Boiler efficiency improved by 3.75% for a pharmaceutical manufacturing plant in India using FM Digital

A pharmaceutical manufacturing plant in Maharashtra, India was facing variations in its boiler efficiency. Their partnership with Forbes Marshall Digital began in April 2025 with a shared objective of improving and sustaining boiler efficiency using EverSense for Boiler Efficiency, a Forbes Marshall Digital sustenance service.

PROBLEM

Boiler operation was unstable, with frequent ON/OFF cycling (5-6 cycles per hour).

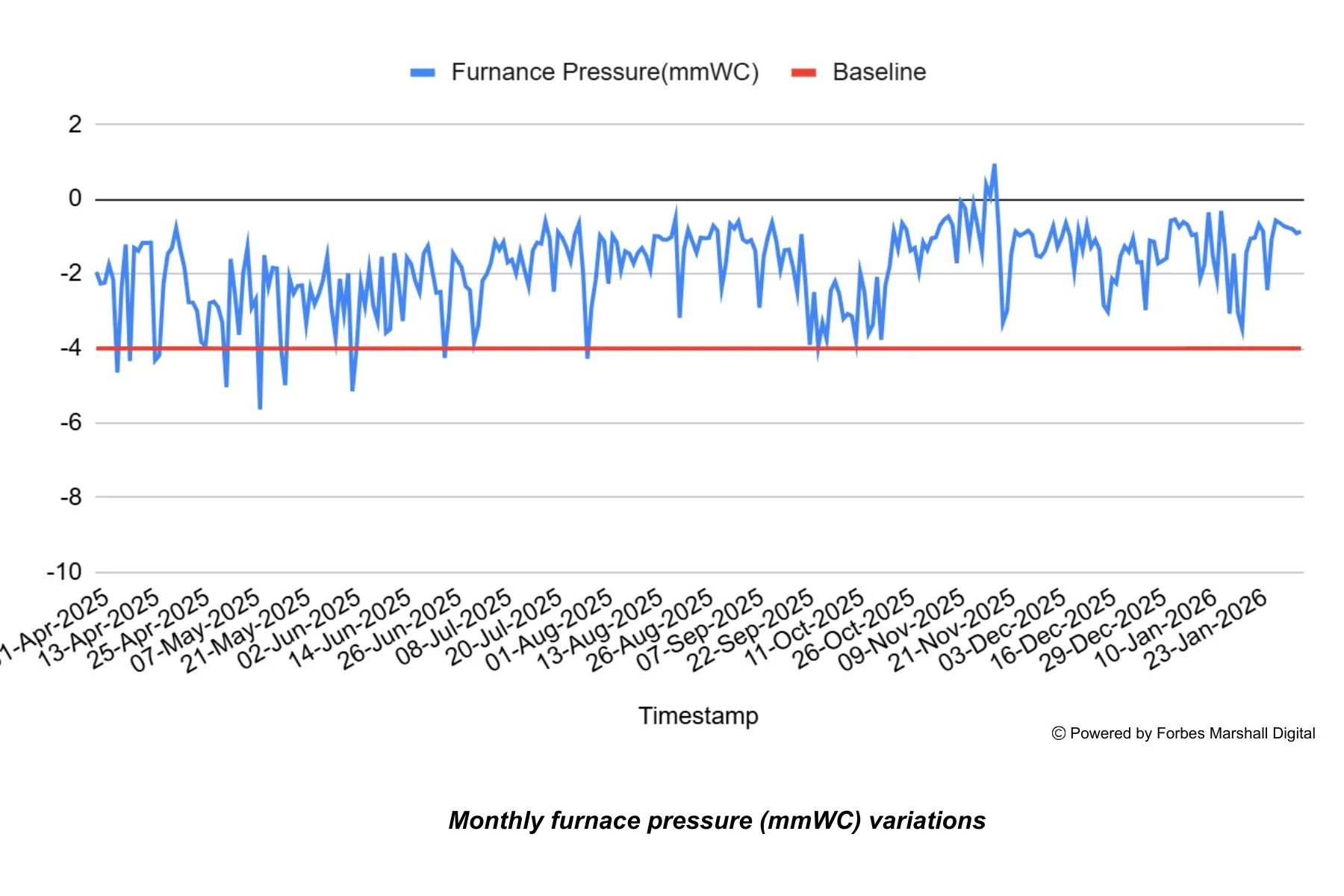

The furnace draft pressure was excessively high (-4 to -5 mmWC).

