This, combined with decades of expertise, enables our team to provide tailored recommendations on how to adjust air supply, burner settings, and firing conditions to match the current fuel quality – maintaining your boiler efficiency.