Does operating a boiler at part load impact it’s efficiency?

One of the major issues of operating boilers is operating it at significantly lower loads than designed. While this might seem harmless on the surface, it comes with hidden costs that can impact both performance and fuel efficiency.

At partial load, a boiler’s fuel consumption doesn’t scale down proportionally. This means that while steam output is lower, fuel usage remains relatively high, leading to a steam-to-fuel (S:F) ratio that drops by 5–15%. Simply put, more fuel is being consumed to generate less steam. Over time, this inefficiency adds up. This situation is triggered by the boiler’s cyclic operation. These cycles cause considerable heat loss, further increasing fuel usage and reducing uptime. The boiler appears to be functioning normally, and inefficiencies like these often go unnoticed or are presumed to be normal.

This is where EverSense for Boiler Efficiency, a Forbes Marshall Digital solution comes in.

We analyse real-time boiler performance and correlate it with plant loading conditions. With this analysis, we’re able to assist customers in identifying how low-load operation is affecting fuel consumption and provide recommendations for the optimal operations. Instead of the operator relying on trial and error, our data and experience-backed approach helps them make informed changes confidently, improving boiler operation and reducing unnecessary fuel loss.

With EverSense for Boiler Efficiency, we turn boiler data into powerful, actionable insights — helping our customers operate smarter, cleaner, and more efficiently every day.

Live Case:

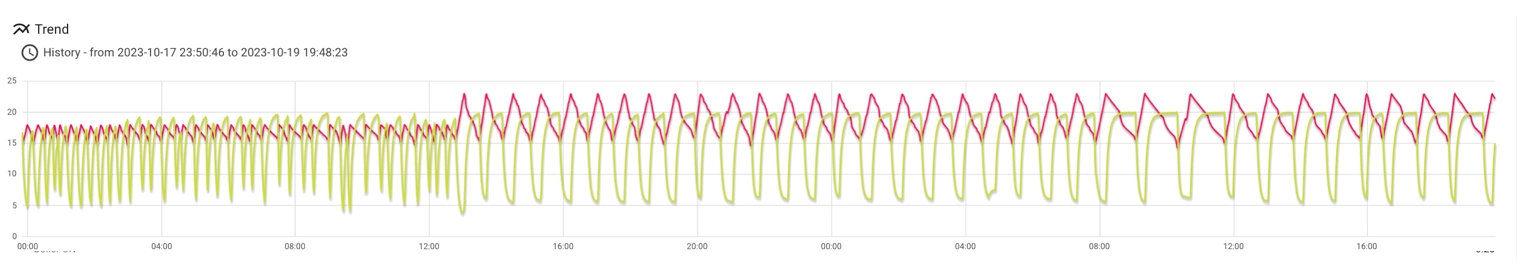

Boiler loading pattern assessment: Detecting the problem

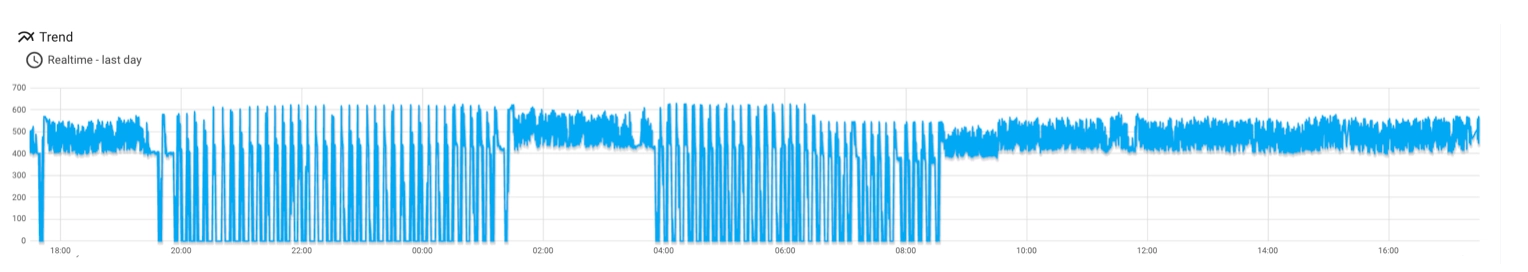

Detecting issues – Higher On/Off cycles in this case: How the problem manifested itself

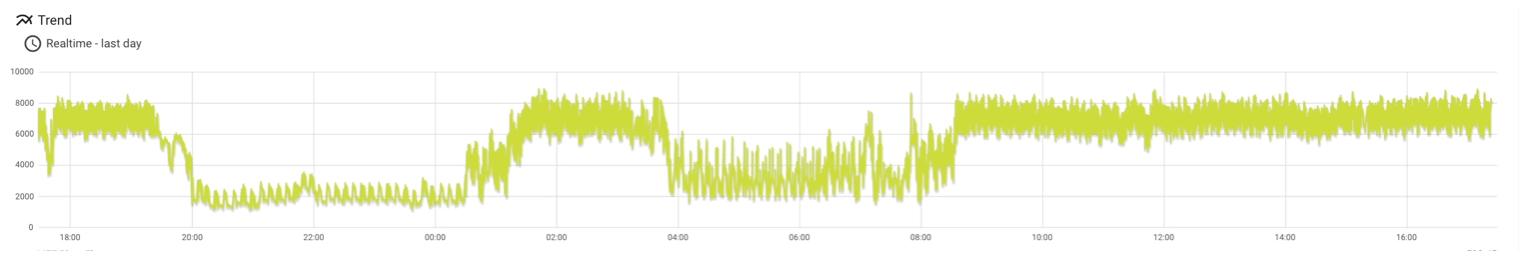

Finding implication of issues observed: How the S:F ratio was affected

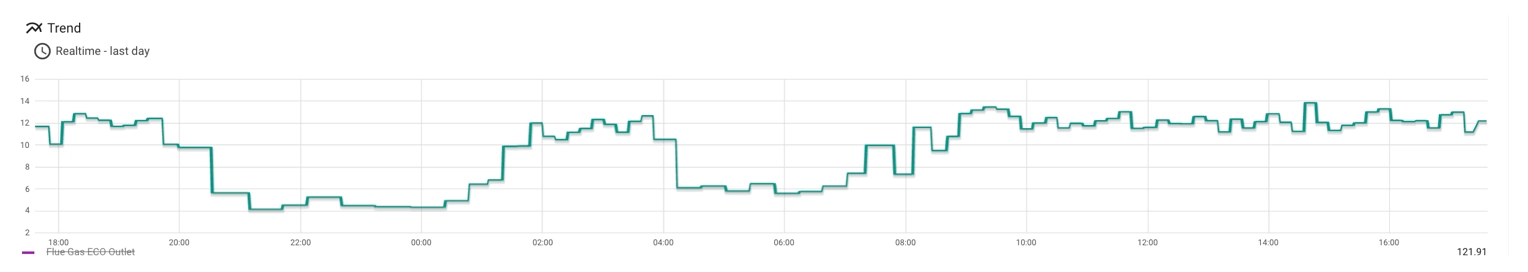

Resolving issues: Post implementing the Eversense for Boiler Efficiency digital solution