Improving boiler efficiency from 80% to 84% for a textile manufacturer in India using FM Digital

A textile manufacturer in Maharashtra, India was experiencing variations in its utility KPIs, impacting the overall production efficiency of the plant. Their partnership with Forbes Marshall Digital began in May 2025 with a shared objective of improving and sustaining boiler efficiency using EverSense for Boiler Efficiency, a Forbes Marshall Digital sustenance service.

PROBLEM

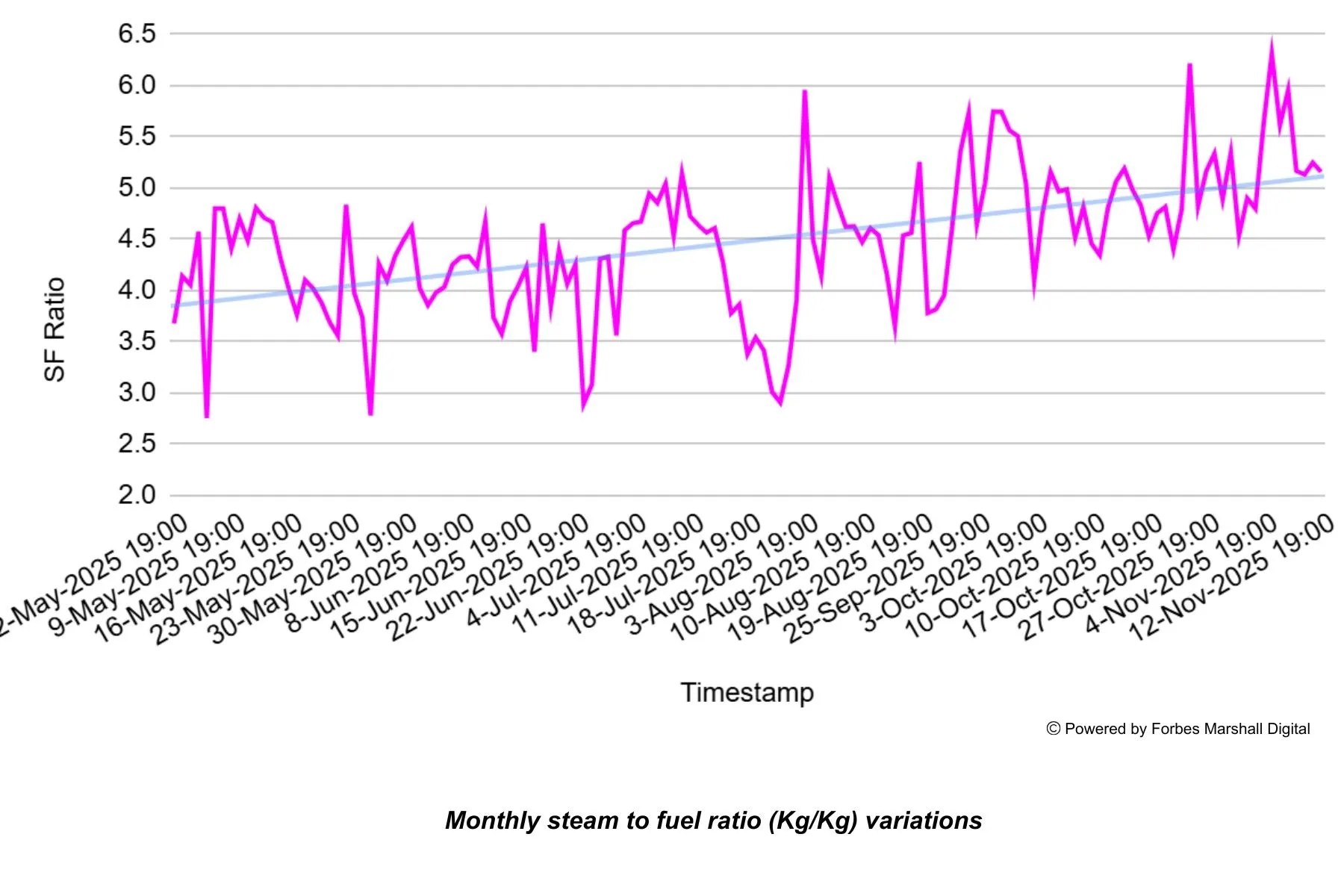

Boiler Steam to Fuel Ratio (S:F) was 4.2 Kg/Kg (9.3 Pounds/Pound), lower than the industry benchmark of 5.4 Kg/Kg (11.9 Pounds/Pound)

