Increasing steam to fuel ratio by 3% for a pharmaceutical manufacturer in India using FM Digital

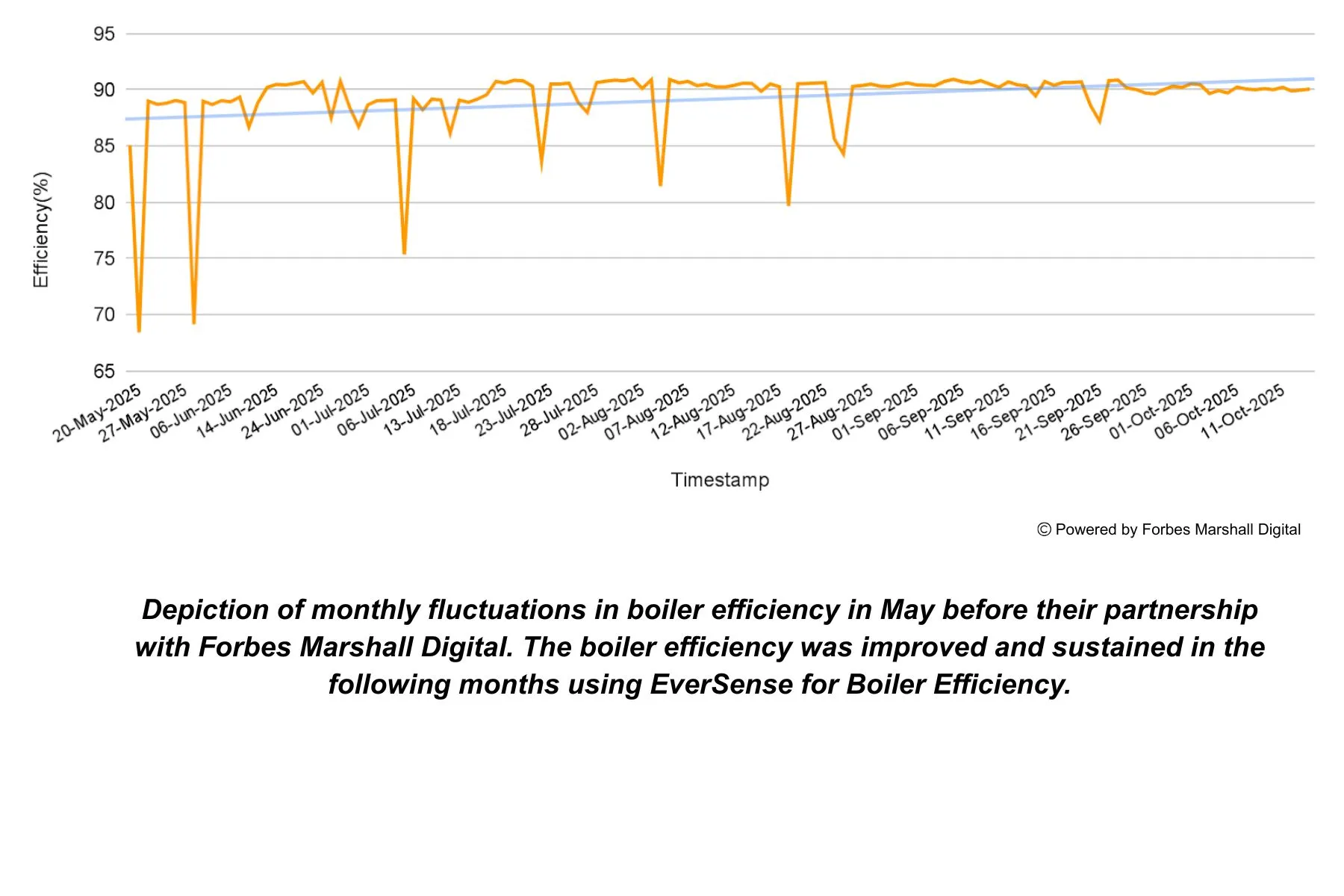

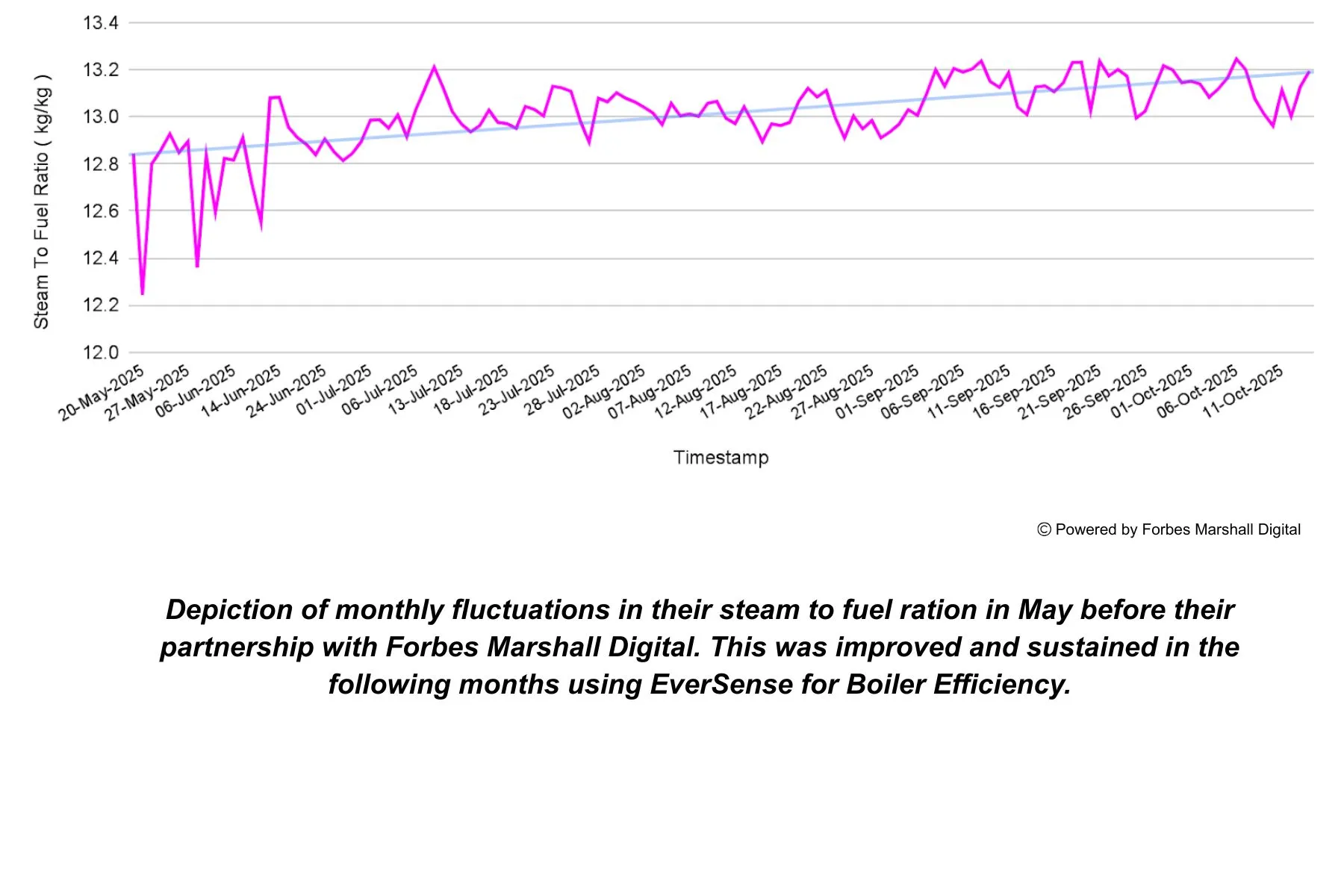

A pharmaceutical manufacturer in Telangana, India was facing variation in their utility KPIs, impacting their productivity. The partnership with Forbes Marshall Digital began in May 2025 with a shared objective of improving and sustaining their boiler performance using EverSense for Boiler Efficiency.

PROBLEM

Boiler steam to fuel ratio (S:F) was 12.8 kg/kg against the benchmark of 13.2 kg/kg.

Feedwater temperature was low, ranging between 62°C and 66°C.

Boiler efficiency was 88%, while the benchmark is 91%.

Feedwater tank level was not maintained at 6 Kilolitres.

Stack oxygen (O₂) was high at 3%, indicating combustion inefficiency.

The Effluent Treatment Plant (ETP) condensate is currently being drained due to contamination concerns.

Condensate from low-pressure equipment in the utility block is being drained. This was done as connecting it to the common condensate line leads to back pressure and stalling.

Mainline trap condensate near the pressure reducing station is being drained.

Kill tank condensate is also being drained, since installation of a condensate recovery pump is not feasible in the current setup.

SOLUTION

Using EverSense for Boiler Efficiency, their boiler was digitally connected and detailed P&ID drawings were made to identify problem areas affecting boiler efficiency and steam to fuel ratio.

- Equipment uptime improved and sustained at >90% through continuous digital monitoring and data-driven insights.

