QSWAS™ – The Ideal Solution For Retrofitting & Upgrading SWAS Systems

Corrosion and deposition are major threats that destabilize power plants, reducing not only efficiency and output but also the effective life of critical equipment. Impurities in steam and water—such as conductivity (specific, cation, and degas), pH, dissolved oxygen, silica, phosphate, sodium, and chlorides—are the root cause, leading to corrosion, deposition, failures, and costly, unplanned shutdowns.

Why Steam and Water Analysis Systems (SWAS) Essential?

In a power plant, impure steam and water can affect process efficiency. Steam and Water Analysis Systems or SWAS help plant personnel keep a watch on critical parameters, and help them take corrective actions that enhance the life of critical equipment like pressure parts, heat exchangers and turbines. An effective SWAS also helps reduce maintenance costs and downtime. However, a large number of plants and boiler users either don’t have online steam and water analysis systems, or the systems they have are complicated to operate.

Common Challenges with Traditional Steam and Water Analysis Systems (SWAS)

- Large Footprint: They are often large, complicated, and consume a vast amount of valuable floor space.

- Maintenance Nightmare: Not ergonomically designed, making them difficult to access and maintain.

- Costly Upgrades: Stage-wise upgrades are often not feasible, requiring large, one-time investments for modernization or replacement.

- High Manpower Demand: Require additional staff for regular maintenance and calibration of the analyzers.

- Complex Sampling: The sheer volume of sampling components results in a very large sampling system footprint.

Why is QSWAS ™ Better

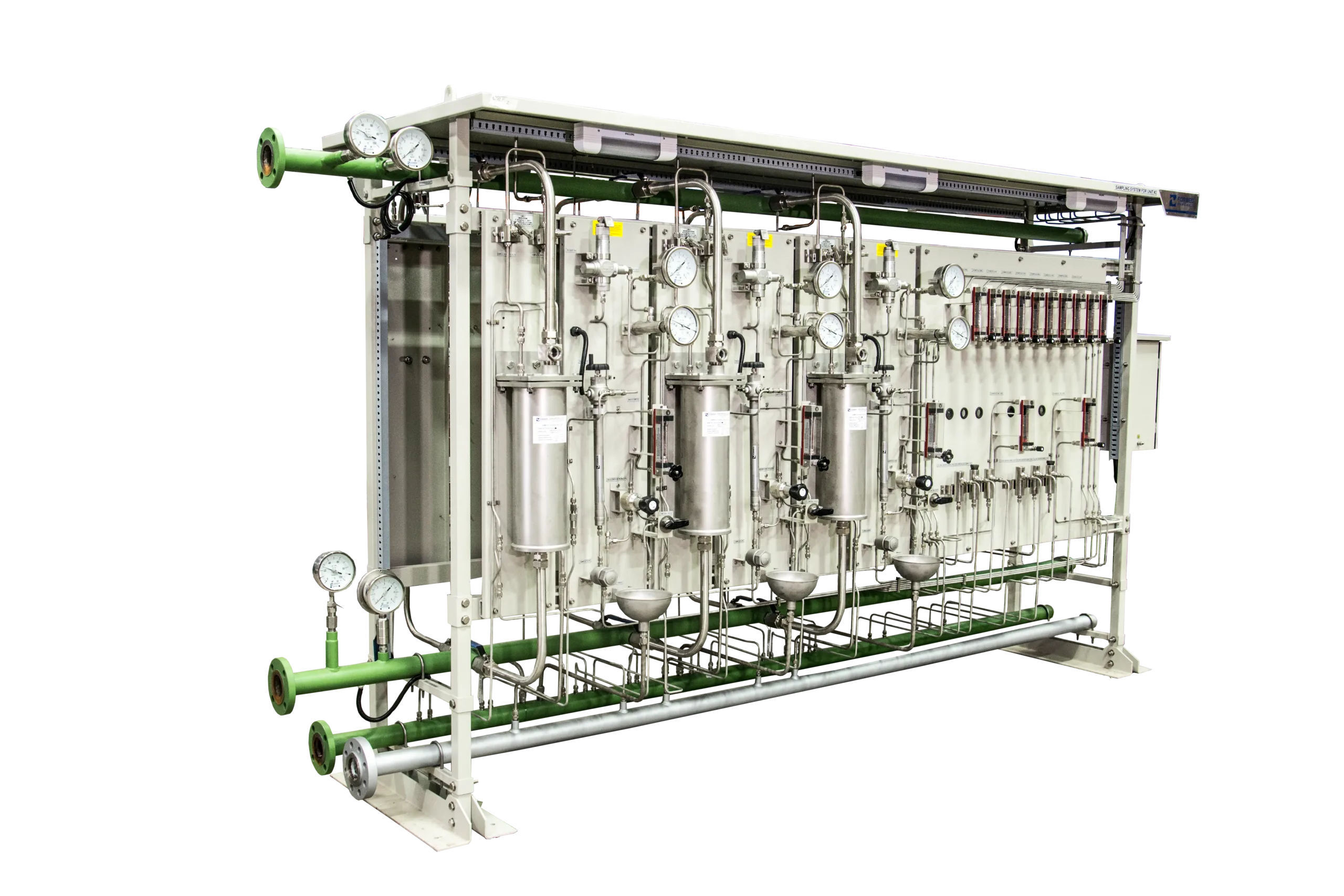

Image: QSWAS™ – Steam and Water Analysis System

The Forbes Marshall QSWAS ™ is the breakthrough modular sample handling system specifically engineered to solve all these challenges. If you are considering SWAS system retrofitting or a full upgrading SWAS systems project, the QSWAS™ stands out as the ideal SWAS system solution.

Designed strictly in line with ASME PTC 19.11-2008 Standards, the QSWAS™ system features multiple components seamlessly assembled on modular structures. This design makes the QSWAS™ easy to install, operate, and, most importantly, maintain.

Core Components of the QSWAS™ :

- Sample Coolers: Designed in line with ASME PTC 19.11-2008 and ASME Section VIII standards, with both mechanical and thermal designs validated by a third party for utmost safety and reliability.

- Rod-in-Tube Type Pressure Reducers: Provide the combined function of pressure reduction and flow modulation, used alongside a back pressure regulator.

- Mechanical Temperature Shut-Off Valve: Ensures automatic protection against dangerous temperature overshoot.

- Degas Conductivity Measurement System: Optimizes CO2 removal for highly accurate conductivity measurement in ultrapure water applications.

- Versatile Controllers: Single or dual-channel options for monitoring pH, Redox, Conductivity, and TDS.

Benefits of Chooding QSWAS

The QSWAS ™ is a completely customizable and flexible solution that allows for easy expansion to suit your plant’s ever-changing requirements. Here is exactly why QSWAS is better than traditional systems:

- Smaller Foot Print : Less space more utilization.

- Easy to Maintain : All components of QSWAS™ are easily accessible from both sides of the SWAS Panel.

- Quick Installation : Standard modular design helps cut lead time for fabricated panels and also integrates complete functionality.

- Expandable : Possible to add more sample or analyzer lines at any point to meet growing requirements

- Layout Flexibility : Modular design for layout ? Flexibility. The SWAS room can be customized according to available space and utility connections.

- Minimal Infrastructural changes : No major infrastructural changes are required when replacing existing systems with the QSWAS ™ .