Steel Milling

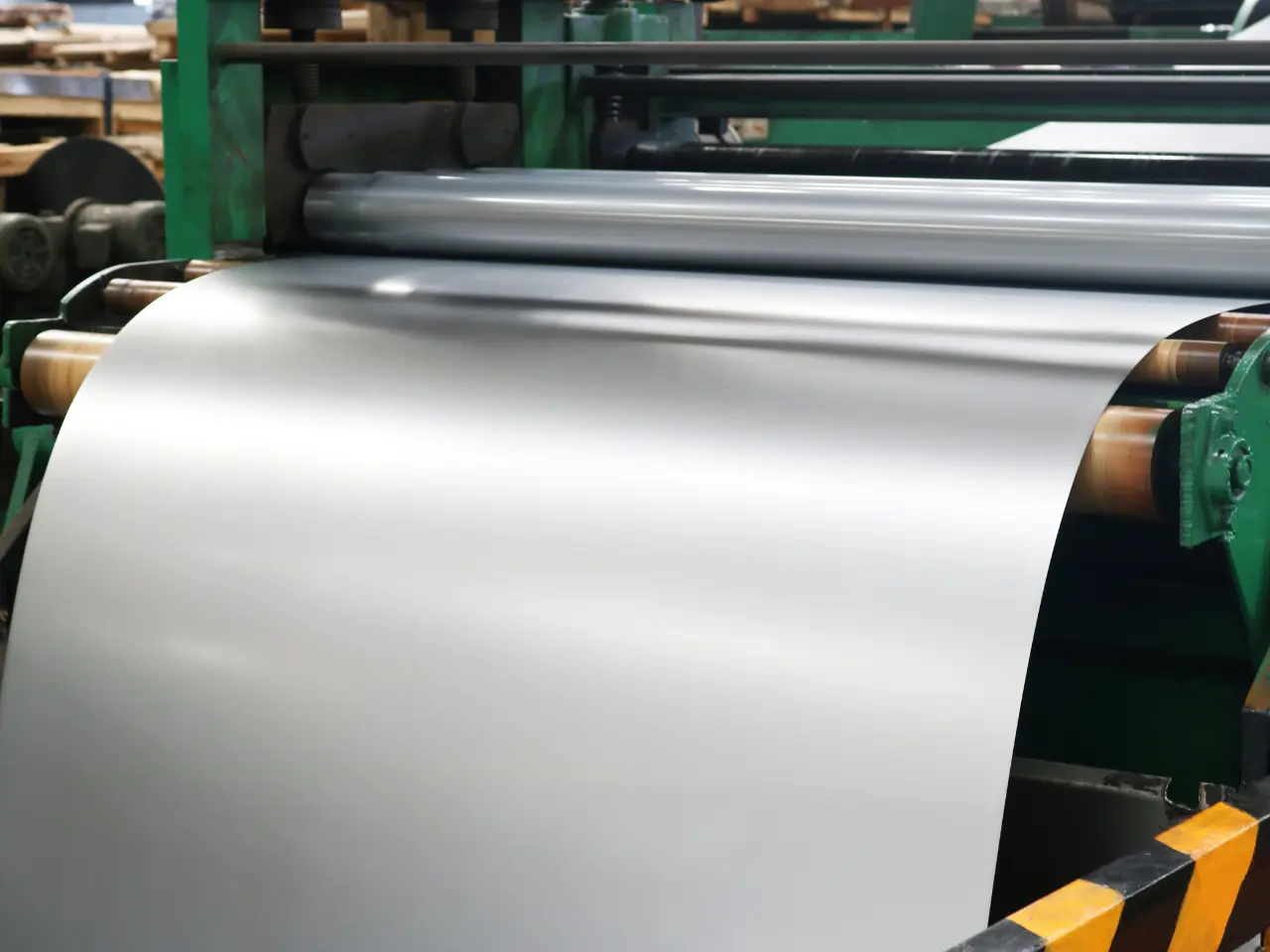

Steel milling focuses on shaping and finishing the solidified steel from the steelmaking process into various semi-finished or finished products. The input for milling is usually solid steel, typically in the form of blooms, billets, slabs, or ingots, produced from continuous casting or ingot casting. This input is transformed into desired shapes and sizes through rolling, forming, and other mechanical processes.

Hot Rolling involves steel being passed through a series of rollers at high temperatures to reduce its thickness and achieve desired shapes like sheets, plates, bars, and structural sections while Cold Rolling further reduces the thickness of hot-rolled steel at room temperature, improving surface finish and dimensional accuracy.

Forming involves processes like bending, drawing, and pressing are used to create specific shapes and components.

The finishing section includes processes like cutting, straightening, and surface treatments to achieve final dimensions and quality.

Typical problems faced in steel milling include:

- Improper condensate evacuation due to stalling

- Manual opening of bypass

- Uncontrolled jet pressure leading to uneven coating

- Improper finished goods quality

- Unplanned downtime due to manual processes and lack of predictive maintenance systems

- Variation in key parameters like pressure and temperature leading safety and load variation issues

Our Solution:

Forbes Marshall solutions in the steel milling section include: