Analyser downtime caused by lagging maintenance schedules? Optics contaminated? Establish a maintenance schedule based on data.

In emissions monitoring, accuracy is essential. An incorrect reading can misguide operational decisions and lead to regulatory violations. Among the many factors that impact analyser performance, one of the critical issues is optics contamination.

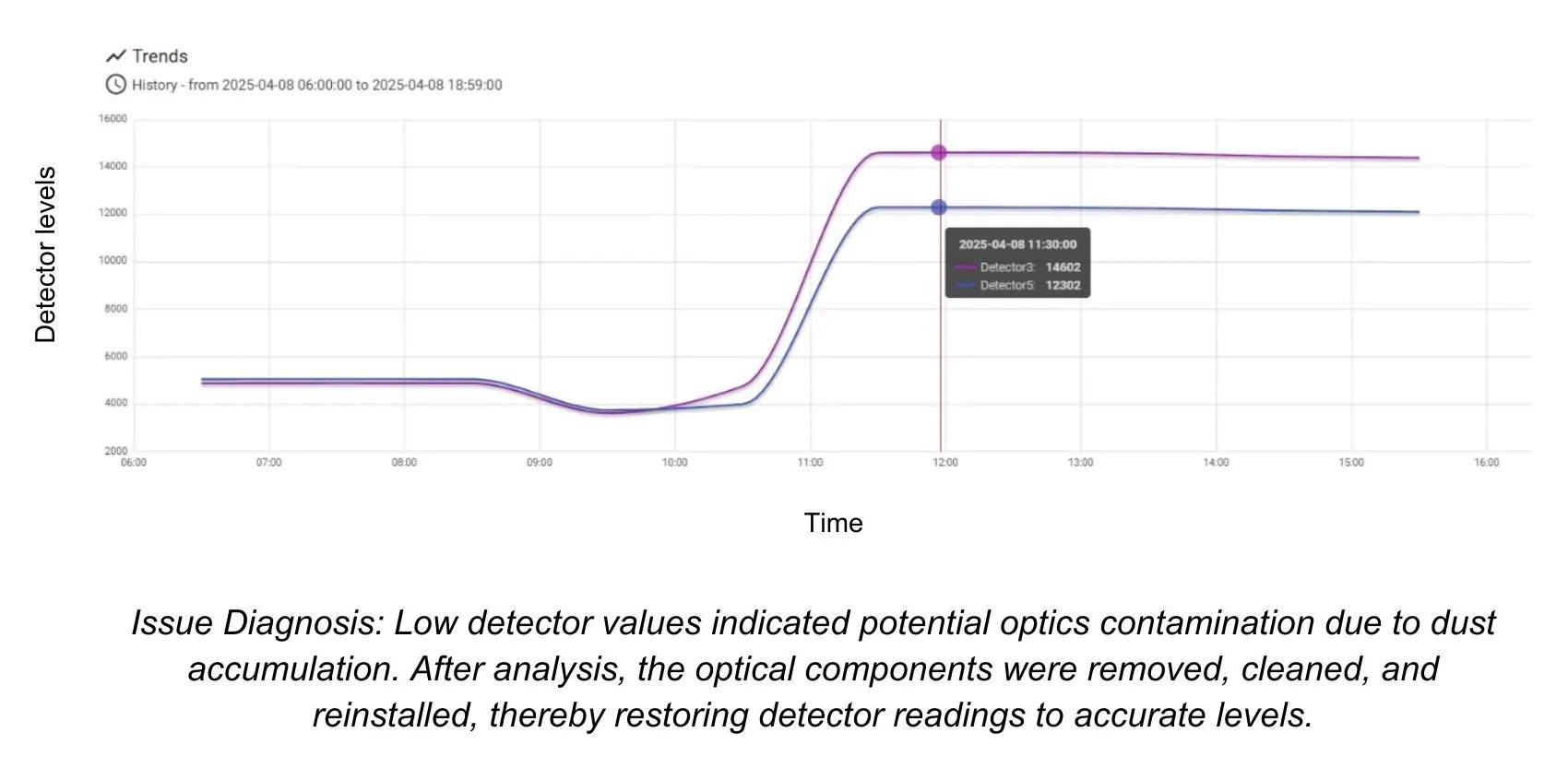

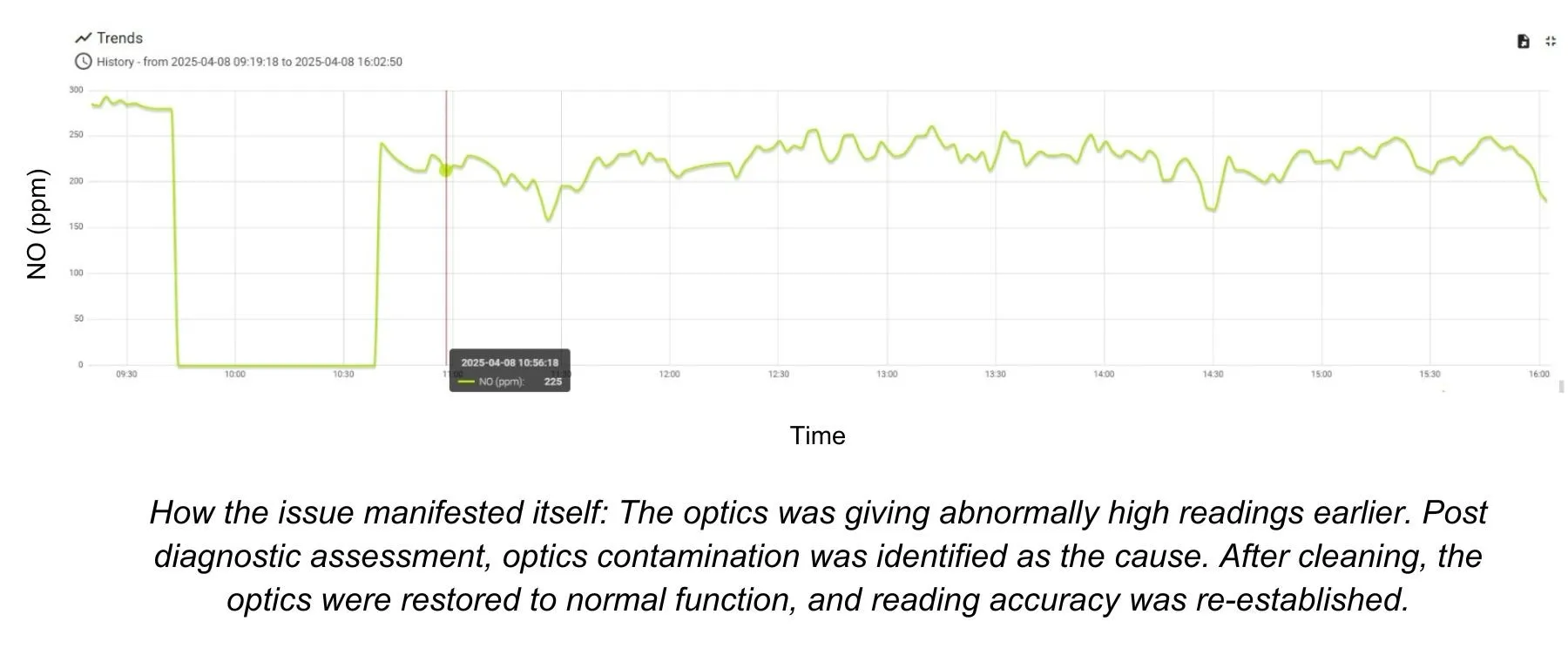

Inside the probe, where flue gas is collected, a ray of infrared light is periodically passed through the sample. This light is reflected back by a precision mirror, and the system analyses the intensity of the reflected signal to determine the concentration of gases like carbon dioxide and sulphur dioxide, nitric oxide, carbon monoxide, water vapor etc. These gases are tightly regulated, and even minor deviations beyond permissible limits can result in a breach of compliance. However, if the reflector mirror gets contaminated, the intensity of the reflected light alters, not because of changes in gas concentration, but due to contamination on the optics. This results in inaccurate measurements, often mimicking high pollutant levels or masking real ones, putting both the plant and the environment at risk.

The good news is, this issue is fully preventable with timely maintenance. Removing, cleaning, and refitting the optical components restores measurement accuracy. Yet in most plants, this maintenance is either reactive or delayed (in terms of the maintenance schedule), leading to sudden downtime and, in some cases, the need to replace the optics entirely.

Forbes Marshall Digital‘s EverSense for CEMS solution informs the user about the ideal maintenance schedule. By continuously monitoring the health of the optics, we can detect early signs of contamination and alert users. This ensures measurement accuracy and extends the life of the analyser components. This targeted maintenance approach also avoids unnecessary interventions and drastically reduces the chance of sudden failures. Users benefit from higher uptime, lower lifecycle costs, and, most importantly, maximum measurement accuracy, ensuring they stay compliant with regulatory standards.

At Forbes Marshall Digital, we go beyond detection — we partner with you to make maintenance smarter, faster, and more effective. Connect with us or read more here.