Boiler efficiency improved by 40% for a chemical manufacturer in India using FM Digital

A chemical manufacturing plant in Gujarat, India was facing variations in its utility KPIs, impacting the overall production efficiency of the plant. Their partnership with Forbes Marshall Digital began in June 2025 with a shared objective of improving and sustaining boiler efficiency using EverSense for Boiler Efficiency, a Forbes Marshall Digital sustenance service.

PROBLEM

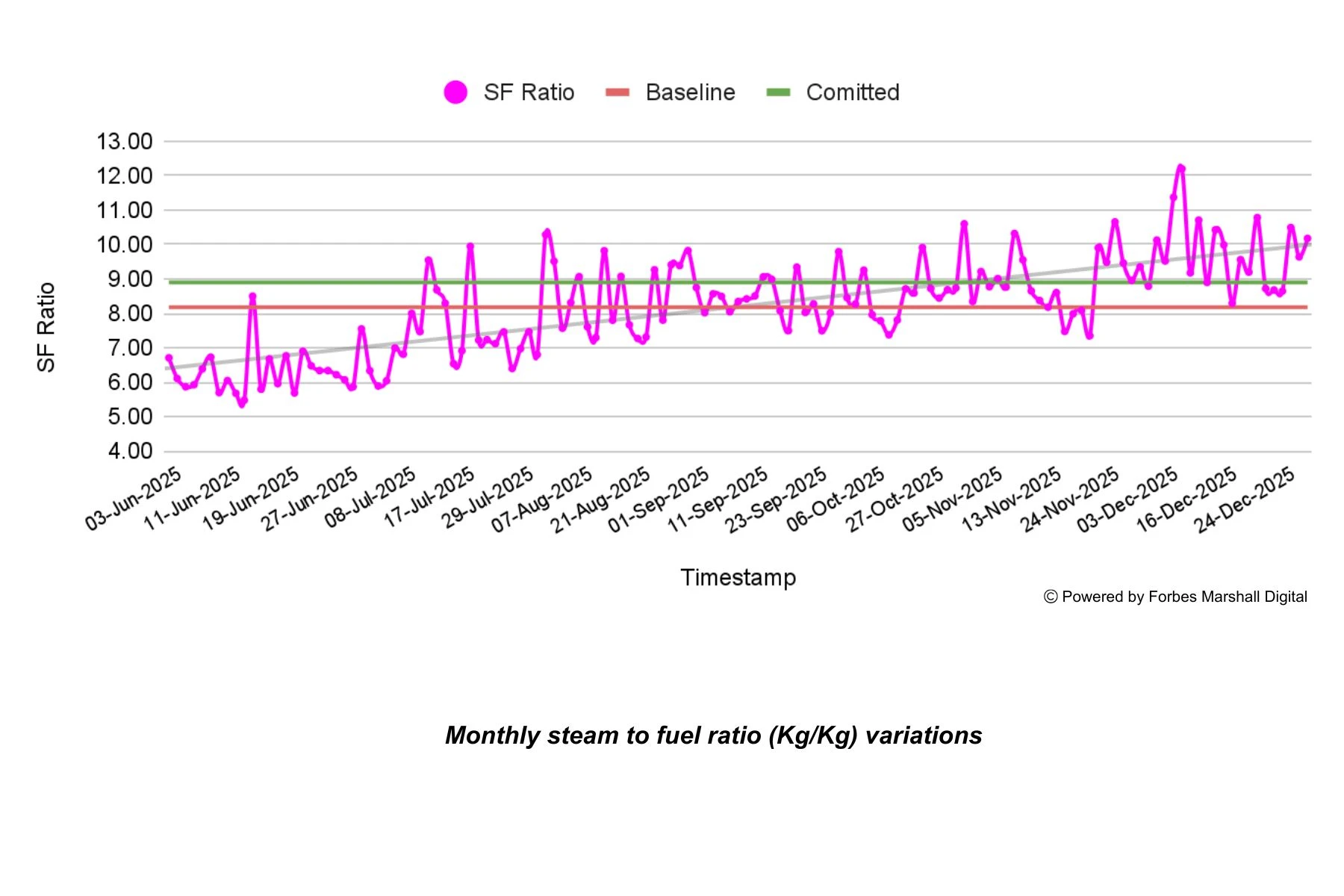

Boiler steam to fuel ratio (S:F) was 6.7 Kg/Kg (14.8 Pounds/Pound), significantly lower than the base value of 8.18 Kg/Kg (18 Pounds/Pound), indicating inefficient fuel utilisation.

