Raising the Bar for Breweries: The Benchmarking Journey

Steam plays a central role in brewing, from mashing and wort boiling, to pasteurisation, cleaning, and bottle washing. In fact, mashing and wort boiling alone account for about 50% of the connected steam load in a typical brewery.

With steam alone contributing to over 40% of a brewery’s total utility cost, it presents the single largest opportunity for conversion cost reduction.

The beginning: Benchmarking energy use in breweries

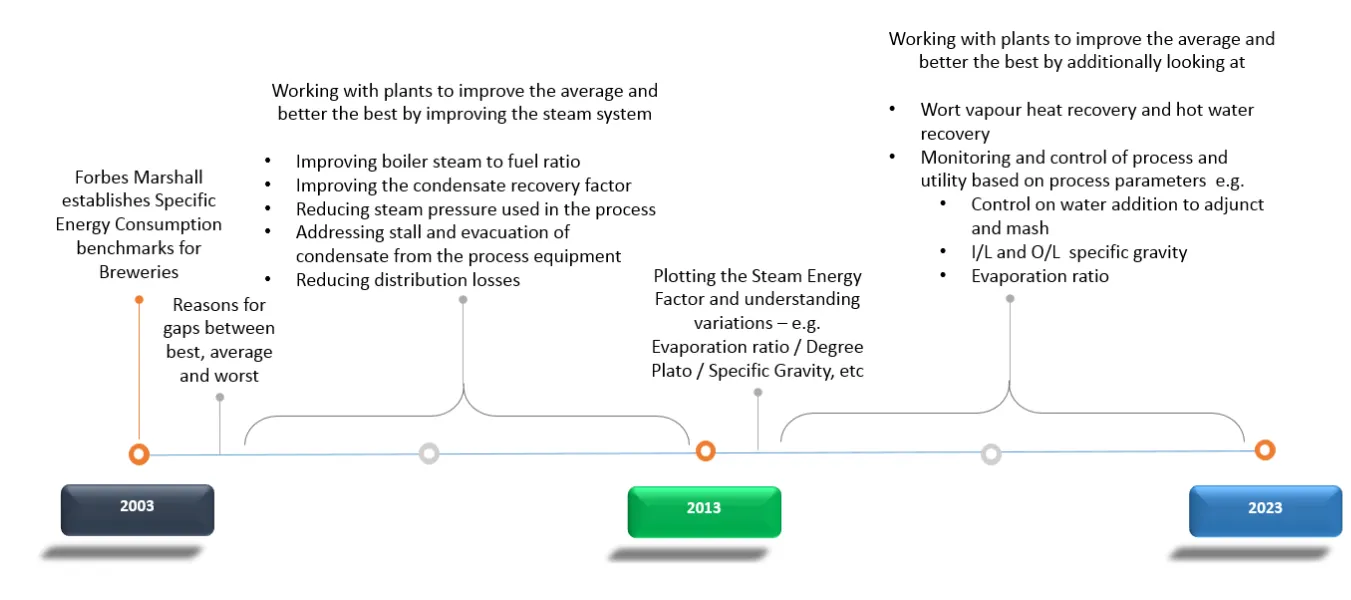

Our journey towards energy-efficient brewing began in 2003, when we pioneered the concept of specific energy benchmarking for breweries in India. By studying energy consumption patterns across multiple plants and identifying the gaps, we partnered with breweries to develop a practical roadmap for improvement.

As the first step, we compared the steam system performance across these breweries to understand what set them apart and put down a roadmap to bridge the gap between average and best in class performance.

What we found

We discovered that variations in specific energy consumption were driven by several interlinked factors:

For example, capacity utilisation and process technology had a direct impact. Breweries operating below 75% of their capacity showed 10–15% higher specific fuel consumption as compared to those operating above 75% capacity. Similarly, plants using external wort boilers were more energy efficient than those relying on internal systems.

However, the largest opportunities for savings lay within the steam system itself. Boiler house improvements alone had the potential to reduce fuel consumption by about 7%, primarily by improving combustion efficiency and minimising blowdown losses. In the distribution network, issues such as incorrect line sizing, inadequate trapping and pressure reduction contributed to higher losses increasing energy consumption. One chronic issue observed in most of the temperature controlled processes was the bypassing of steam traps to remove condensate, which significantly increased steam usage and led to the loss of recoverable condensate. Condensate across most plants was being drained. Even where condensate recovery existed, it was typically limited to the brewhouse, while condensate from the bottle washers, CIP sections and pasteurisers was being drained.

We began by addressing these issues in the steam system to reduce specific energy consumption. Over time, as breweries set more ambitious and challenging targets for conversion cost reduction, our solutions evolved. Our focus shifted from not just looking at the steam and condensate network to looking at the process itself.

Our deep dive into understanding the gap between the theoretical and actual energy requirement led to further avenues for energy optimisation like

- Precise evaporation ratio / degree plato control during wort boiling

- Wort vapour heat recovery for hot water generation

- Energy tank optimisation to minimise thermal losses

- Precision control of utility supply like Adjunct water addition,.

The impact of these joint efforts between breweries in India and us over the last two decades has been significant. For example, energy consumption reduced from 247MJ/HL to about 85MJ/HL. Without these interventions energy use today would have been 65% higher than 2003 levels), and 33% higher from 2021 levels). This has directly led to a similar percentage reduction in CO2 emissions.

Similarly, improving condensate recovery has cut boiler make up water by about 70% over 2003 levels.

There’s still room to brew better. Our global assessment shows that, even today, breweries can reduce energy consumption by an average of 21% using widely available, cost-effective technologies. The numbers tell a clear story: optimising steam systems and process utilities remains one of the most impactful ways to cut costs and emissions. With the right approach and proven solutions,breweries can unlock meaningful gains in efficiency, cost savings, and sustainability.