The Impact of regulated pressure supply on specific energy consumption and efficiency in Compressed Air Systems

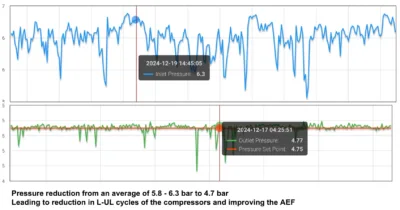

Compressed Air Systems face increased loading-unloading cycles due to fluctuating pressure at the Process Sections or End User. This impacts the overall running specific energy consumption of the compressor due to increase in artificial demand, leading to lower efficiency of the equipment and high energy bills.

Did you know: Compressed air accounts for about 15 – 20% of the overall energy bill.

How can we control these costs?

One can work towards the plant air balance, thereby also lowering the carbon footprint of the plant.

Continuous monitoring of:

- critical parameters (varying pressure, flow, volume and energy) and

- important metrics (specific energy and running efficiency), along with

- introducing an artificial demand controller which can help control and stabilise the varying pressure at the process end by controlling the generation pressure to eliminate artificial demand

These steps can help bring a significant reduction in overall energy costs (i.e. utilities, production and others), which contribute towards the plant Air balance.

Forbes Marshall Digital’s EverSense for Air Energy Factor solution partners with plants to achieve air balance, reduce energy costs and lower their carbon footprint. Learn more here: https://www.forbesmarshall.com/digital/air-energy-factor/