Decreasing chemical consumption by 30% and sludge generation by 20% for an automobile manufacturer in India using FM Digital

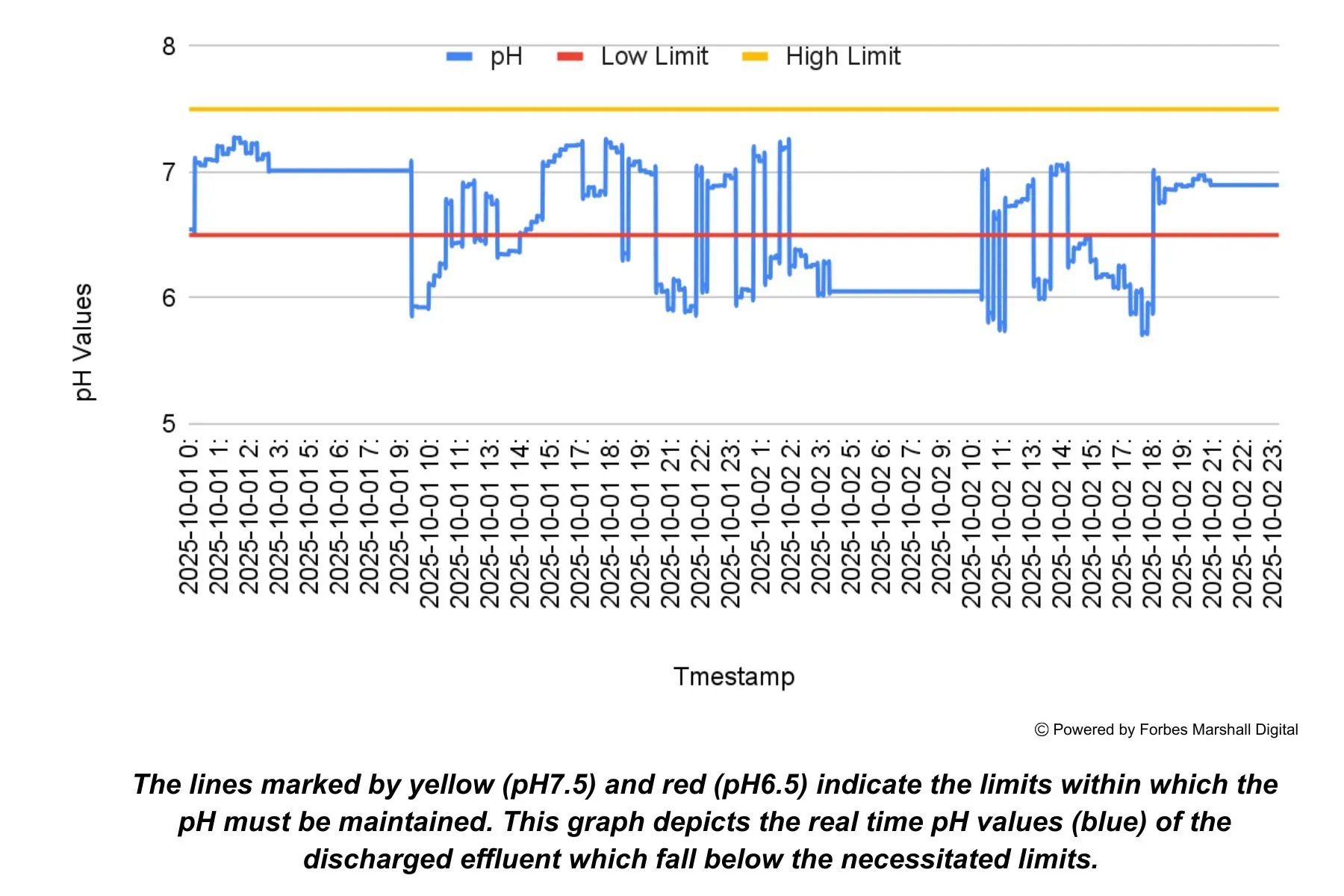

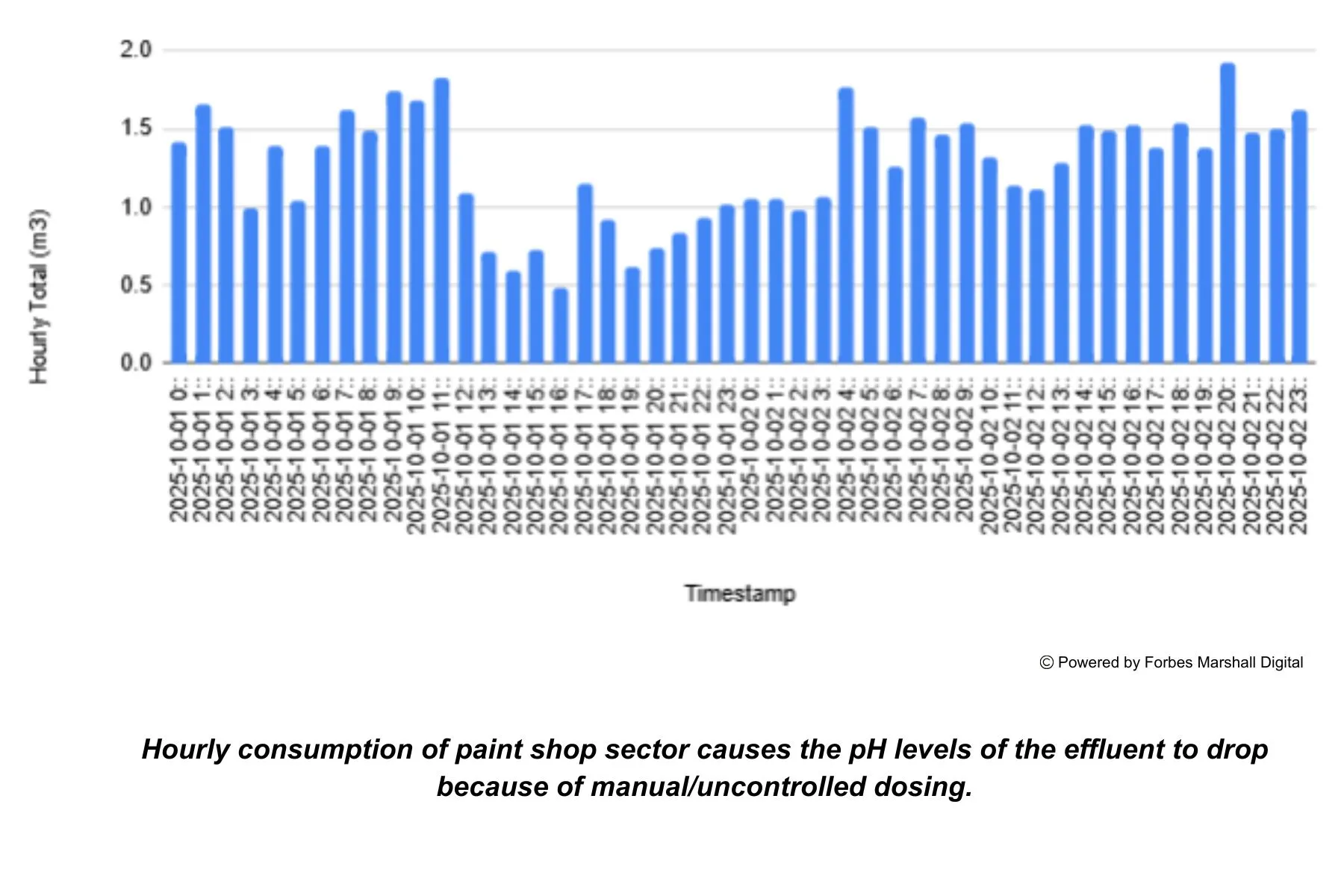

A prominent automobile manufacturer in Uttarakhand, India was facing challenges in the discharge of the acidic effluent generated through the manual alkali dosing at the paint shop. Maintaining consistent pH levels during discharge was difficult as:

- the manual alkali dosing process resulted in dosing errors,

- and/or basis the plant load,

increasing operational costs. The acidic effluent generated through this requires a precise pH correction before discharge from the Effluent Treatment Plant (ETP).

Their partnership with Forbes Marshall Digital began in February 2025 with the implementation of 2 services: EverSense for WaterMAP and EverSense for Water Validation and Utility System (WaterVU). This includes monitoring ETP outlet parameters, plant level water balance and freshwater consumption levels.

Products

Associated Services

Process Optimization

Improving Uptime