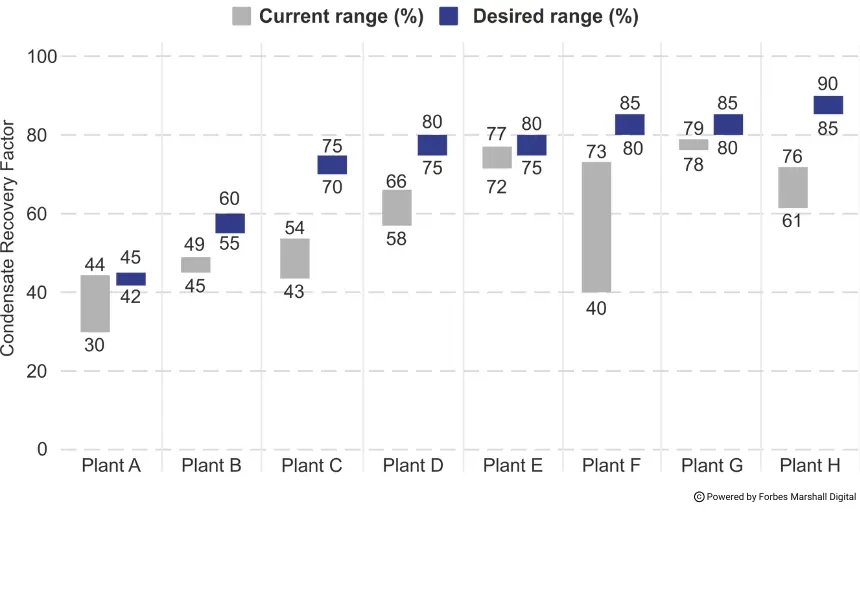

On average, plant condensate recovery can be improved by 10-15% and sustained through our solution.

In today’s dynamic and competitive landscape, where energy costs continue to rise, maintaining an efficient steam system is imperative. A drop in CRF leads to incremental fuel and fresh water consumption in the boiler and a higher effluent load.

CRF variation causes include:

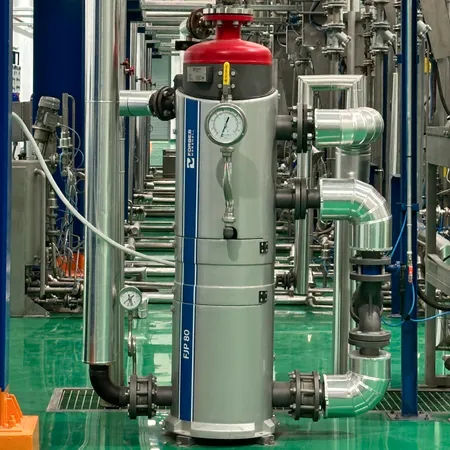

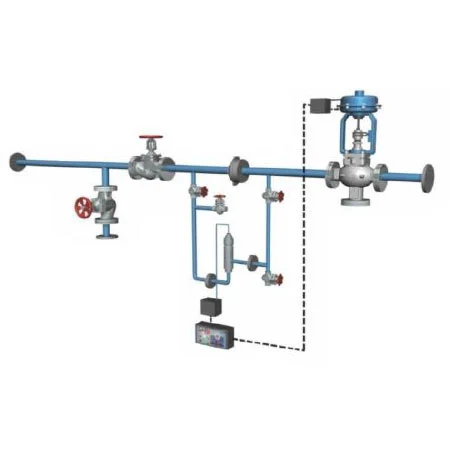

- Uptime or leakages of mainline, process traps or the condensate pump

- Unnecessary steam loss through a trap bypass valve

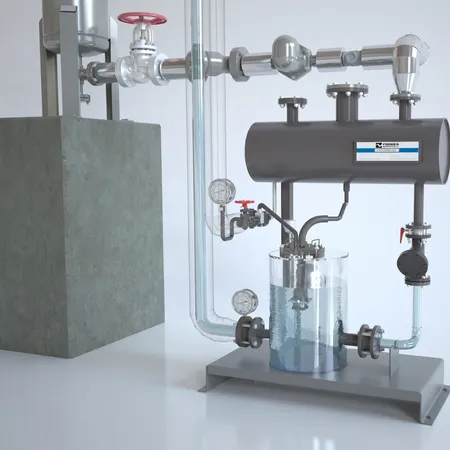

- Flash vented, condensate drained

- Feed water tank management

- Direct steam consumption

Key parameters we monitor

Condensate recovery

Feed water temperature

Steam flow

Condensate from various pumps

Make up water flow

We provide actionable insights

Delivering Benefits

Our

footprint

across services

footprint

across services

500

Plants

1200

Assets

7500

Parameters