USD 105,000 saved annually through steam system improvements for a ready to eat snack manufacturer in Thailand

A leading manufacturer of tomato-flavored snacks and instant noodles in Thailand faced issues in their steam trap layout for the dyer, oil heater and steamer. Forbes Marshall did an energy conservation survey and recommended solutions for improving the steam system.

PROBLEM

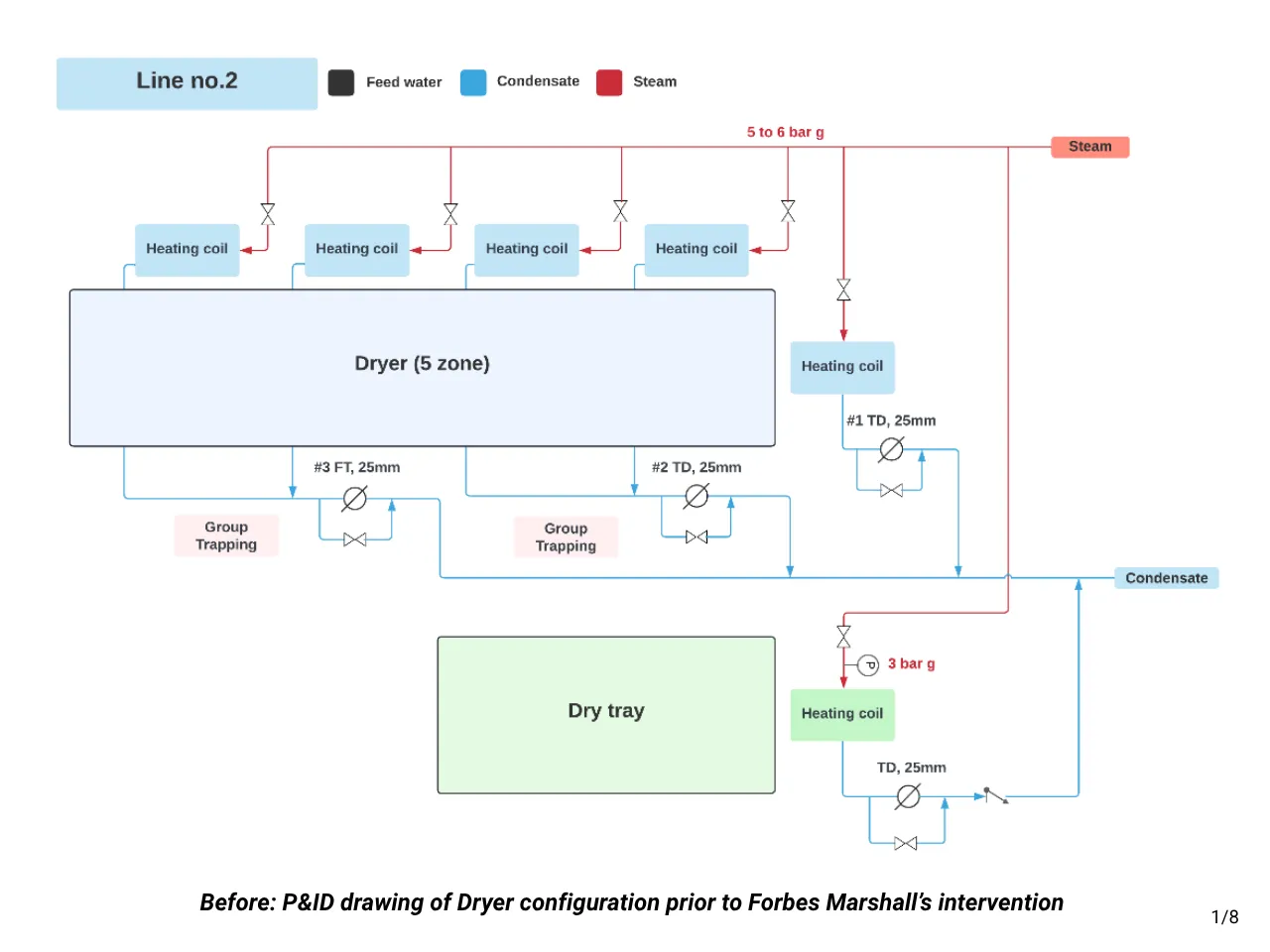

Dyers (System sketch available in the photos) :

