Is your Feedwater tank venting steam and profits into thin air?

In steam systems, condensate is gold. The more you recover and return, the less fuel, water, and energy you consume. But even well-designed systems can quietly lose efficiency, and it often starts with something as seemingly small as how your feedwater tank is managed.

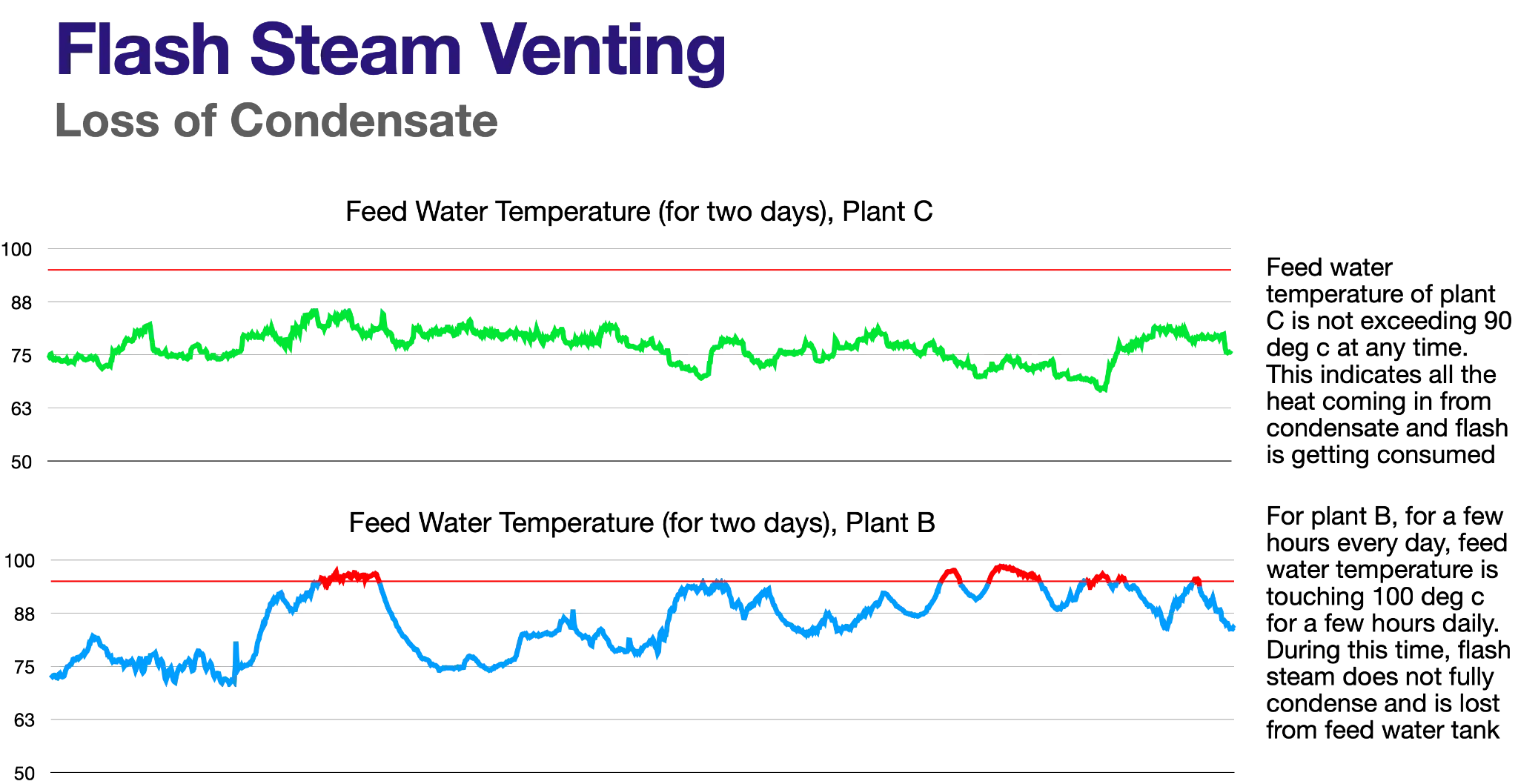

One common but often overlooked issue is high feedwater tank temperature which leads to direct steam loss from the tank itself.

