Objective:

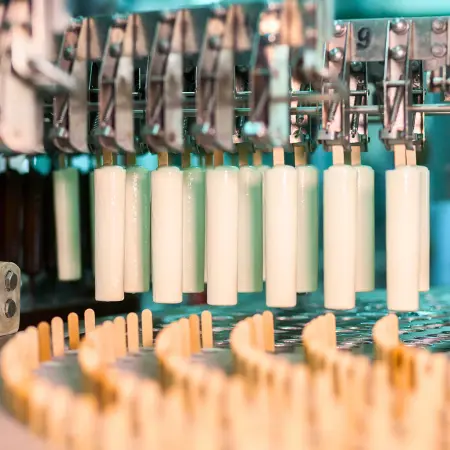

Forbes Marshall surveyed a plant in Malaysia of a leading multinational food processing group. The objective of the survey was to save energy by recovering flash steam which was being vented and by improving the feed water temperature which was only 50⁰C.

Solutions:

Through a detailed study of the plant, our team established the quantity of flash steam being vented and the potential for improvement in the condensate recovery factor. Furthermore, our engineer also carried out a heat mass balance of the feed water tank to assess the impact of recovering condensate and flash steam to the feed water tank. Our team provided the plant inputs, studied the issues thoroughly and implemented the best practices in the plant. Two suitable pumps and temperature control valves were installed to overcome the crisis.

Benefits:

a. The feedwater temperature was increased to 80⁰C, from the previous 50⁰C.

b. The flash steam was completely recovered from previously being wasted.

c. The steam-to-fuel ratio improved from 13.02 to 13.76.

d. Fuel savings achieved was 260.9 kilolitres per annum.

e. Monetary savings made was 120,704 USD/year.