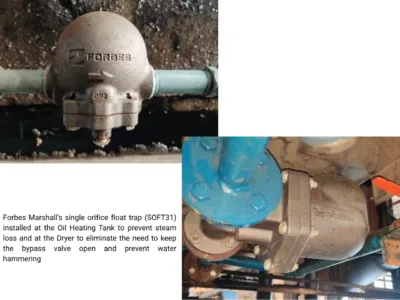

0.17 Tonnes fuel saved daily through steam trap system improvement for a fishmeal manufacturer in Thailand

A fishmeal manufacturing plant in Samut Sakhon, Thailand, faced issues in its steam system such as leaking traps, waterlogged traps, etc. Forbes Marshall conducted a plant study and recommended energy conservation solutions to improve the steam trap system.

Products

Associated Services

Process Optimization

Improving Uptime