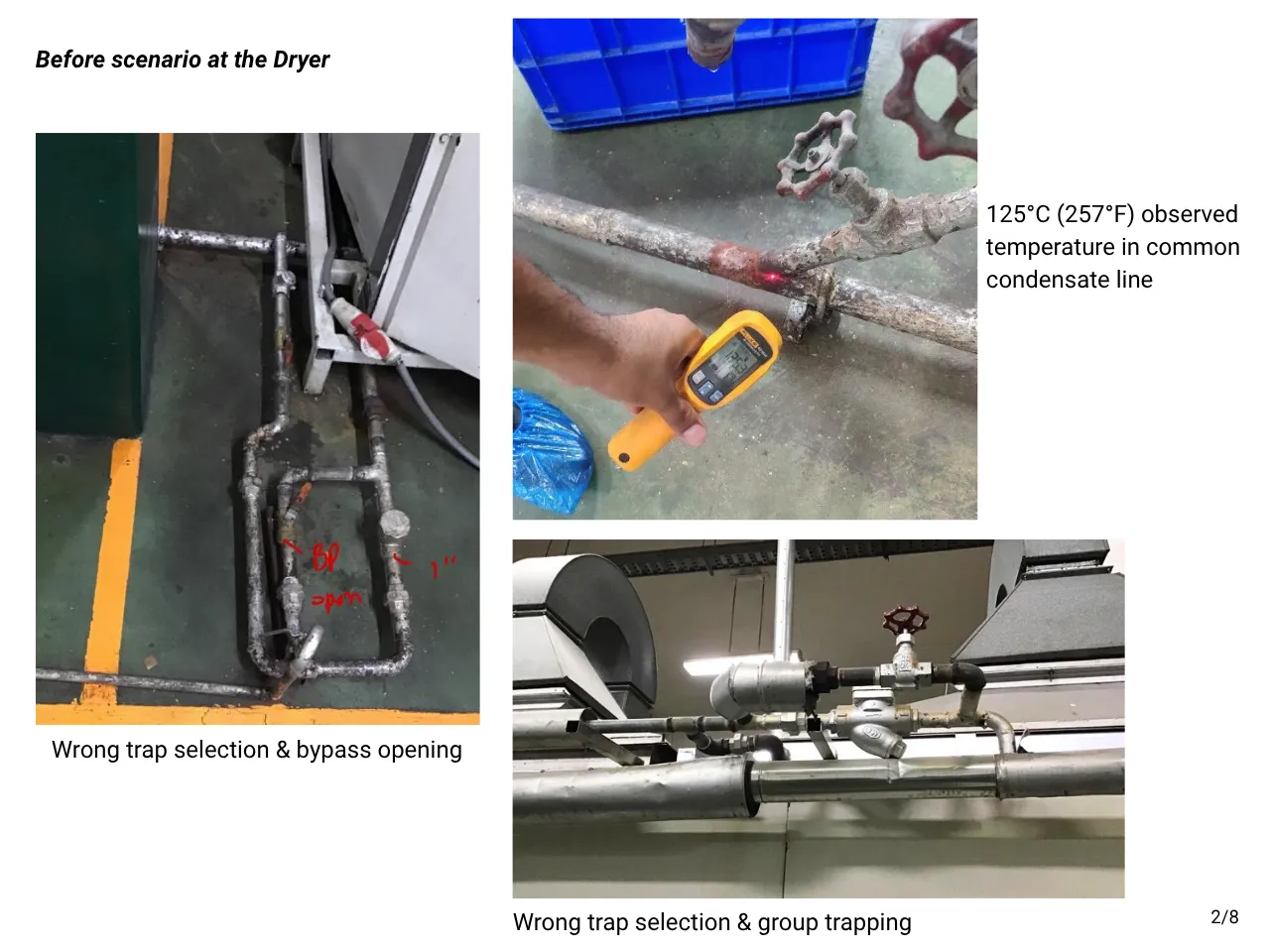

- The tray dryer was unable to achieve the set point temperature without opening the bypass valve of the thermodynamic trap (wrong steam trap for this purpose).

