Condensate Contamination Detection Systems (CCDS)

Condensate and flash steam together contain approximately 20% of the heat energy present in steam. Unfortunately, process users are not able to recover their condensate if it gets contaminated or even if there is a possibility of contamination due to leakage in the process vessel or because of any other reasons. Conventionally, contaminated or assumed to be contaminated condensate is drained which leads to wastage of water as well as energy.

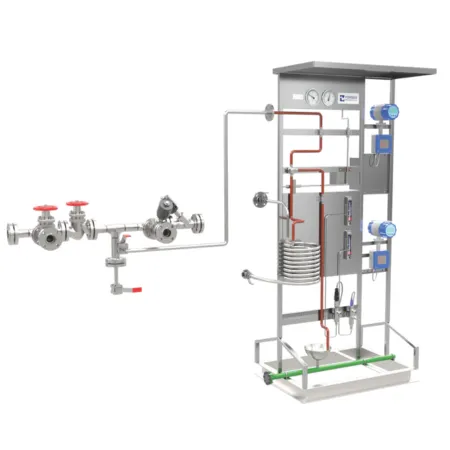

Condensate Contamination Detection System is a conductivity and pH based system from Forbes Marshall. CCDS will check the condensate for any contamination. If the condensate is not contaminated, it will be re-utilised again as normal condensate. In case the contamination is detected, CCDS will divert the condensate to a plate heat exchanger for indirect heat recovery post which the condensate is drained.

- Fully automated system which works independently without any manual supervision.

- Easy to integrate with existing condensate recovery system.

- Temperature compensation sensor gives accurate results regardless of condensate temperature.

Frequently Asked Questions

The most common cause of condensate contamination is leakage in the process equipment.