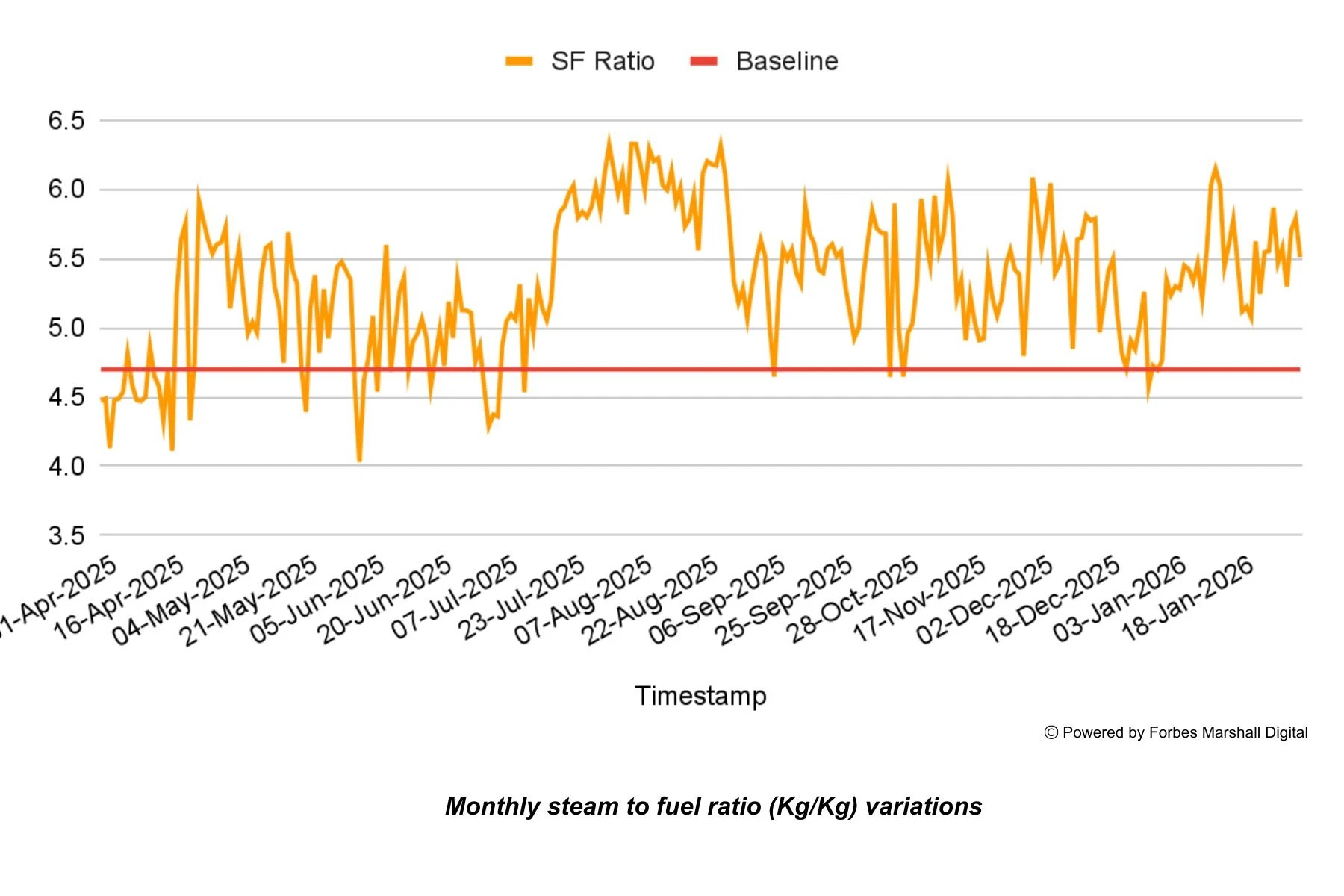

Steam to fuel (S:F) ratio was low at 4.7 Kilograms/Kilogram.