- The 5 zone dryer had group trapping, two thermodynamic traps and one float trap. This resulted in coil leakage (3 times a week) and loss of steam along due to thermodynamic trap bypass opening.

Fryer:

- A single float trap was installed for two oil heating coils (group trapping), leading to coil leakage. The float trap had to be bypassed.

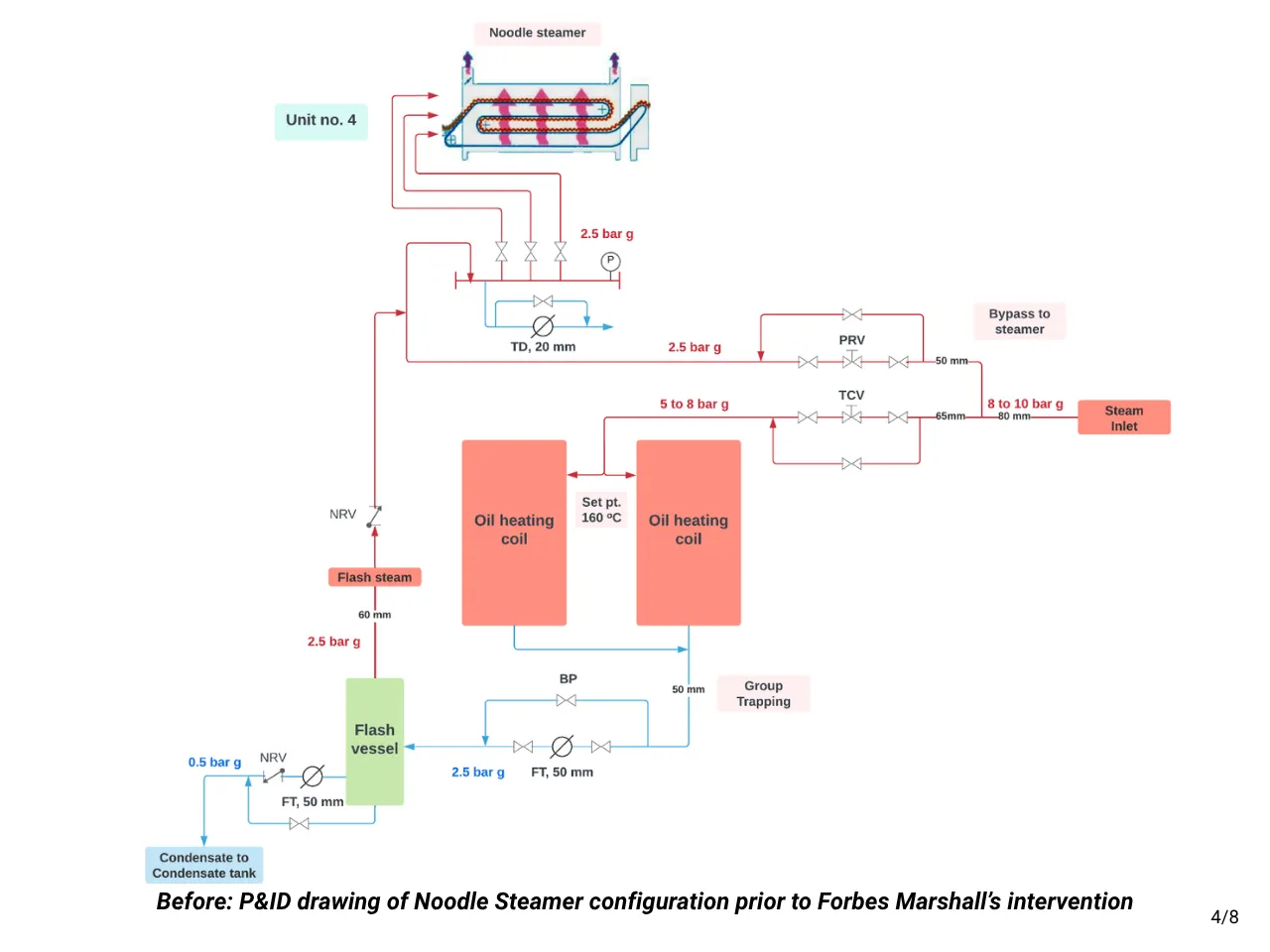

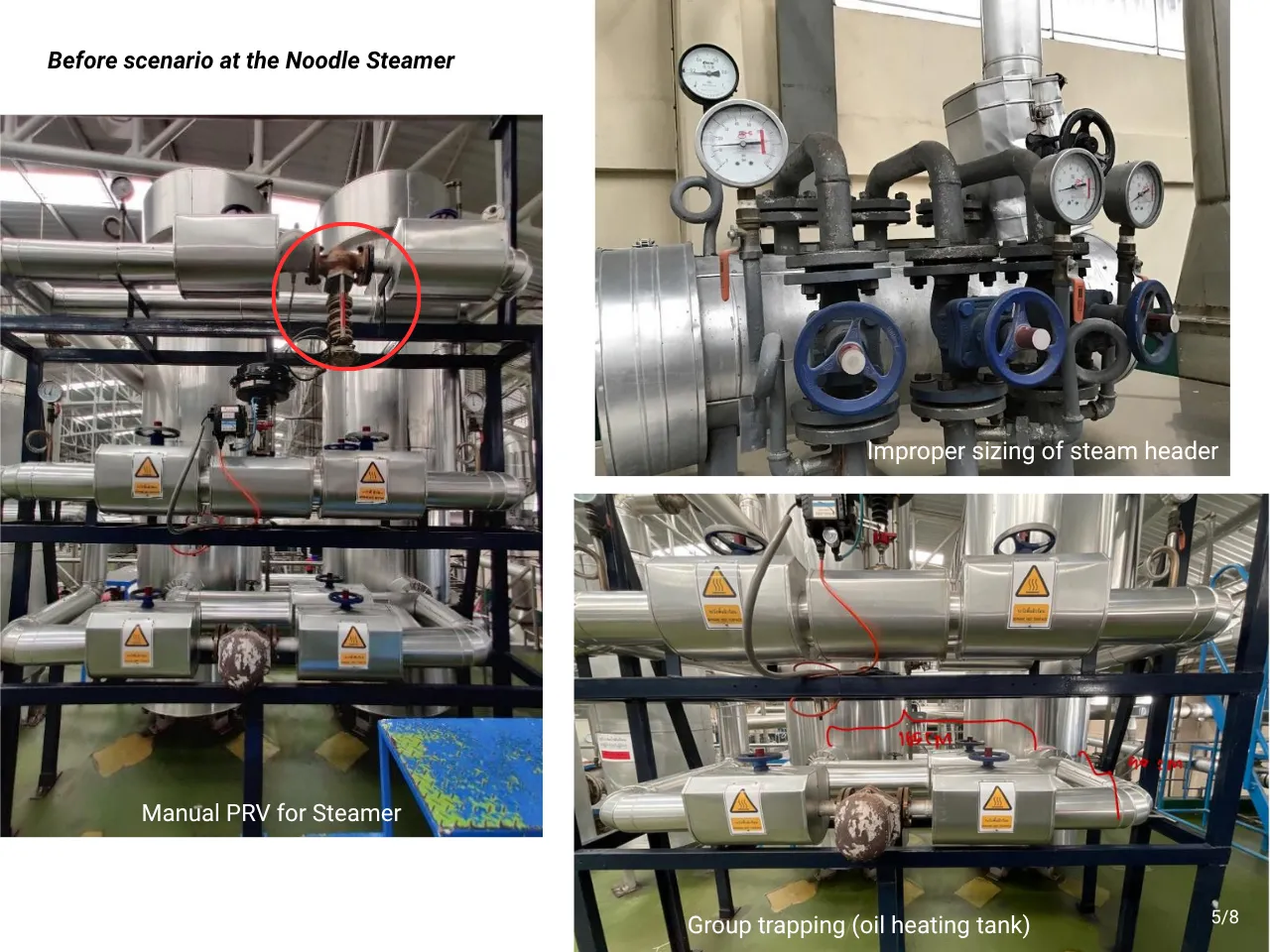

Noodle steamer:

- The steamer was being supplied with excessive steam pressure (up to 2.5 barg).

- A direct acting pressure reducing valve (PRV) on the boiler steam line resulted in non-stable pressure (fluctuation).

