How to Fix Low Recovery in Industrial Water Treatment Caused by Multiport Valve Leakage

In many industrial plants, significant water and energy losses occur within the water treatment plant (WTP), often going unnoticed until a breakdown happens. One of the most common yet overlooked problems is water wastage during filtration and backwash cycles in systems using Pressurised Sand Filters (PSF) and Activated Carbon Filters (ACF). PSF and ACF filters remove suspended solids and odours to maintain feedwater quality for downstream units like RO, softeners, and DM plants. They self-clean through periodic backwashing, where a multiport valve reverses water flow to flush out accumulated impurities from the filter bed.

Consequences of a faulty multiport valve

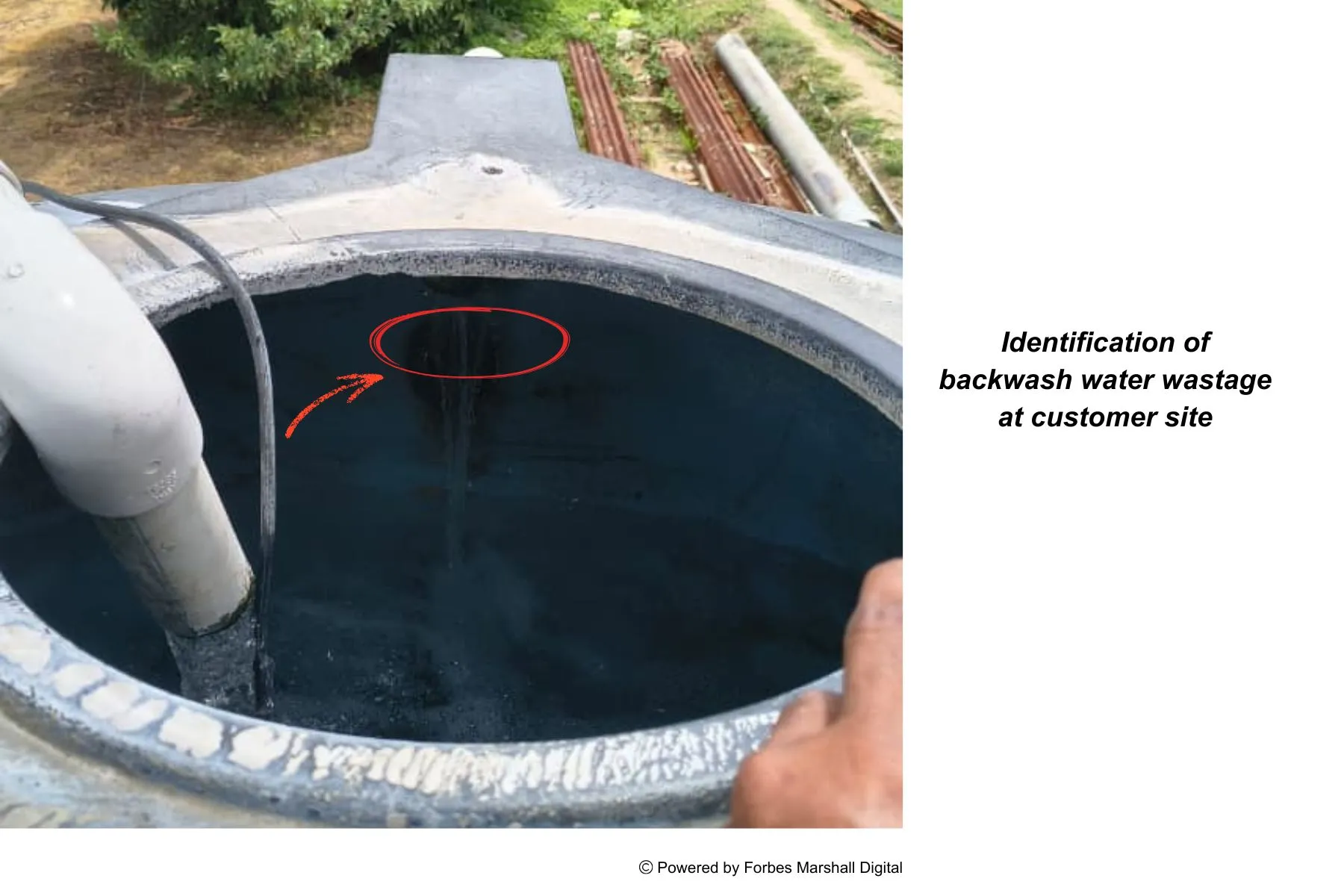

A multiport valve may fail to close completely due to deterioration or stuck particles that prevent a proper seal. As a result, water flows both ways towards treatment and backwash simultaneously, leading to significant wastage and ineffective cleaning. The plant unknowingly loses treated water, energy, and chemicals, while also running below optimal performance levels.