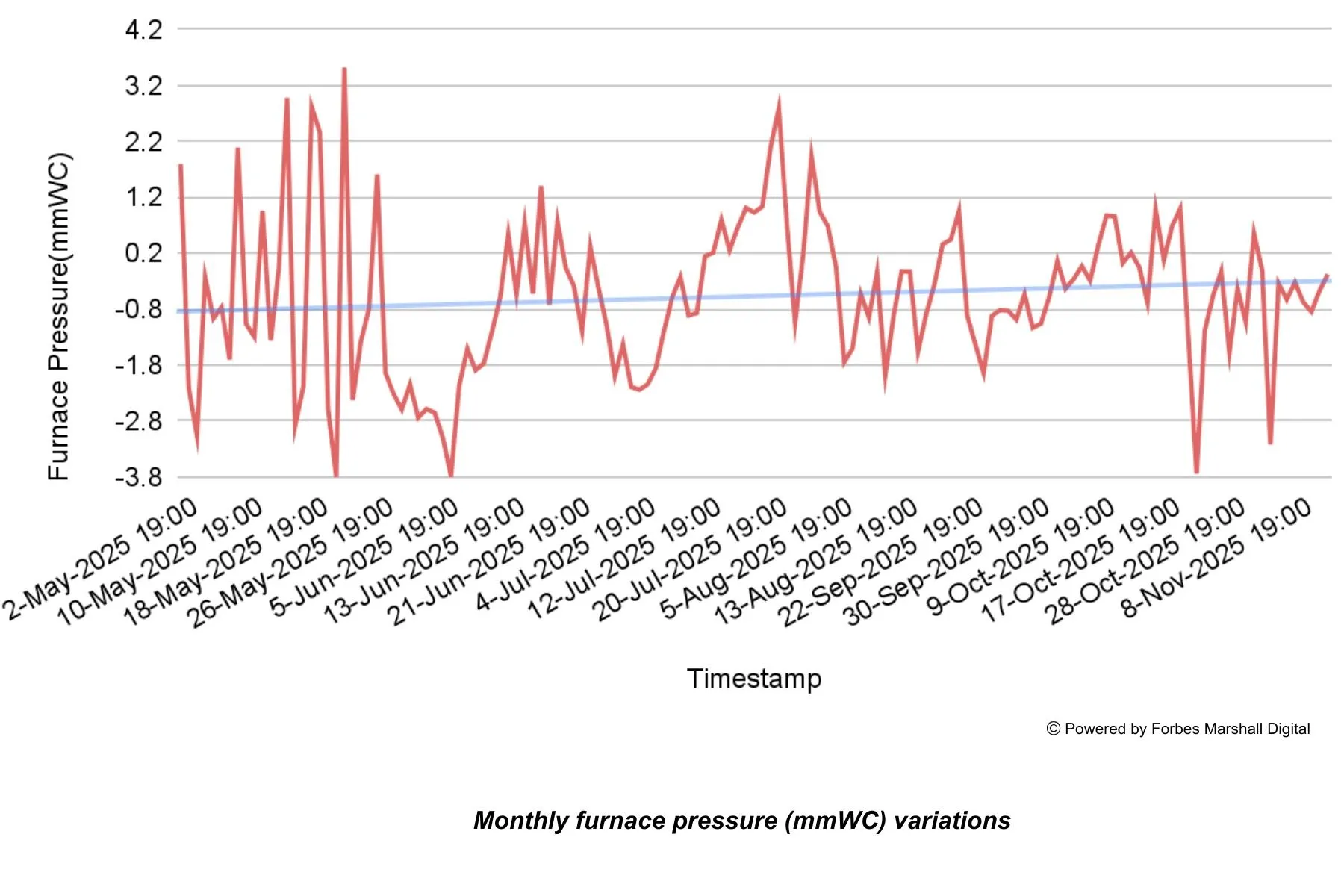

Positive furnace pressure was intermittently observed, indicating backfire issues

The boiler was operating at low steam loads

A steam flow meter malfunction led to interruptions in data recording and performance tracking

