How does feedwater tank replenishment impact boiler efficiency?

In a steam system, the feedwater tank plays a quiet but critical role – recycling hot condensate and make-up water. However sometimes, the way in which water is added back into the system can drain efficiency.

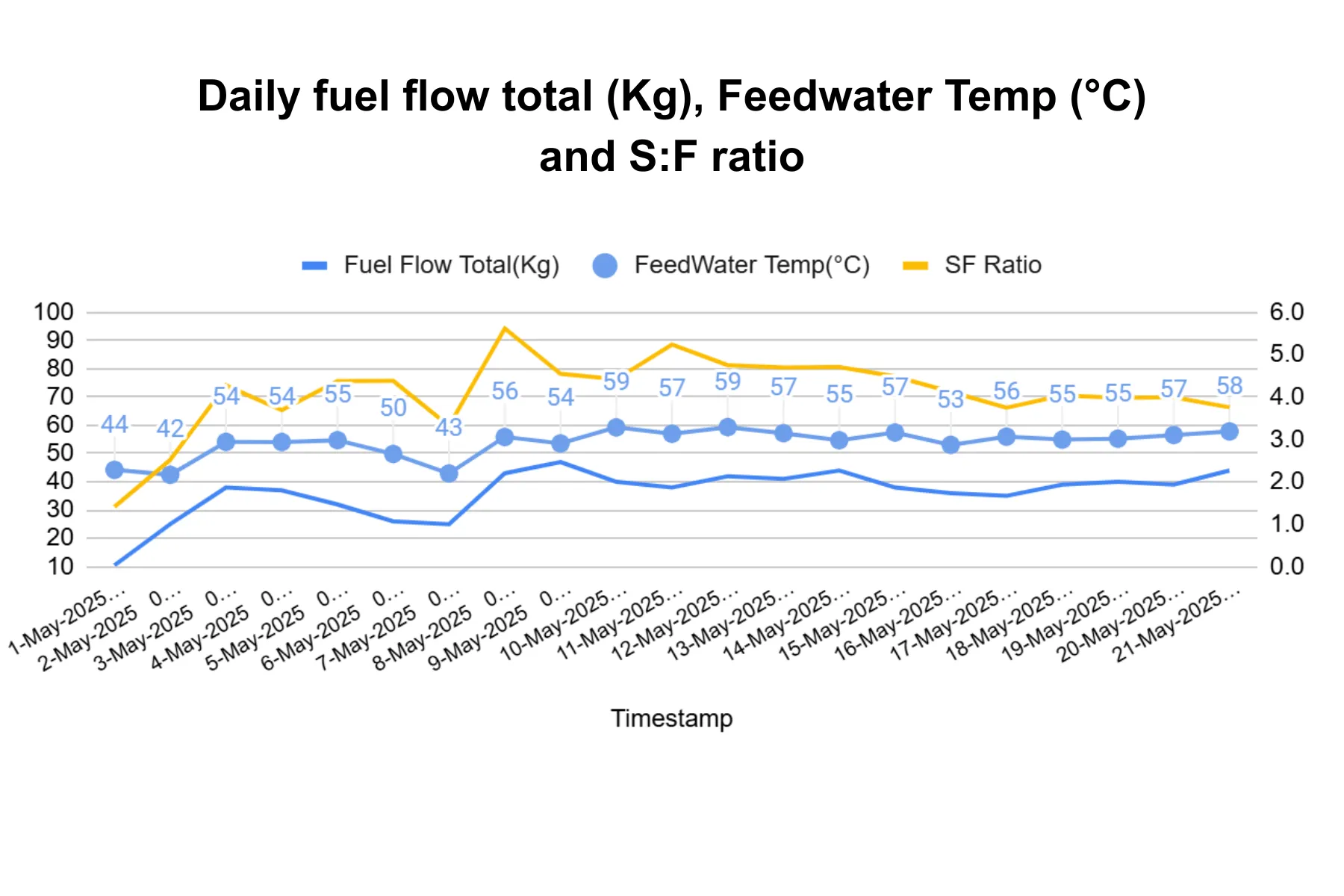

Once the feedwater tank is nearly depleted many plants replenish this water in bulk. When this happens, a large amount of cold make-up water enters the tank in one go, causing a sharp drop in its temperature. This seemingly harmless routine creates a ripple effect: lower feedwater temperature means the boiler has to run longer or at a higher bar to convert this water into steam. As a result there is a noticeable dip in the steam-to-fuel ratio (S:F) and steam generation capacity. Additionally, up to 1–3% more fuel is consumed for the same output.

How a drop in feedwater temperature results in a substantial drop in the S:F ratio

EverSense for Boiler Efficiency, a Forbes Marshall Digital solution, helps draw attention to correct this pattern. We continuously monitor feedwater tank temperature, replenishment cycles, and corresponding boiler performance. Our experts analyse this data, basis the present operating boiler load to recommend a better replenishment approach. For example, switching from bulk replenishment to a controlled, continuous make-up water addition can stabilise tank temperatures and prevent thermal shocks. The result is improved heat transfer, a more consistent S:F ratio, and sustained boiler performance.

Because sometimes, it’s not just what you feed your boiler—but how you feed it—that makes all the difference. Know more about EverSense for Boiler Efficiency here.