- A discussion with the customer revealed that 80% of condensate was being recovered while 20% was drained due to pump malfunction, possibly caused by contamination or back pressure in the condensate line.

- Leakages observed across the plant were flagged by EverSense and suggestions for rectification were implemented.

- Once these issues were resolved, condensate was redirected to the feedwater tank, increasing feedwater temperature to the optimal range of 80-85°C within 30 days.

- Optimisation of RO makeup water timing was recommended, reducing refill frequency from 2 hours to 1 hour. This adjustment ensures consistent maintenance of the makeup water tank level, improving system reliability and efficiency.

Future Plans:

- Provide a separate routing line for low-pressure condensate to enable efficient recovery.

- Plan for recovery of the mainline condensate to minimise losses and improve overall efficiency.

- Construct a pit and install a condensate pump within it to facilitate smooth and continuous condensate recovery.

- Conduct pH and TDS testing of the ETP condensate, and if results are within acceptable limits, plan for its recovery.

BENEFITS

Steam to fuel ratio increased from 12.8 kg/kg to 13.2 kg/kg, enhancing overall system performance.

Fuel savings of 3% achieved through O₂ reduction and burner fine-tuning.

20% of condensate recovered and returned to the feed water tank after addressing contamination and back-pressure issues.

Condensate line leakages were repaired, resulting in a feed water temperature increase from 80°C to 85°C.

Boiler efficiency improved from 88% to 91.4%, strengthening process reliability and energy utilisation, reducing fuel consumption.

Associated Services

Process Optimization

Improving Uptime

Forbes Marshal Digital

Associated Services

What to read next