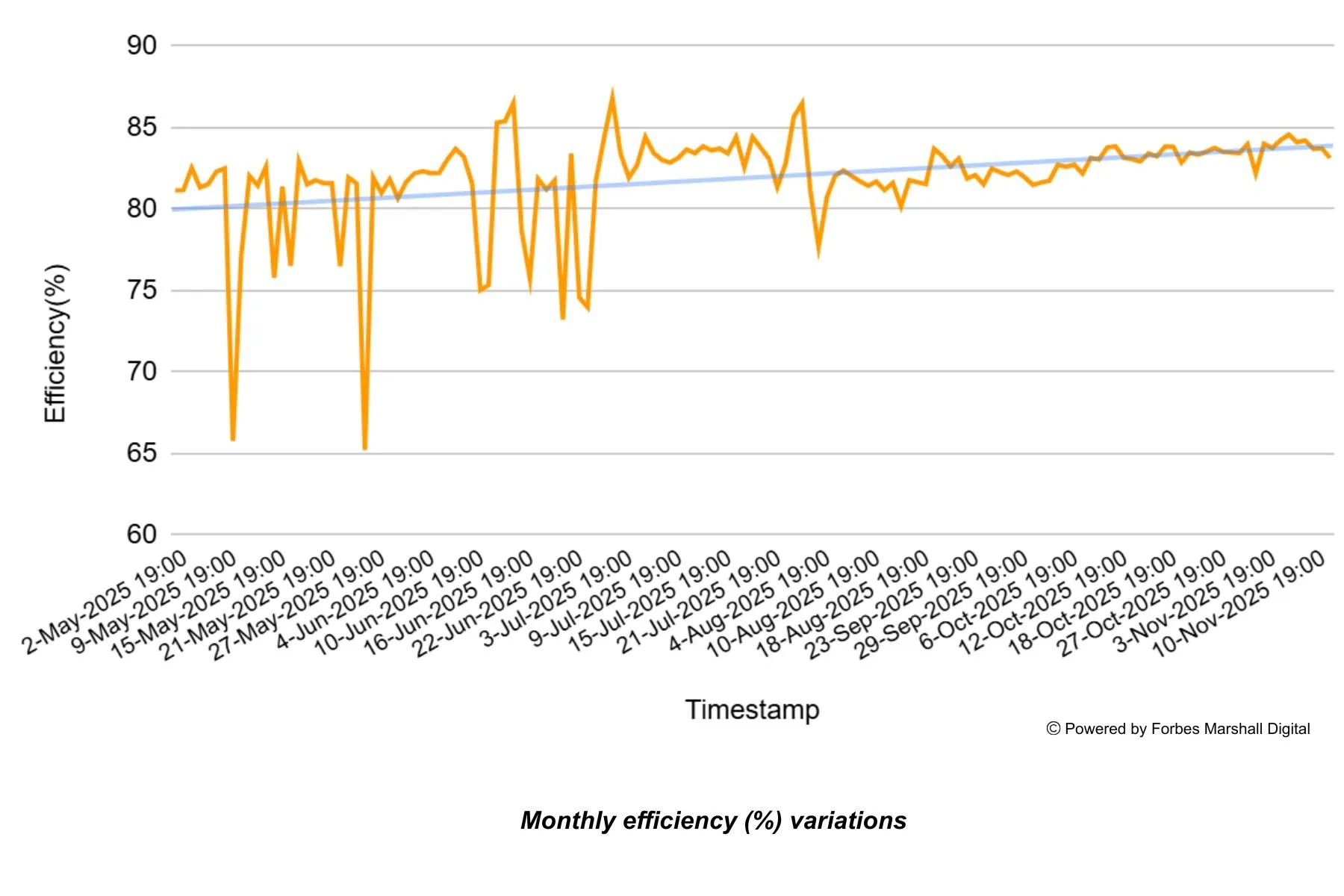

Boiler efficiency was recorded at 80%, compared to the benchmark efficiency of 84%