- Additionally, the wet flash steam which was also being supplied to the steamer was affecting product quality.

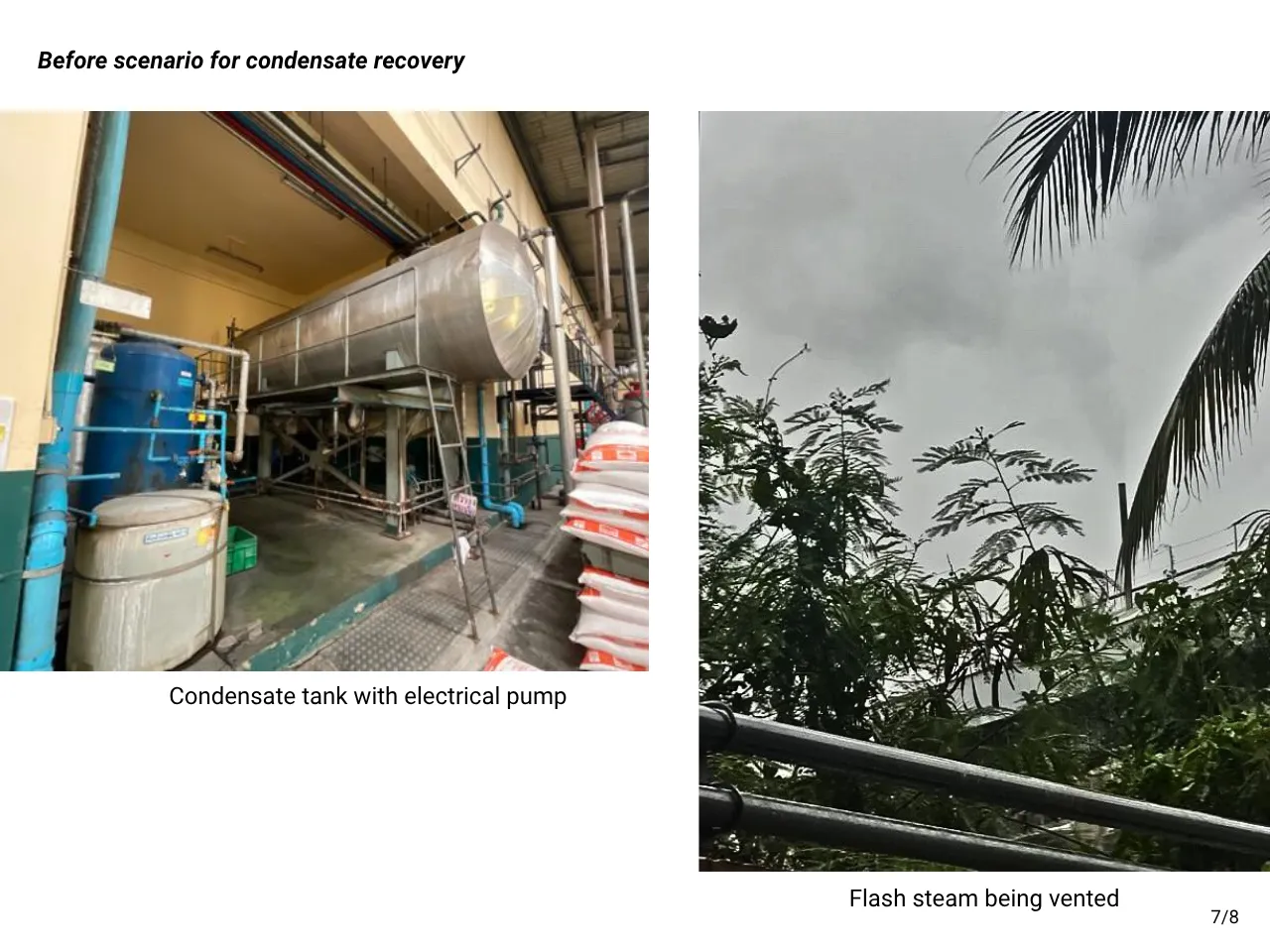

Condensate recovery from Building 3:

- Flash steam vented from the condensate tank.

- The infrequent discharge cycle of the electrical pump resulted in overflow of condensate from the condensate collection tank.