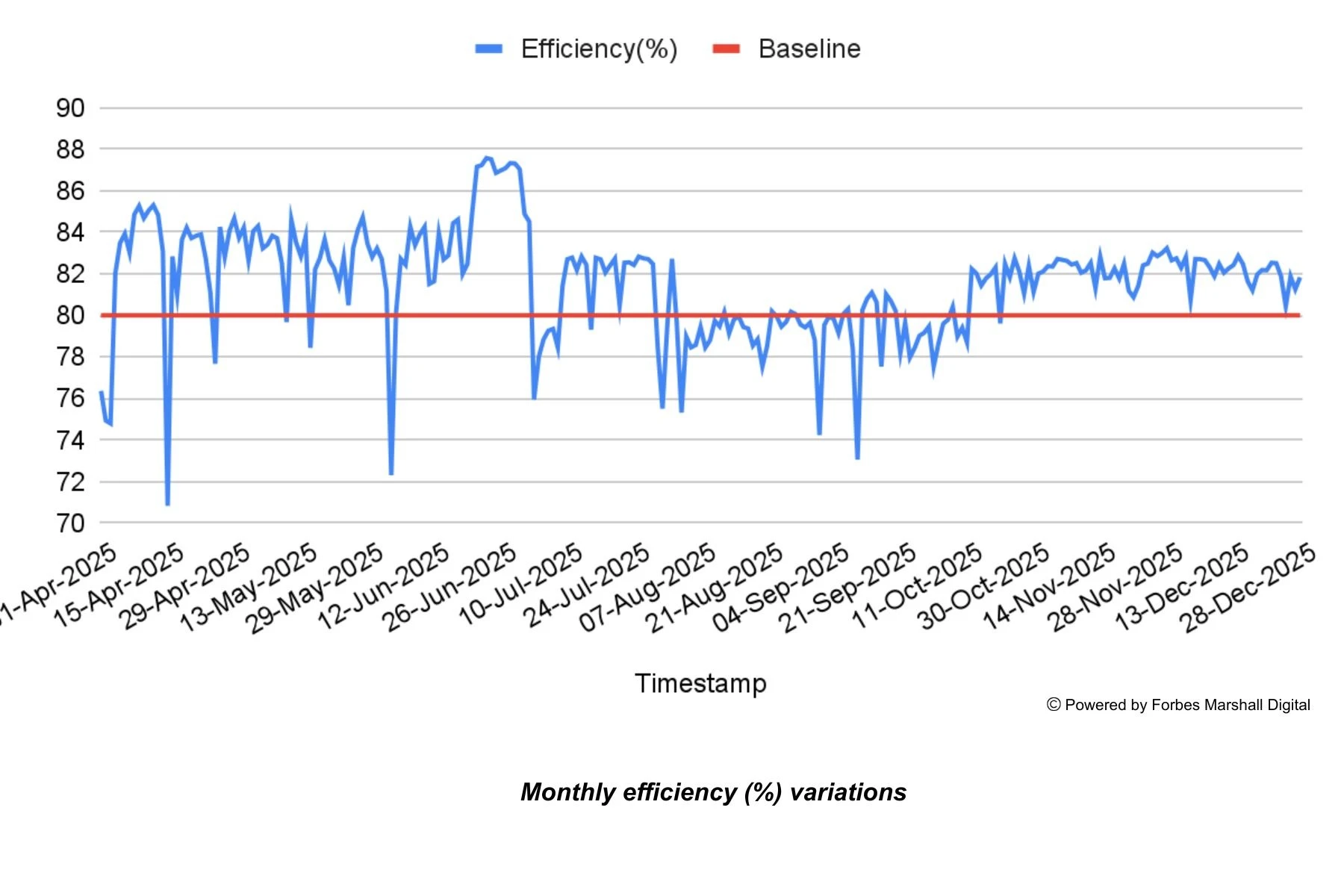

Boiler efficiency dropped to 80% due to inefficient combustion and heat losses.

Blowdown TDS was excessively high at 5868 ppm.

