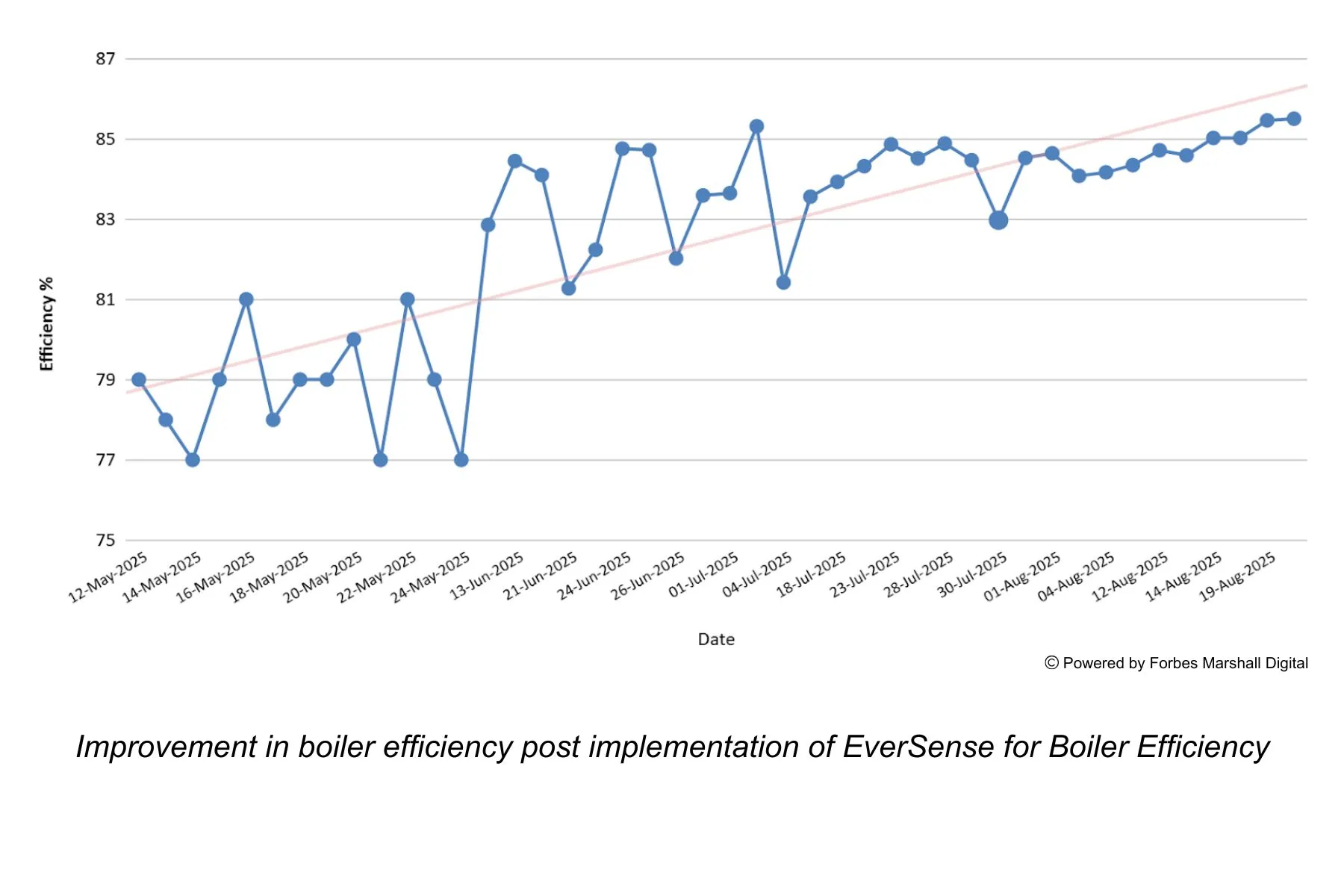

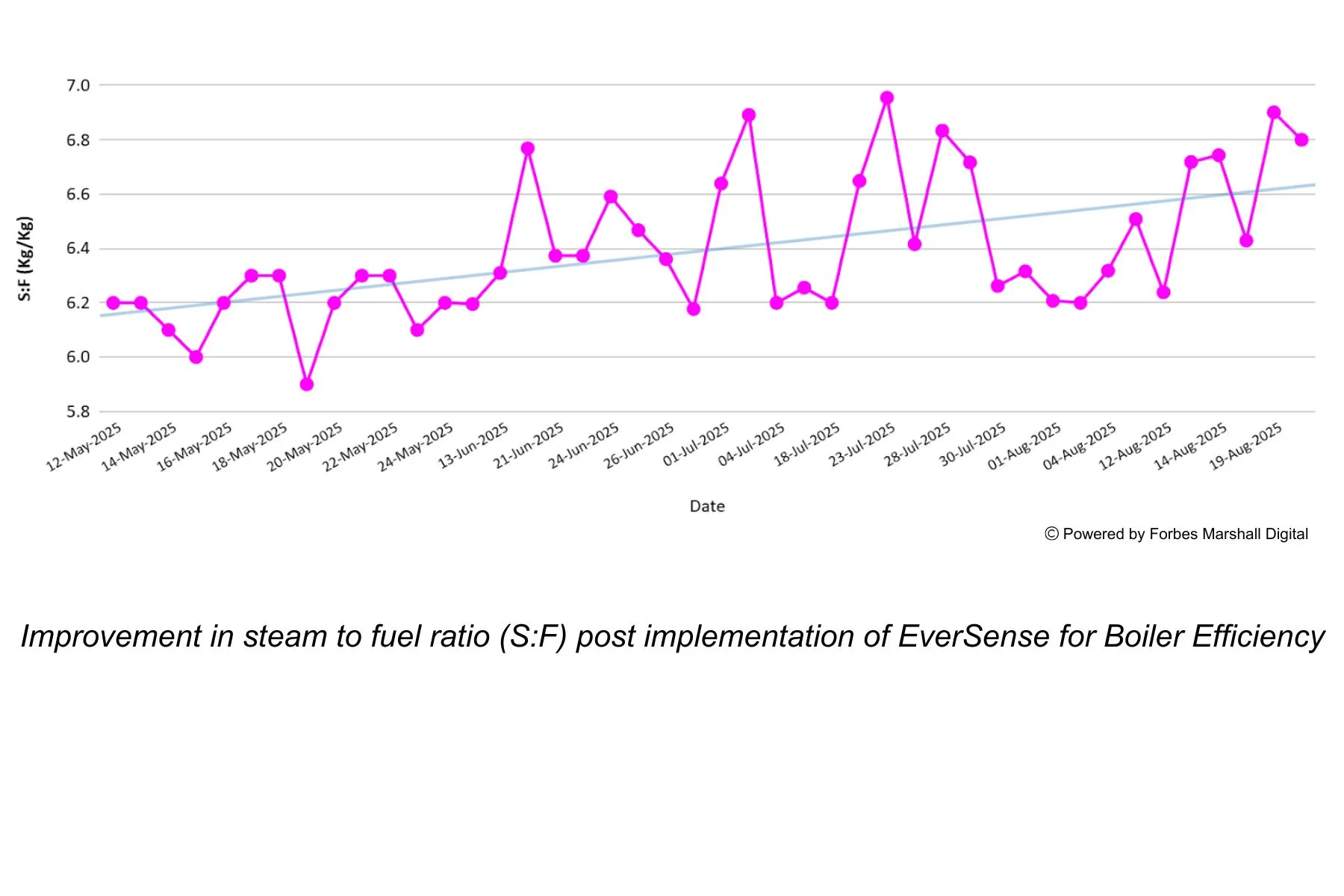

Improving boiler efficiency by 6.3% for a textile manufacturer using Forbes Marshall Digital

A textile manufacturer in Rajasthan, India faced a variation in their boiler efficiency, impacting productivity. Their ON/OFF cycles were 1.3 cycles/hr causing efficiency loss. They partnered with Forbes Marshall Digital in June 2025 with the shared goal of improving and sustaining boiler efficiency. EverSense for Boiler Efficiency helped load stabilisation and ON/OFF minimisation ensuring efficiency, improved feed water temperature and steam to fuel (S:F) ratio.

Products

Associated Services

Process Optimization

Improving Uptime