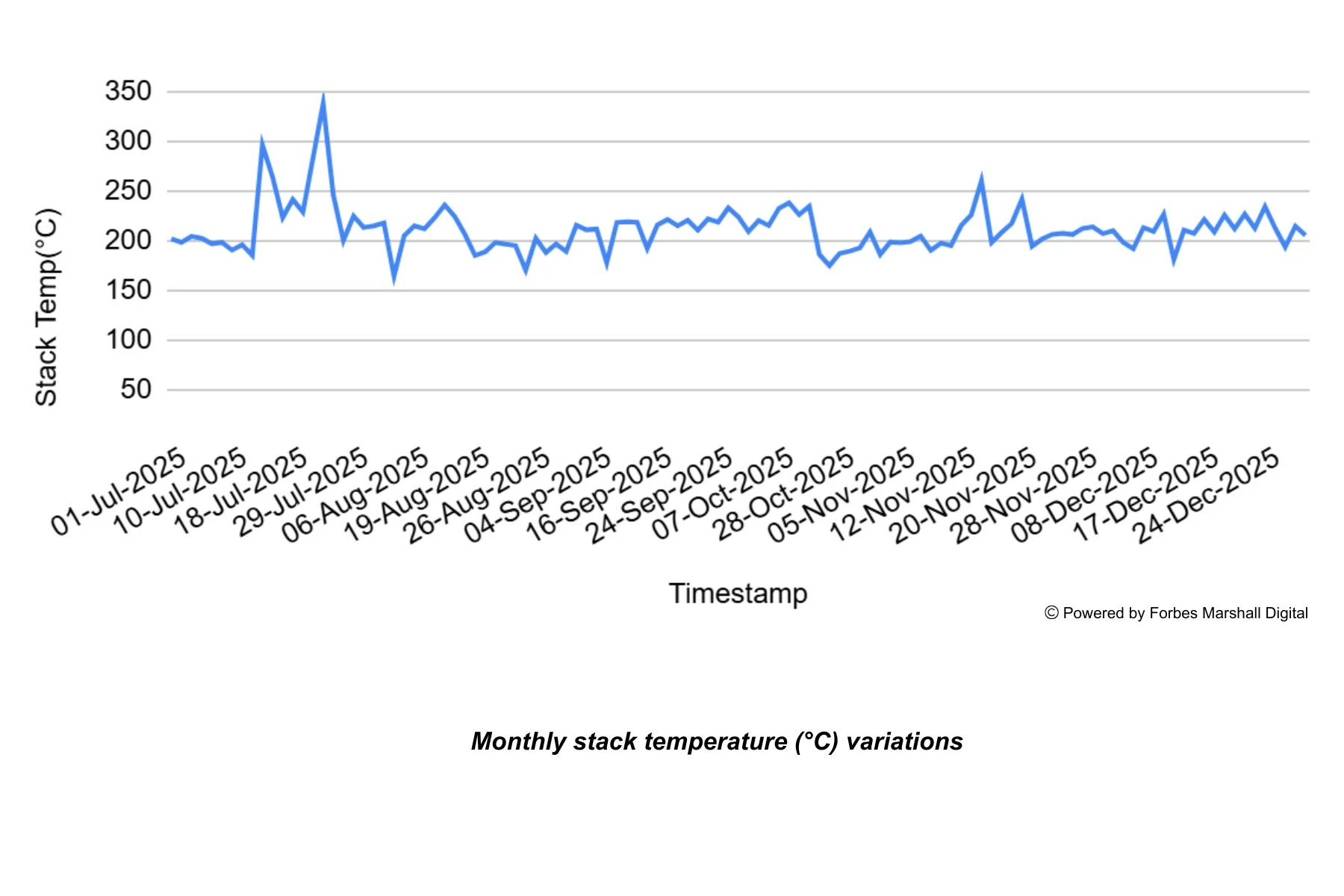

Stack temperature was 260°C (500°F), leading to high heat losses in the stack.

