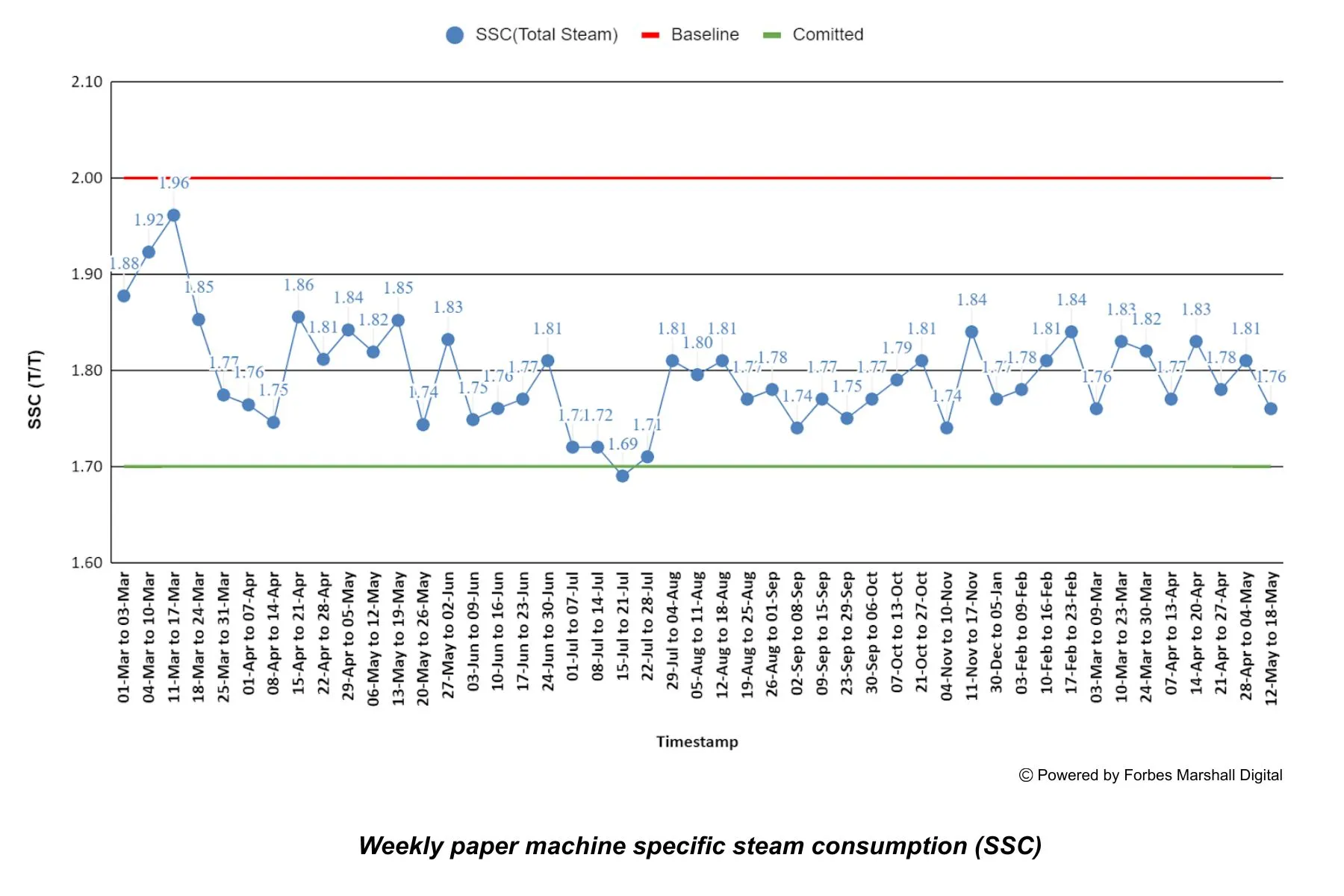

Improving specific steam consumption from 2.1-2.2 Kg/Kg to 1.8-1.9 Kg/Kg for a paper manufacturer in India using FM Digital

A paper manufacturer in Uttar Pradesh, India was experiencing variations in the specific steam consumption (SSC), affecting energy performance and overall production efficiency of the plant. Their partnership with Forbes Marshall Digital began in March 2024 with a shared objective of improving and sustaining SSC and condensate recovery factor (CRF) across the plant using EverSense for Paper Machines, a Forbes Marshall Digital sustenance service.

Products

Associated Services

Process Optimization

Improving Uptime