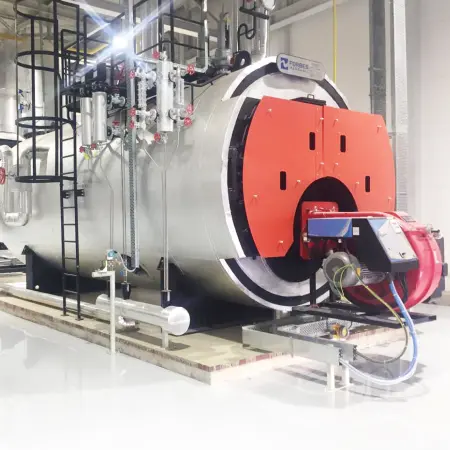

Whether it’s milk, powder, curd, yoghurt, icecream or clarified butter(ghee), every dairy product demands precision, hygiene, and energy efficiency at every stage of processing. Managing heat and energy is critical to ensure the highest product quality, control costs, and drive sustainable operations.

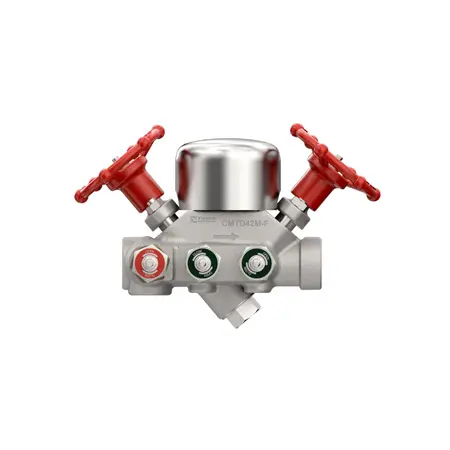

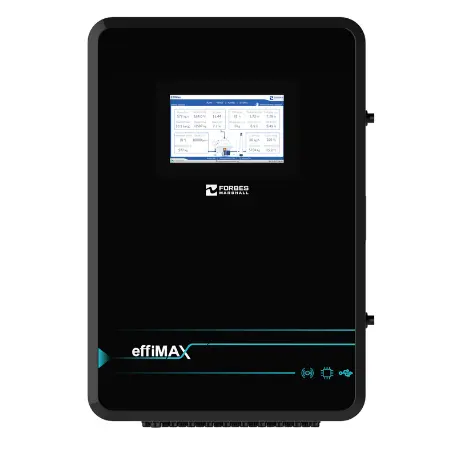

Forbes Marshall offers innovative solutions for pasteurisation, drying, heating, washing, CIP, and storage and filling. Our offerings include advanced boiler controls, steam accessories, flow and level meters, control valves, water quality analysers, condensate recovery systems with an emphasis on energy conservation, process efficiency, and sustainability.

Let us help you