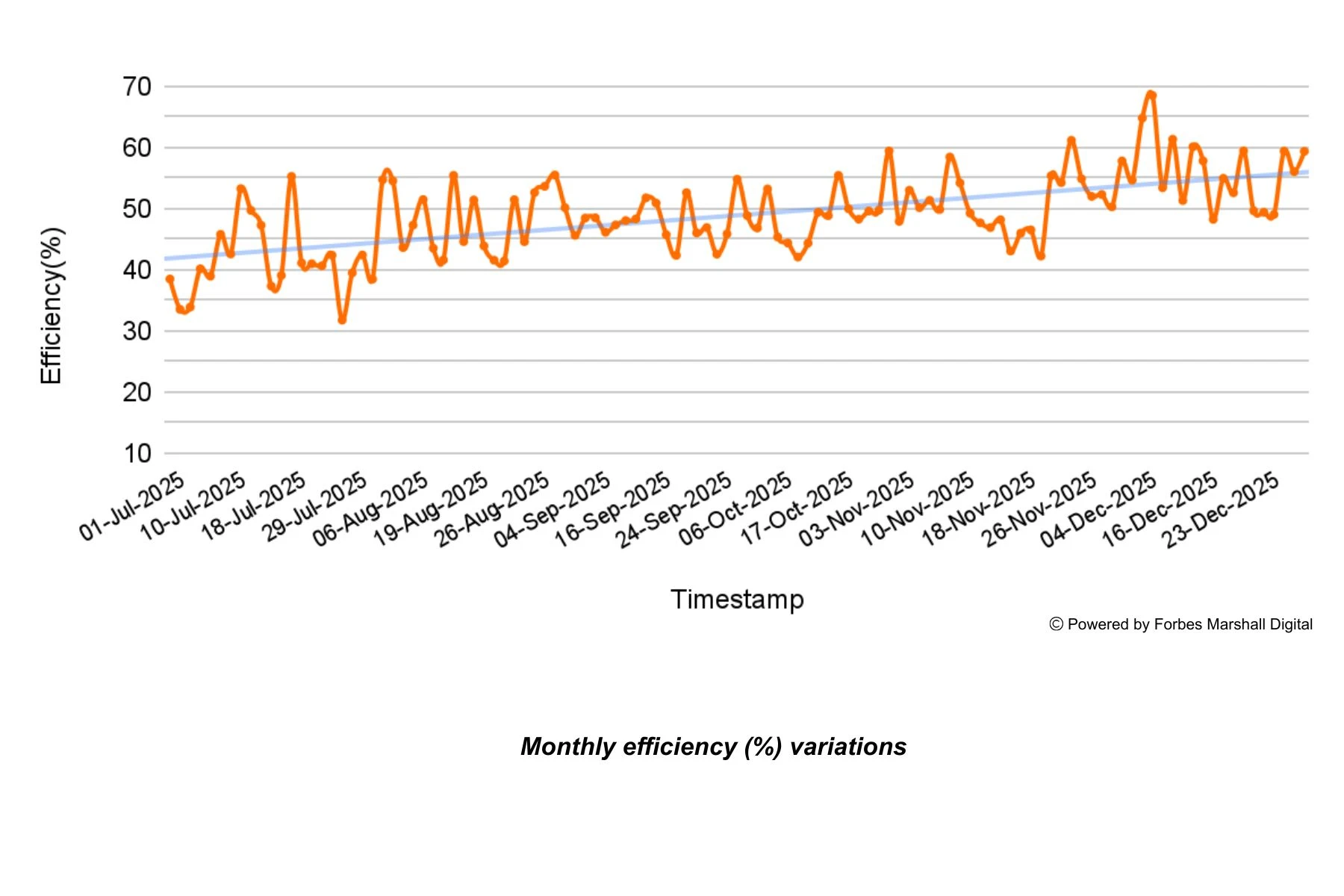

Boiler efficiency was significantly low at 40%, primarily due to poor combustion and excessive heat losses.

Drum TDS level was 3921 PPM, exceeding recommended limits, indicating inadequate blowdown control and higher energy losses.

SOLUTION

Using Forbes Marshall Digital solutions, we digitally connected critical boiler equipment to our EverSense platform. We improved and sustained equipment uptime at >90% through continuous digital monitoring and data-driven insights, enabling timely corrective action.

Conducted burner tuning at both high and low firing by adjusting damper settings to optimise combustion.

Completed boiler house uptime assessment and scorecard, resulting in partial improvement in combustion efficiency.

Post identification of inadequate LDO (Light Diesel Oil) pressure, the IPRV (Inlet Pressure Regulating Valve) was replaced. This increased oil pressure and improved fuel atomisation, resulting in enhanced combustion performance and increased the steam to fuel ratio (S:F).

Identified abnormal rise in stack temperature through digital monitoring and subsequent site inspection.

The stack O₂ and CO levels were found to be high and black smoke was observed at low firing, indicating combustion imbalance.

Corrected primary air plate orientation, cleaned the diffuser, and replaced/reoriented atomisers to optimise combustion parameters.

O₂ and CO levels were maintained within acceptable limits across firing conditions and stack temperature was maintained between 203-210°C (397.4 – 410 °F), ensuring efficient and stable boiler operation.

BENEFITS

Boiler efficiency improved from 40% to 56%, achieving a 40% increase in efficiency through optimised combustion.

Steam to fuel ratio (S:F) increased from 8.18 to 9.77 kg/kg (18 to 22 Pounds/Pound), achieving 19% fuel savings.

Stack temperature reduced from 226°C to 211°C (438.8 to 411.8 °F), achieving a 6.6% reduction in heat loss.

Products

Associated Services

Process Optimization

Improving Uptime

Forbes Marshal Digital

Associated Services

What to read next