Can better visibility into water management systems make industries more efficient?

Across industries, water plays a critical role, not just as a resource, but as a key enabler of productivity, energy efficiency, and sustainability. Yet, in most manufacturing facilities, the water treatment process often goes neglected. Leaks, pH drifts, and inefficiencies remain undetected until they eventually lead to a drop in performance or an unplanned breakdown. Traditional water management focuses on “how to use less water.” But in today’s competitive industrial landscape, the real question is: “How can better visibility into water management systems help us improve energy efficiency, production reliability, and operational sustainability?”

Why Traditional Monitoring Falls Short

Manual monitoring methods, routine audits, and one-time reports often miss early indicators of water loss, equipment fouling, and process inefficiency. Problems surface only after productivity drops or compliance alarms are triggered, by which point, significant energy, water, and chemical losses have already occurred.

How Digital Monitoring Bridges the Gap

Let’s go through a specific digital service to explain the benefits of digital monitoring:

EverSense for WaterMAP, a Forbes Marshall Digital service, digitally connects all key water-handling systems, right from cooling towers and boilers to effluent treatment plants (ETPs), reverse osmosis (RO) systems, and demineralisation (DM) units. By doing so, the service turns the water network into a continuously monitored, digitally connected ecosystem that offers actionable insights instead of raw data. Using smart sensors and cloud analytics, the Forbes Marshall domain experts correlate water, energy, and production data in real time.

This enables early detection of anomalies like:

Cooling tower blowdown mismatches

Valve leakages or bypasses

pH drift or contamination events

Heat exchanger fouling

Excess chemical dosing or filter backwash losses

The 5Rs Framework

This framework highlights how one can quantify and improve the full lifecycle of industrial water:

- Reduce: Early detection of leakages, fouling, and wastage can save 6-8% non-revenue water.

- Reuse: Real-time digital monitoring ensures water quality and consistency, enabling 60-75% water reuse rates.

- Recycle: Monitors process recovery efficiency, helping achieve up to 80% water recovery.

- Tracks waste heat recovery and thermal efficiency improvements adding up to 150 MWh/year in value.

- Recharge: Connects recycled water with groundwater replenishment, enabling up to 128 million litres of annual water table recharge.

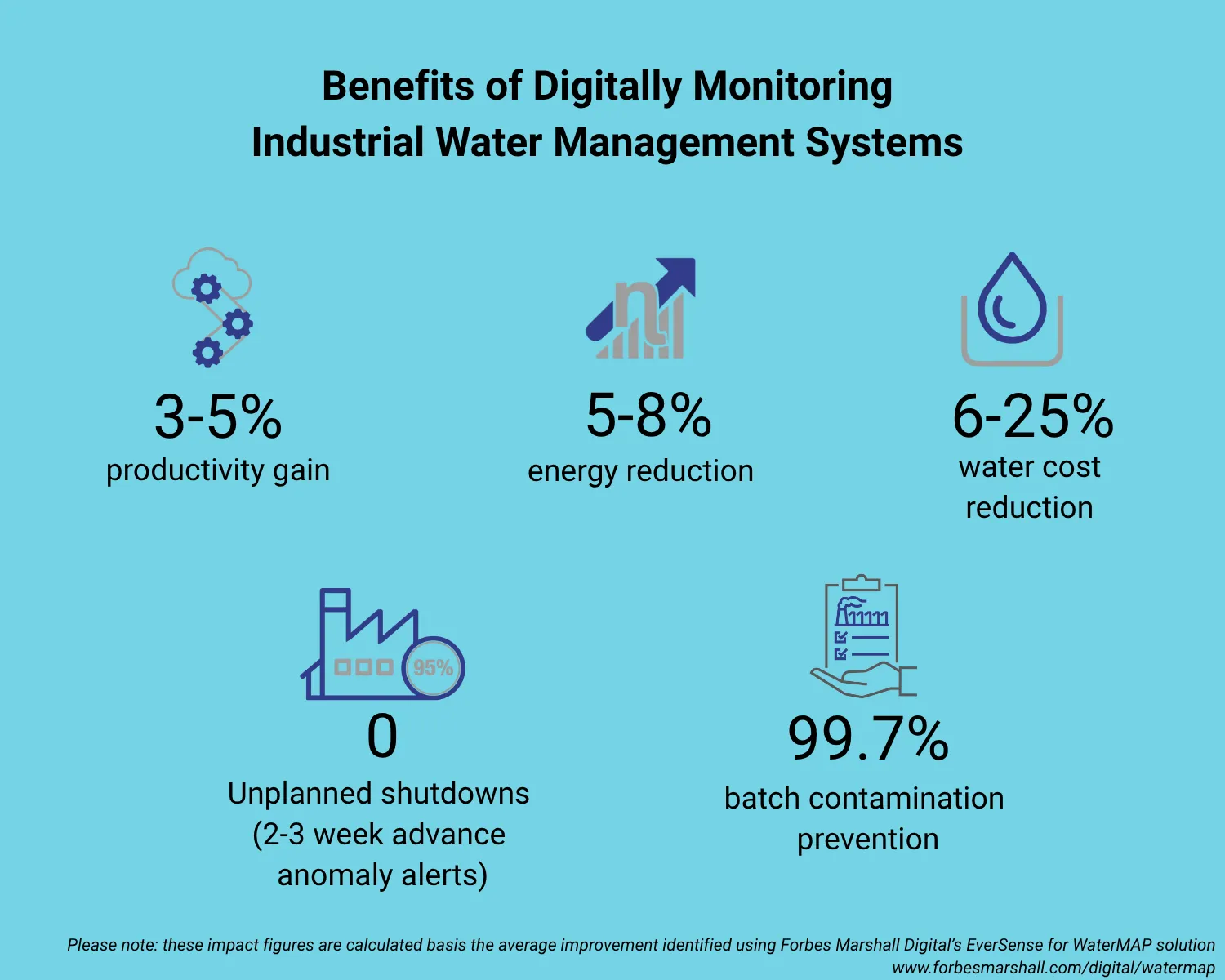

Real Industrial Impact

Automotive: pH drift detection in paint booths prevented rework cycles and maintained 100% paint quality.

Metallurgical Plant: Early detection of cooling valve bypasses recovered 8.5% cooling capacity and reduced pump power by 15%.

Pharmaceuticals & Pigments: Predictive cleaning alerts for heat exchangers maintained 7.2% higher efficiency and improved production by 4%.

Steel Manufacturing: Demand-linked cooling tower optimisation saved 8% fan energy and reduced blowdown by 12%.