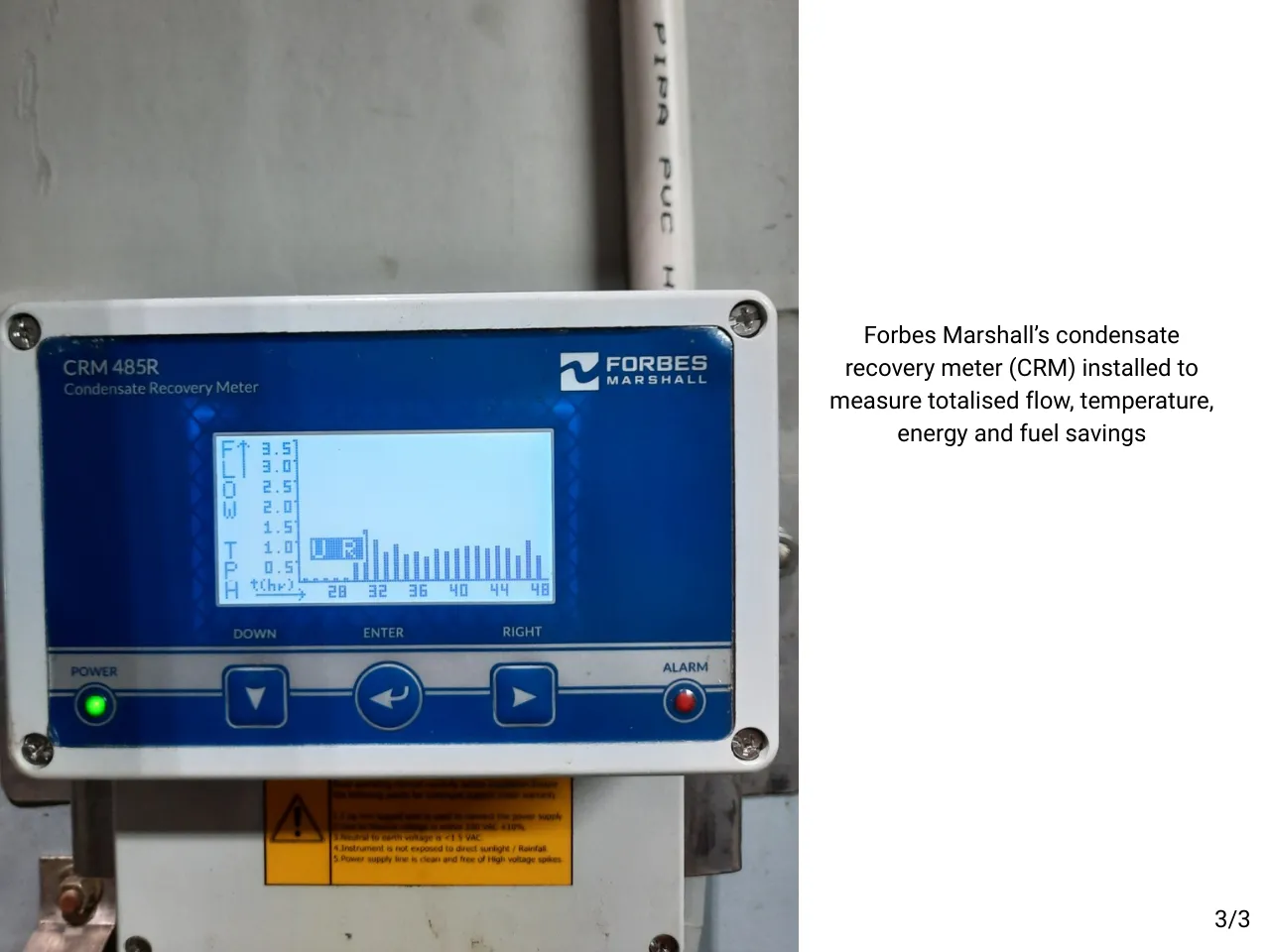

4.4% fuel and 88% makeup water daily savings for a beverage MNC in Indonesia

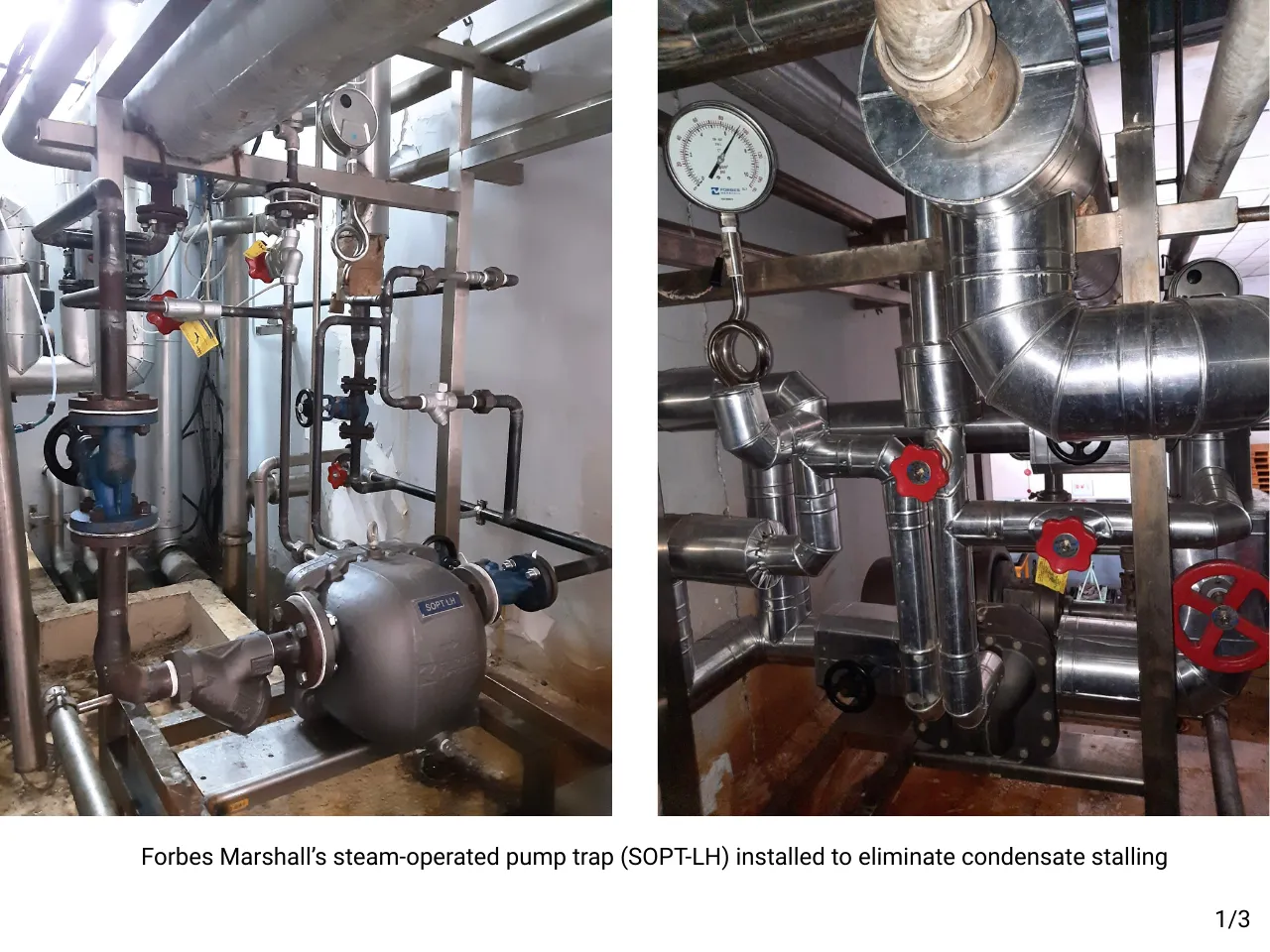

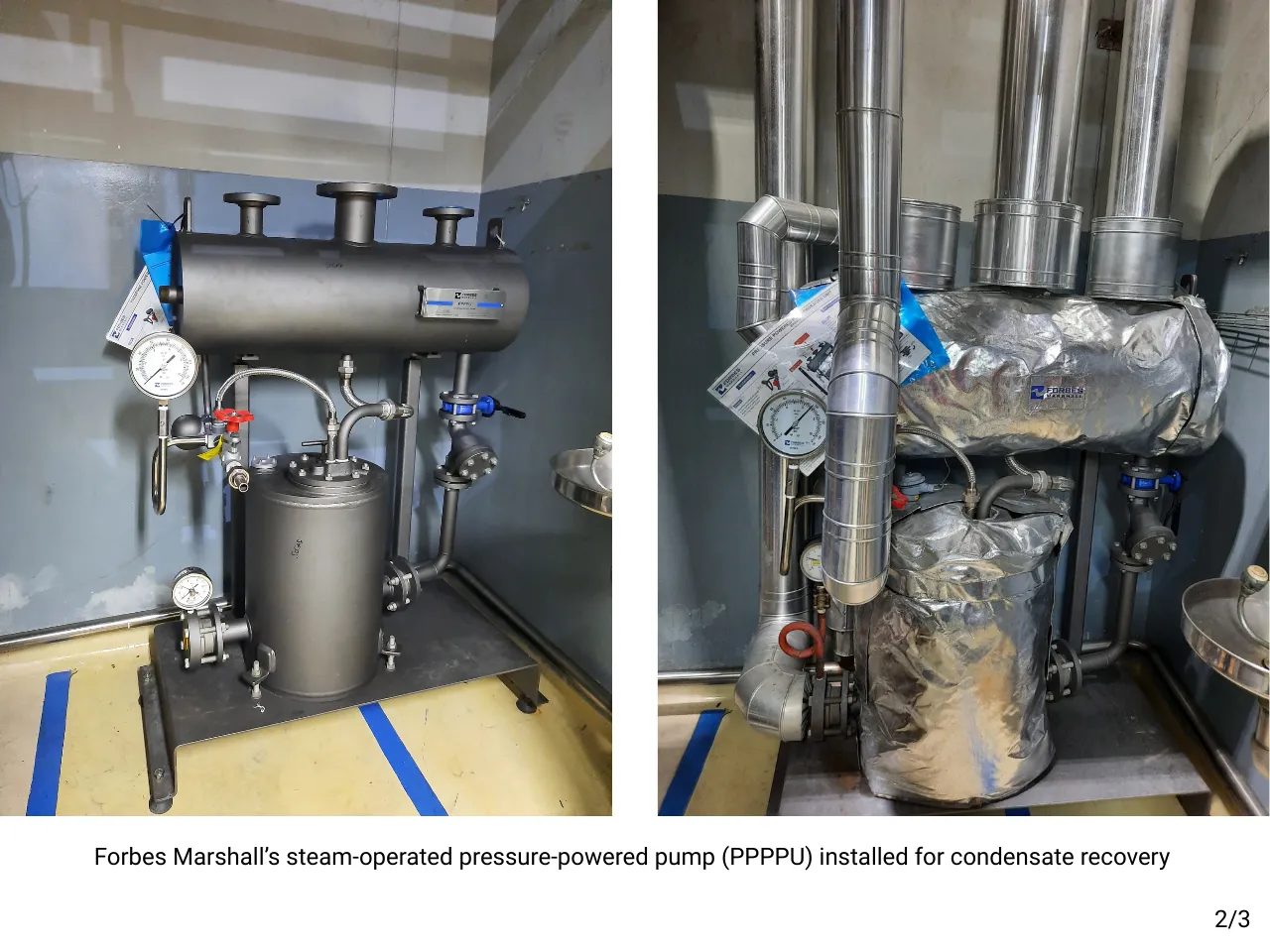

A beverage MNC in Western Java, Indonesia was facing issues with recovering condensate from their hot water generator (HWG) and clean-in-place (CIP) system. At 23%, the condensate recovery factor was very low indicating significant loss of heat energy. Forbes Marshall recommended and implemented thermal energy conservation solutions in the plant.

Products

Associated Services

Process Optimization

Improving Uptime