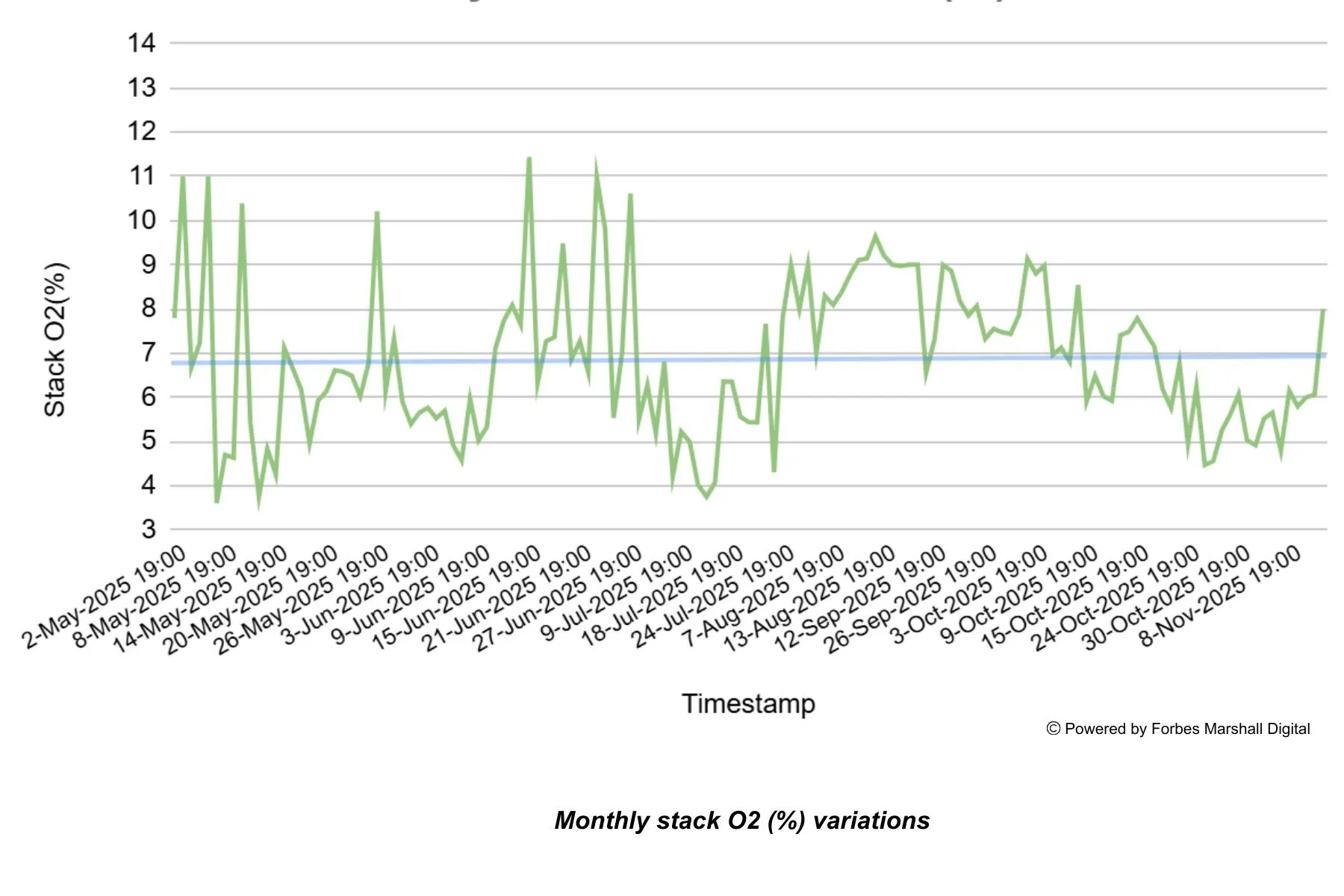

Stack oxygen (O₂) levels were high at 7%

SOLUTION

Forbes Marshall digitally connected all relevant boiler equipment, developed updated P&ID drawings, and identified efficiency and steam to fuel (S:F) loss points across the plant.

Improved and sustained critical equipment uptime at >90% through continuous digital monitoring and data-driven corrective action.

Identified positive furnace pressure through digital data analysis and recommended corrective actions, including ID Fan speed optimisation and verification of Differential Pressure Transmitter (DPT) calibration.

Calibrated the DPT to ensure accurate zero reading and cleaned the furnace pressure sensing lines to ensure reliable pressure measurement.

Conducted burner tuning and optimised ID fan operation, stabilising furnace pressure within the ideal range of -2 to -3 mmWC and eliminating backfire issues.

Optimised boiler steam load by recommending operation between 40-80% load and reducing steam pressure by 1 barg, resulting in improved boiler efficiency and S:F ratio.

Performed boiler combustion tuning to maintain optimal stack O₂ levels, leading to a measurable improvement in overall boiler efficiency.

BENEFITS

Increased boiler efficiency from 80% to 84%, achieving a 4% improvement in efficiency

Improved steam to fuel (S:F) ratio from 4.2 to 5.4 Kg/Kg (9.3 to 11.9 Pounds/Pound), achieving a 1.2% improvement. This resulted in fuel savings of 28.57%.

Reduced excess stack O₂ by 1%

Products

Associated Services

Process Optimization

Improving Uptime

Forbes Marshal Digital

Associated Services

What to read next