Beverage to fuel ratio improved by 34% for a beverage MNC in Malaysia

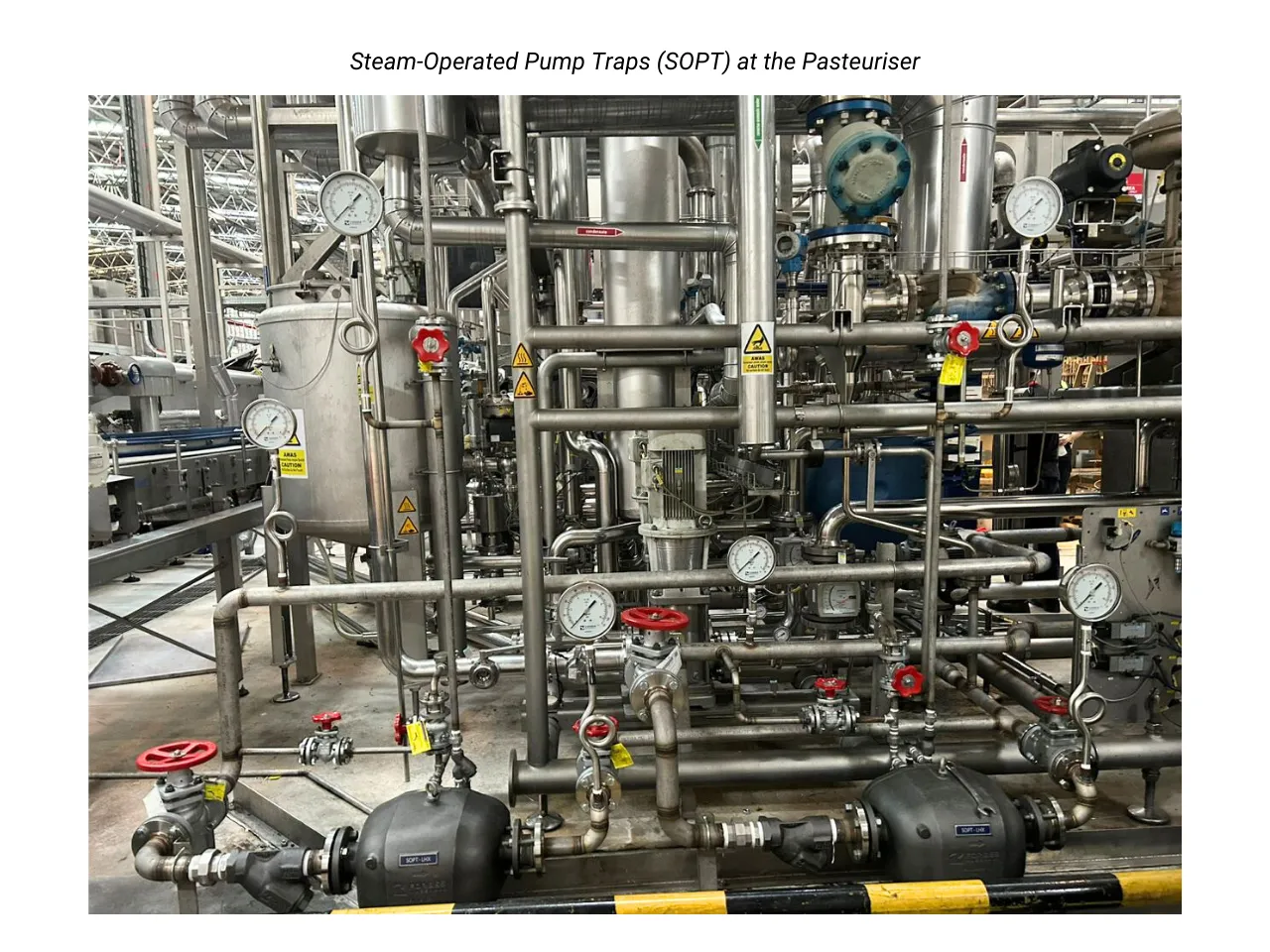

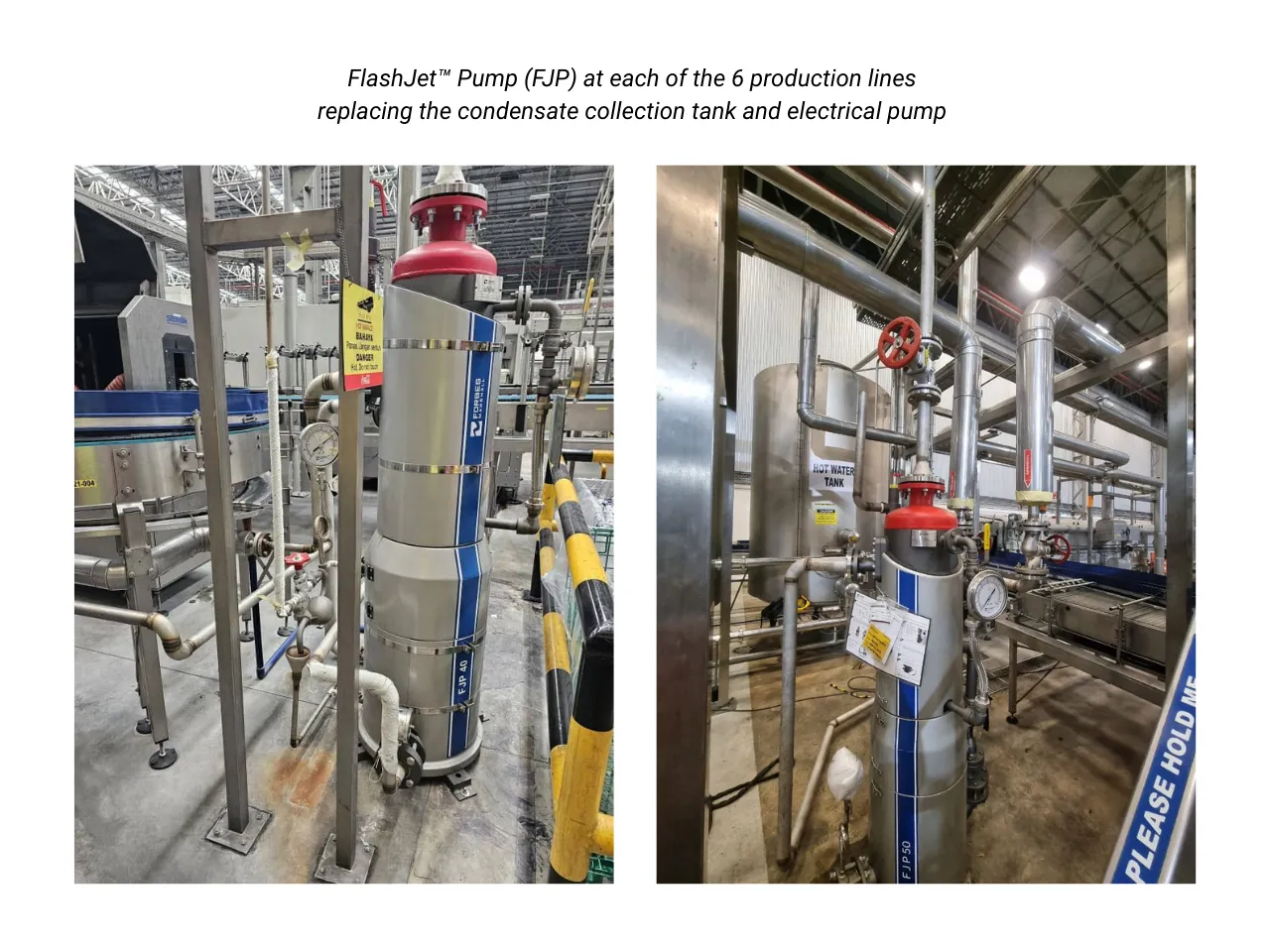

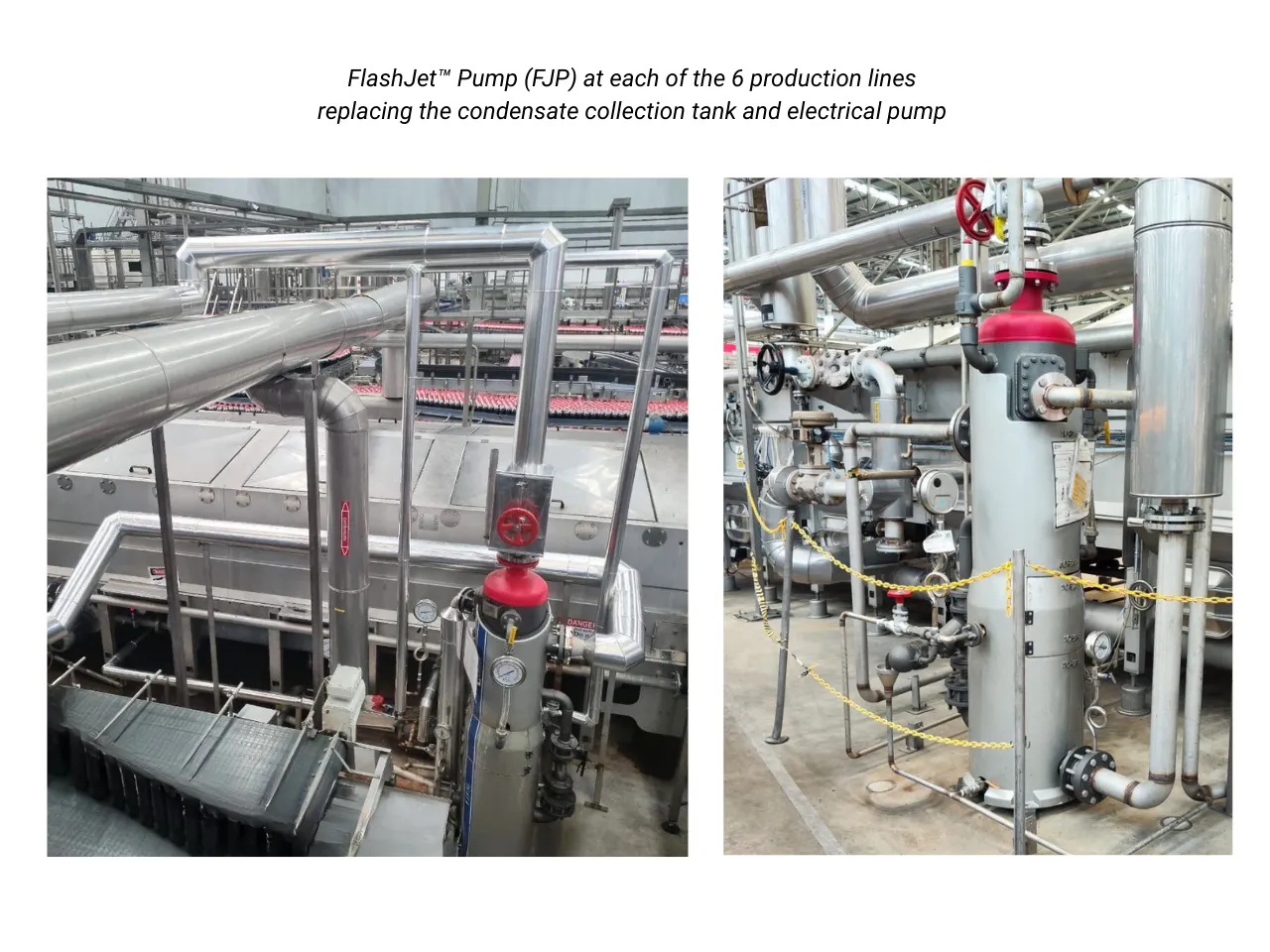