The criticality of the multiport valve functioning correctly

If the backwash and filtration systems functioned as intended, without valve leakages or reverse flow, plants could operate at their optimal efficiency. This would mean no treated water losses, lower chemical and electricity consumption, and consistent RO membrane life. Reliable filtration performance would also ensure stable treated water quality across downstream units like the RO and DM plants. By minimising reject water and maintaining proper valve operation, industries can achieve significant savings while enhancing system reliability and long-term operational sustainability.

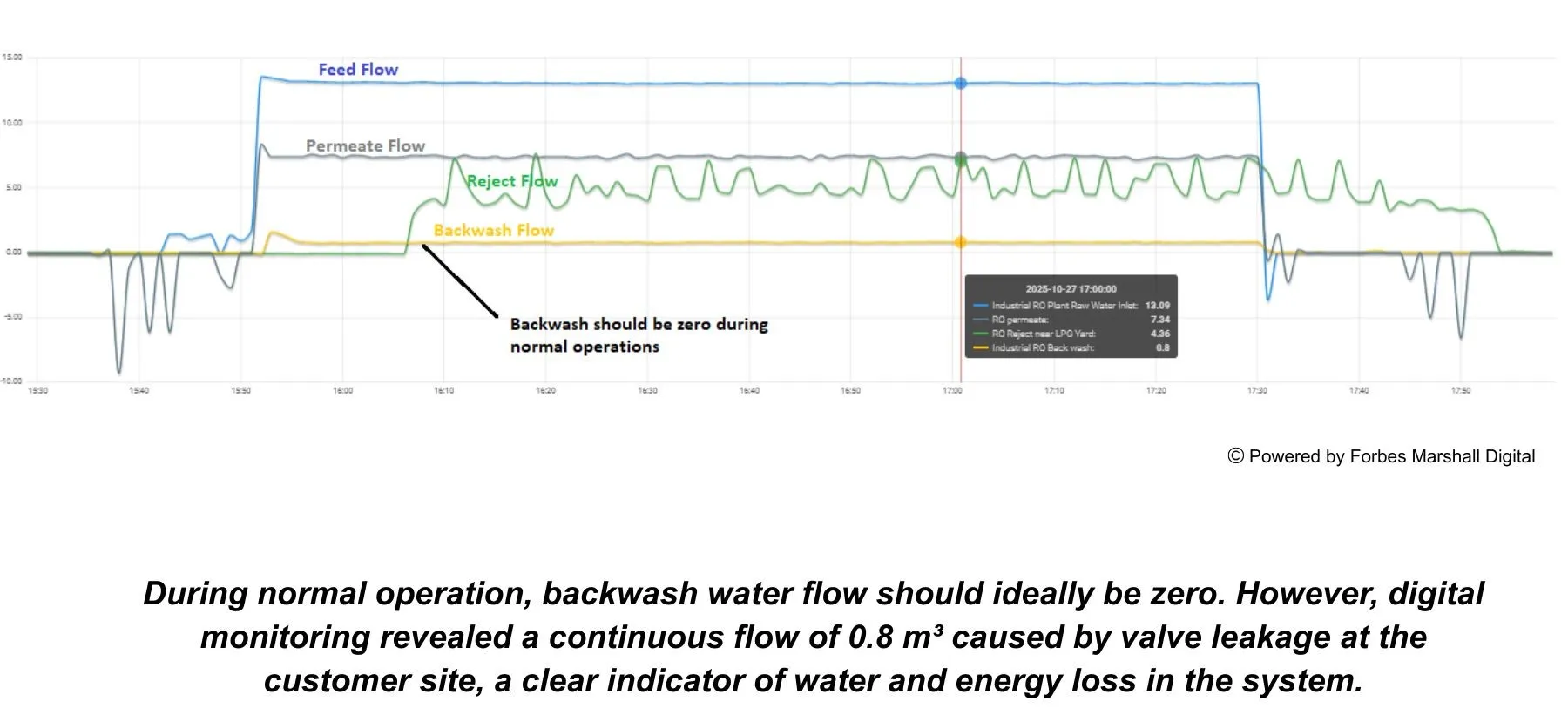

How digital monitoring helps quick identification and rectification of errors in the filtration system

A digital monitoring solution helps by connecting key water treatment assets for real-time performance tracking. Forbes Marshall Digital’s EverSense for WaterMAP solution digitally connects the PSF and ACF inlets, outlets, and backwash lines to continuously capture flow data. This data is securely transmitted to the cloud, where the EverSense dashboard provides real-time visibility of water quantity, quality, and consumption trends across the entire WTP including the PSF, ACF, softeners, RO plant, and DM plant.

Anomalies such as valve leakage, unbalanced flow, or prolonged backwash cycles are detected and flagged in real time, allowing for timely corrective actions (such as repair or replacement of the valve) and data-driven maintenance. Previously, operators could only identify valve malfunctions after a significant issue arose or through manual inspection, which was a task. Now, with data-driven insights and predictive monitoring, plants can maintain a high operating efficiency.