Can high stack temperatures within a boiler reduce efficiency?

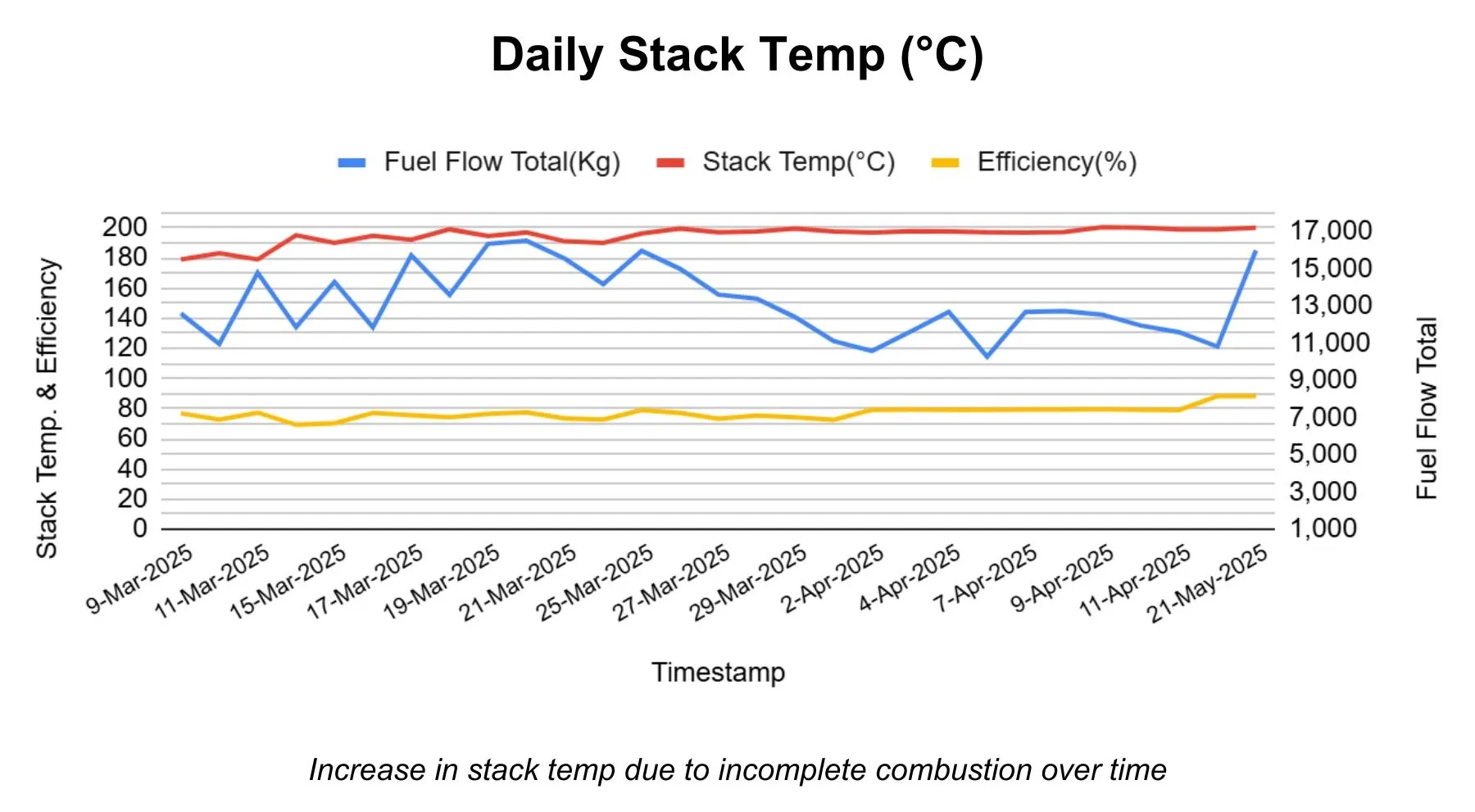

When heat escapes instead of being used within a steam system, efficiency quietly reduces. One major cause? High stack temperatures of a boiler: which is often a result of poor combustion.

Improper combustion can be triggered by low air supply, poor mixing of air and fuel, and/or inconsistent fuel quality. This results in unburnt fuel that clings to the internal surfaces of the furnace and boiler tubes. The result: more heat exits through the stack instead of being absorbed and with it, a 1–3% increase in fuel consumption.

What makes this problem even more gradually harmful is that the boiler may appear to be operating normally, while efficiency drops in the background.

That’s where EverSense for Boiler Efficiency, a Forbes Marshall Digital solution, adds value. Through this we continuously monitor combustion parameters and stack temperatures, helping detect deviations early. Using data patterns, EverSense flags poor combustion conditions or rising stack temperatures, often a sign of fouling. Based on this, our domain knowledge experts provide actionable insights: whether it’s combustion tuning, cleaning routines, or SOP improvements.

Know more about EverSense for Boiler Efficiency here.