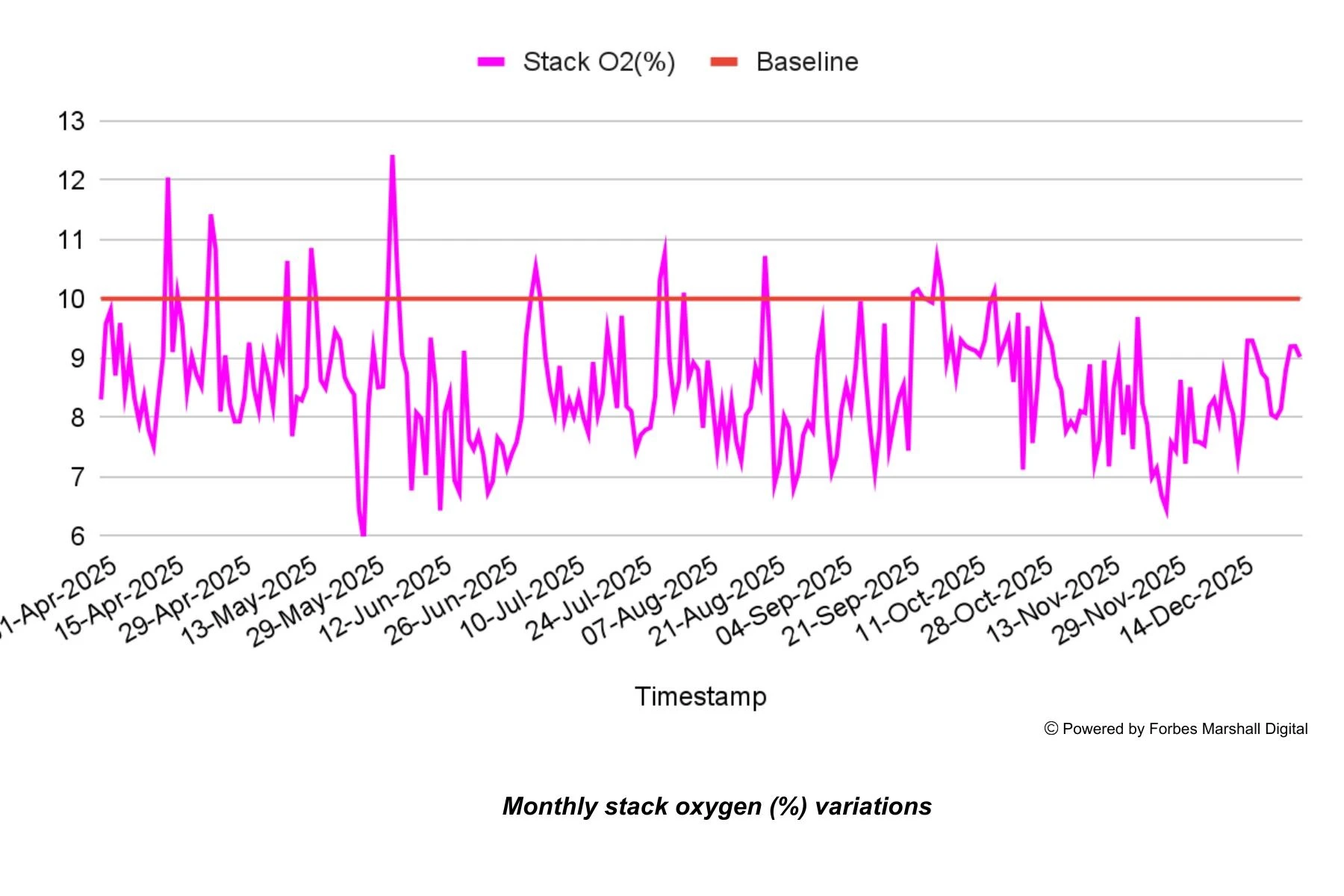

Stack O₂ levels remained high at 10-11%.

Backfiring was observed, attributed to high excess oxygen and unstable combustion conditions.

A backfire issue was observed,likely caused by high stack O₂ levels leading to unstable combustion.

SOLUTION

Forbes Marshall digitally connected relevant equipment, established P&ID drawings, and identified and mapped problem areas related to boiler efficiency and steam to fuel ratio across the plant.

Equipment uptime was improved and sustained at >90% through digital monitoring and data-driven insights, enabling timely corrective action.

Implemented automated boiler pressure control at 8.5 bar (8-9 bar band) by modulating feeder speed, reducing ON/OFF cycling from 5-8 times/hour to once every 30-60 minutes.

Optimised furnace draft control by maintaining -2 to -3 mmWC through automatic ID fan modulation, eliminating frequent backfire issues and stabilising combustion.

Introduced coordinated fuel-air control using a firing table control concept, synchronising FD fan speed with feeder speed to maintain optimal O₂ levels between 4-9%.

Reduced excess air and improved combustion efficiency through structured fan tuning with CSD support.

Initiated detailed inspection and root-cause analysis for inconsistent blowdown TDS control, with corrective action plan under evaluation.

BENEFITS

Boiler efficiency improved from 80% to 83%, achieving a 3.75% increase in efficiency.

Steam to fuel (S:F) ratio improved from 4.7 to 5.5 Kilograms/Kilogram, resulting in 17% fuel savings.

Stack O₂ reduced from 10.0%, achieving a 15% reduction in excess oxygen levels.

Fuel savings achieved through optimized O₂ control and burner fine-tuning, leading to improved combustion performance.

Reduced boiler on-off cycling, resulting in smoother operation and improved boiler life

Improved combustion stability, reducing backfire and operational risks

Optimised fuel and air coordination, leading to better efficiency

Stabilised oxygen levels, minimising excess air losses

Improved steam generation reliability, supporting consistent plant production

Foundation created for further efficiency improvement through TDS and blowdown optimisation

Products

Associated Services

Process Optimization

Improving Uptime

Forbes Marshal Digital

Associated Services

What to read next