Tank Farms

Tank farms are used to store a wide range of raw materials and finished products across industry segments. Given the large number of tanks and diverse materials, it is important to consider efficient utilisation of tank space, proper inventory management to prevent shortages or overstocking, and avoid wastage due to spills, leakages and overflows with minimal manual intervention.

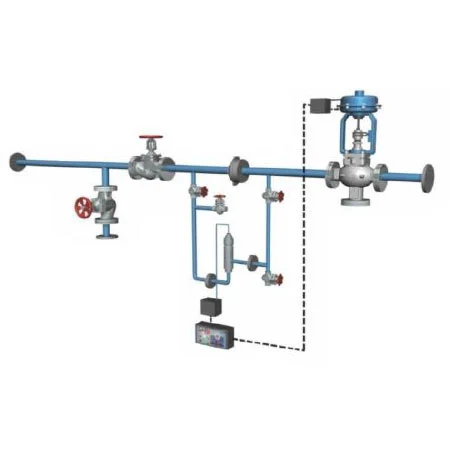

In many cases steam heating and tracing is required to heat or trace these product or raw materials within the storage tanks and pipelines at a specific temperature, so as to keep them in a fluid state for easy pumping and distribution. This process reduces viscosity and prevents crystallisation or solidification.

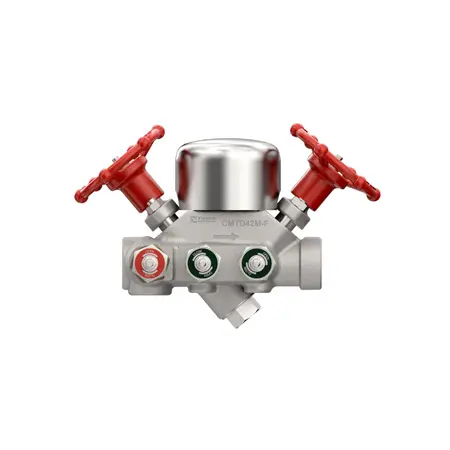

Often, plants face challenges such as failing to reach the desired temperature, delays in temperature attainment, temperature overshoots, water hammering and tank coil punctures in storage tanks. Other common issues include problems with condensate evacuation from tank coils and tracers, excessive steam consumption in the heating and tracing network, contamination of condensate from tanks and tracers and losses due to open trap bypasses.

Our Solution:

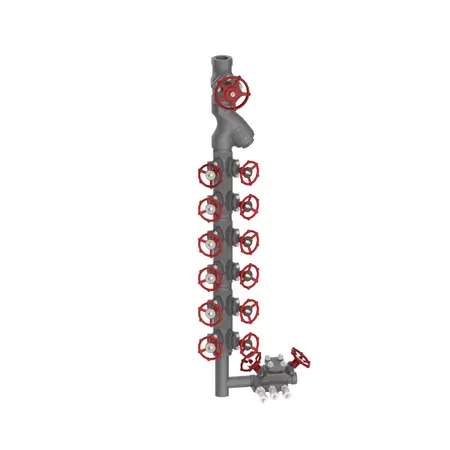

Forbes Marshall’s comprehensive solution for storage tanks and tracing networks includes