Pipe sizing should be done correctly to avoid losses during steam distribution

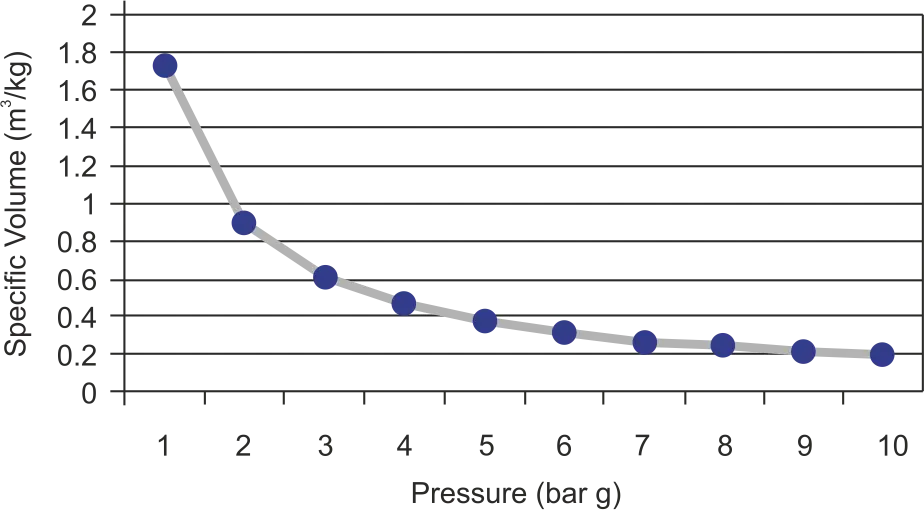

Distribution of steam at the highest possible pressure leads to reduction in piping cost and distribution losses. An increase in steam pressure decreases its specific volume, enabling use of smaller pipes.

The volume of steam decreases with an increase in pressure making it possible to carry same mass of the steam through pipes of a lower bore size.

The use of pipes of lower bore sizes would bring in a significant difference in the day-to-day operations for a plant by reducing the radiation loss (due to lower pipe surface area) and lower material costs on pipes and pipe insulation.

Additionally, distributing steam at a higher pressure facilitates use of smaller, compact pipe racks and supports and hence a more cost effective design.

E.g. : Distributing steam at 8 bar instead of 4 bar saves 20% in piping costs, 15% in radiation loss and 25% in insulation costs (keeping velocity constant at 25 m/s and assuming a required flow of 1.5 tons per hour).