The hidden cost of ageing infrastructure: How leaky pipes drain your CRF

In steam systems, not all losses are loud. Some escape quietly– through rusted pipes, old joints, and unnoticed leaks. Especially in older plants, where condensate return lines have aged alongside the equipment, such wear and tear can lead to a silent but steady drop in Condensate Recovery Factor (CRF).

Over time, these leaks cause high-temperature condensate to be lost before it reaches the feedwater tank. This not only reduces the amount of reusable water in the system but also leads to a 1–3% increase in fuel consumption. When this goes undetected, the cost of steam generation rises and efficiency quietly slips.

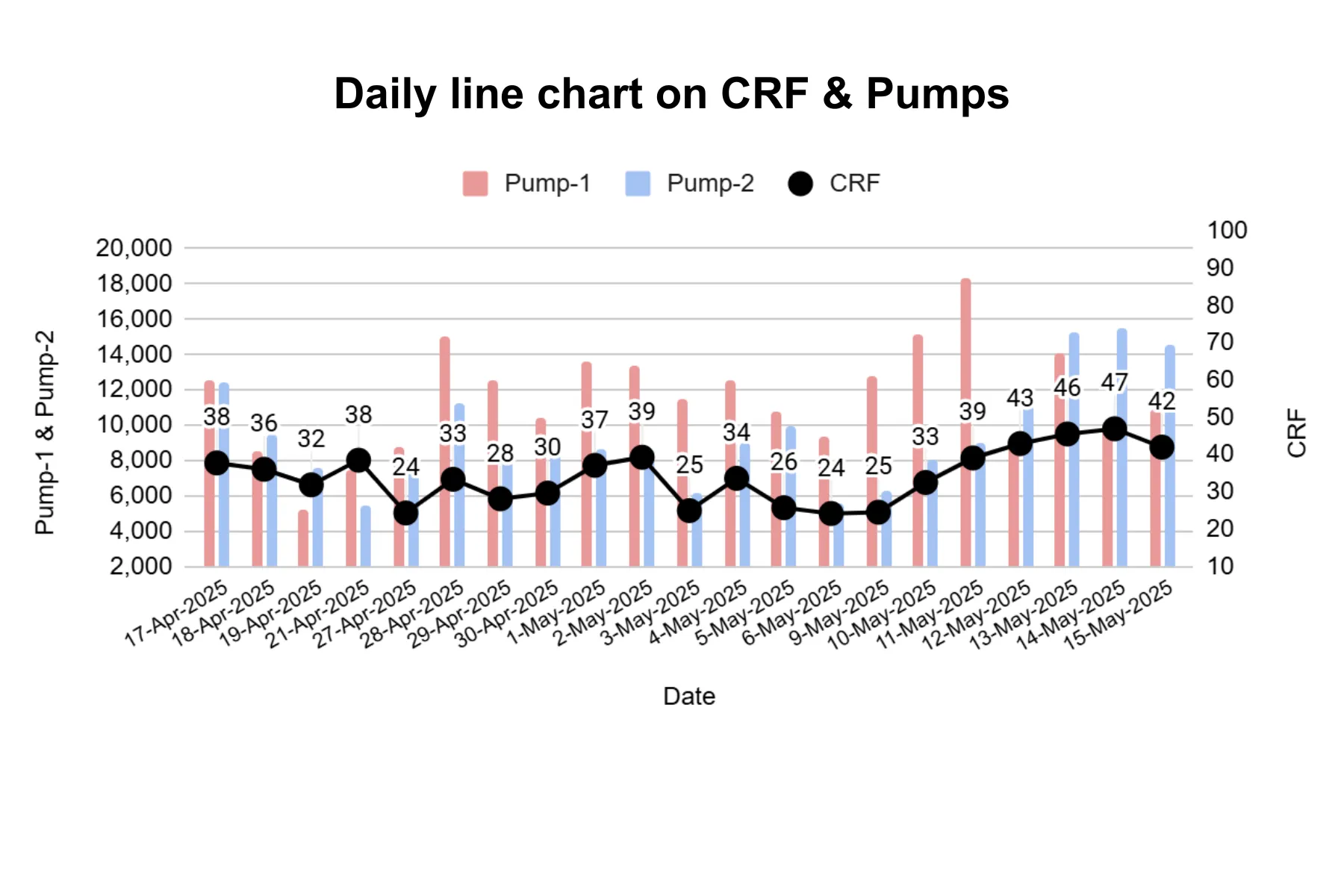

Condensate returned by individual pumps and it’s corresponding daily CRF

EverSense for Condensate Recovery Factor, a Forbes Marshall Digital solution, helps identify and address this problem. By monitoring the condensate network in real-time, we flag anomalies in expected return volumes and heat patterns. This data points to specific zones within the plant where losses are likely occurring.

Our domain knowledge experts then work with your teams to isolate the issue – whether it’s leaking pipes, loose joints, or faulty valves. Clear recommendations are made, training is provided where needed, ensuring quick corrective action– restoring CRF, saving fuel, and extending the life of the system.