Ideal Feedwater Temperature vs. What happens when temperature hits 100°C

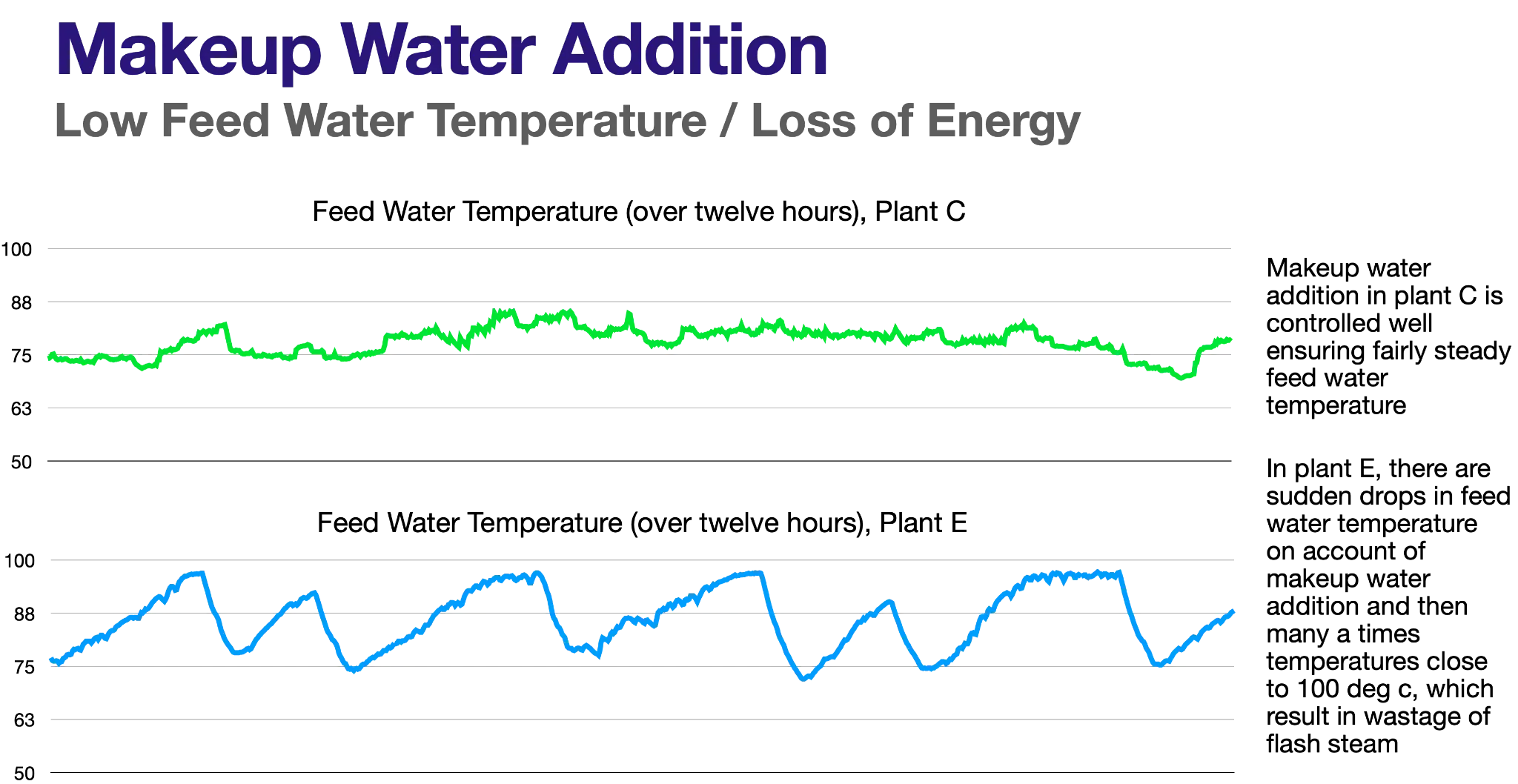

Here’s what typically happens: condensate and flash steam return from the process side at temperatures close to 100°C / 212°F. If make-up water (used to balance the total feedwater volume) is added only occasionally, it doesn’t cool the tank contents enough. As a result, flash steam escapes through the vent, wasting valuable energy.

How Make-Up Water Strategy Impacts Feedwater Temperature — and Steam Loss

The solution isn’t just to keep adding more cold water, it’s about adding water in sync with your boiler’s actual operating load, more frequently and in a way that stabilises tank temperature. However, boiler loads fluctuate during the day proving static settings inefficient.

This is where EverSense for Condensate Recovery Factor, a Forbes Marshall Digital solution, delivers real value.

By monitoring the boiler and condensate system in real-time, our team helps you optimise your feedwater tank based on current operating conditions. It picks up on patterns like elevated tank temperatures, giving you clear, actionable insights to correct the imbalance. Whether it’s adjusting the frequency of water addition or fine-tuning how the tank is being replenished during different load cycles, these small shifts lead to significant savings.

With better feedwater tank management, steam loss through venting is minimised, condensate recovery improves, and you reduce both fuel and water consumption. The result? Lower steam generation costs, reduced environmental impact, and a more sustainable system — all without any major infrastructure change.

At Forbes Marshall, we believe efficiency lies in the details. With EverSense for CRF, we bring those details to the surface, so your team can make informed decisions that keep performance high and losses low.