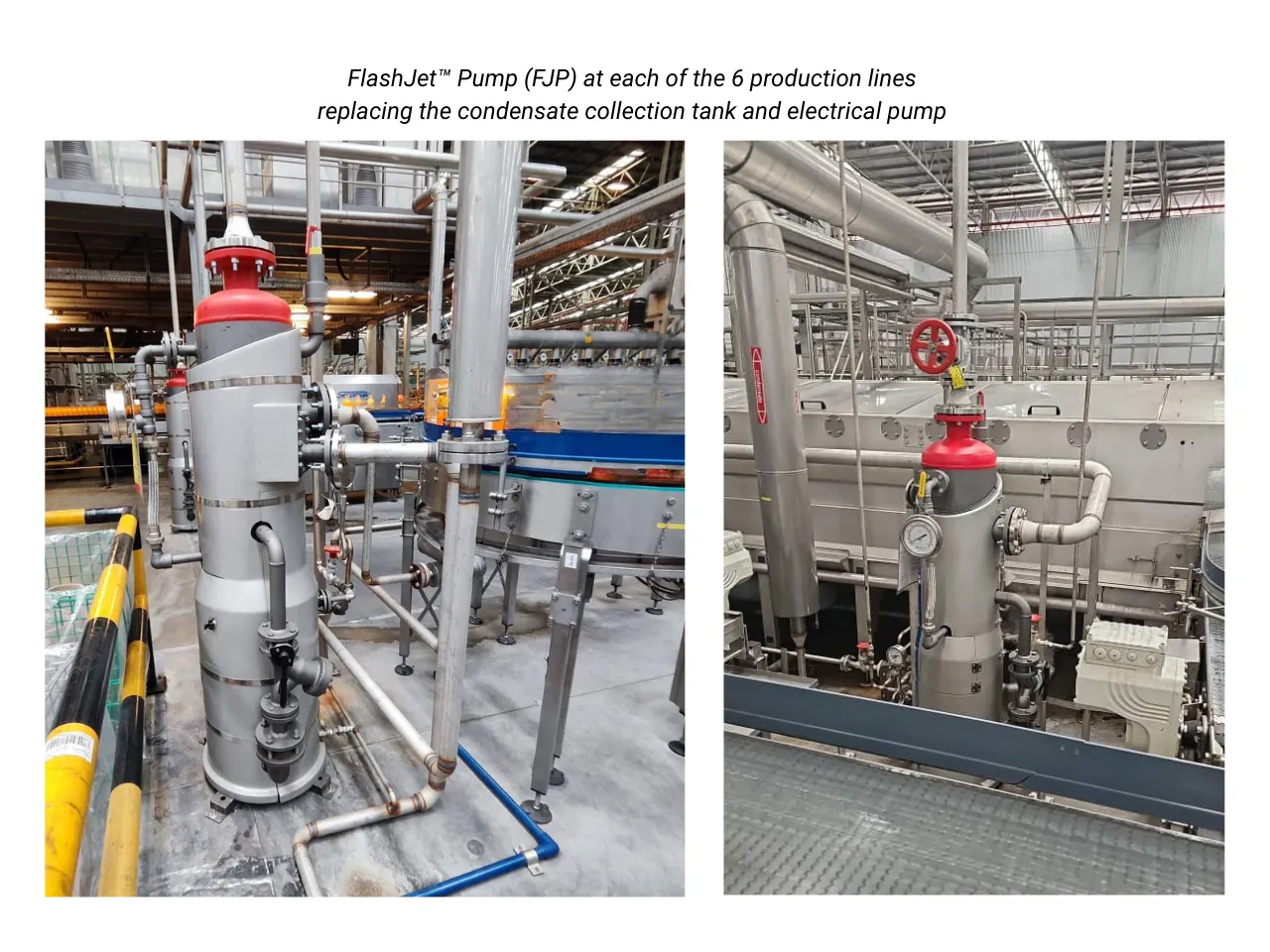

An aerated beverage MNC in Negeri Sembilan, Malaysia was facing several issues with its steam and condensate system. Six warmers were experiencing pressure and temperature fluctuations and were running at reduced RPM (revolutions per minute). The pasteuriser was facing temperature variations and reduced throughput. Condensate recovery factor was 55% and flash steam was being vented. Forbes Marshall conducted a plant study and recommended thermal energy conservation solutions to improve the steam and condensate system for 6 production lines.

Products

Associated Services

Process Optimization

Improving Uptime