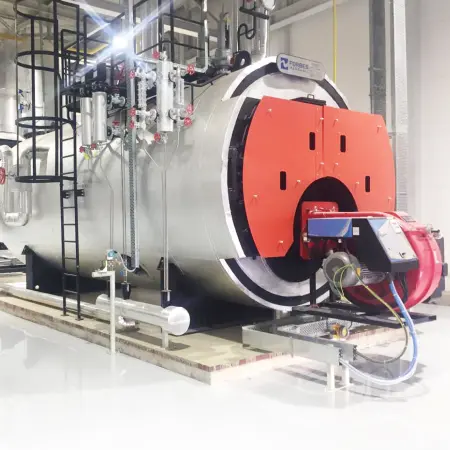

Edible oil production from seed/fruit involves multiple stages, from preparation and extraction to refining and packaging. Each stage presents challenges in energy efficiency, product quality, and cost control, all while ensuring sustainable operations.

Plants typically grapple with issues such as high steam consumption, oil and DOC quality variations, higher solvent loss, and frequent heat exchanger failures. These issues not only drive up operational costs but also disrupt process efficiency, thereby impacting both yield and profitability.

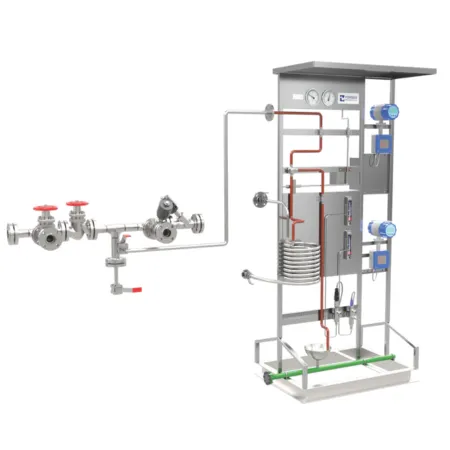

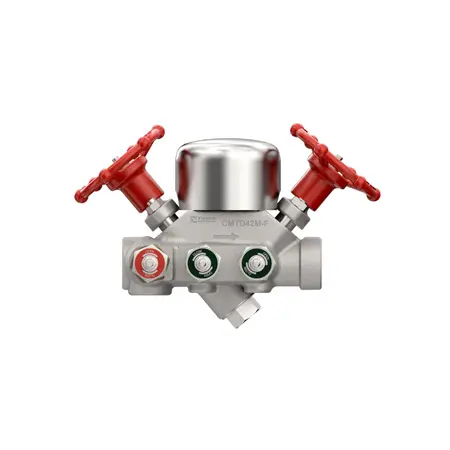

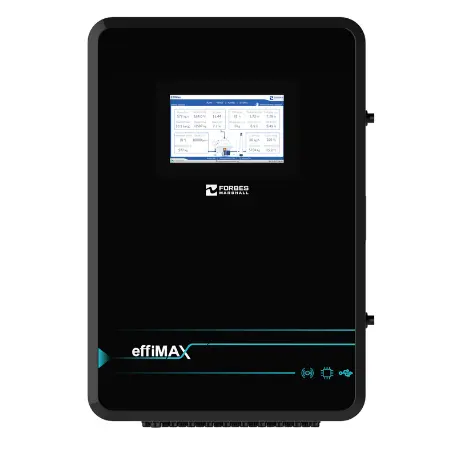

Forbes Marshall offers a range of innovative solutions to tackle these challenges. With advanced steam management systems, heat recovery solutions, and process automation, we help edible oil plants optimize energy use, enhance extraction and refining efficiency, and improve overall sustainability.

Let us help you

Explore our solutions for the Edible Oil and Fats Industry