SOLUTION

Forbes Marshall recommended and installed the following:

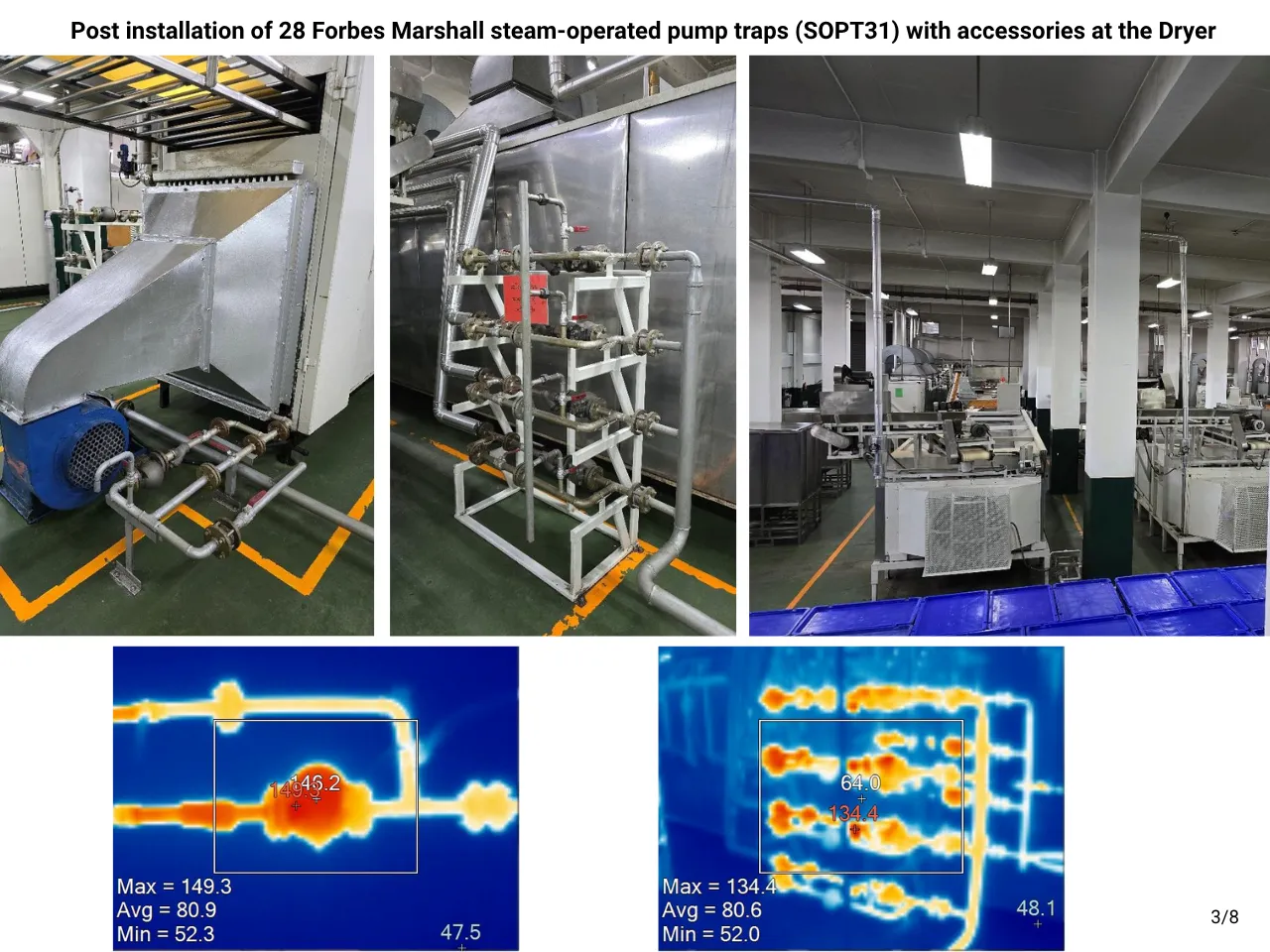

Dyer:

- Recommended individual trapping at each coil, along with replacing the existing thermodynamic traps with correctly sized Single Orifice Float Traps (SOFT) to effectively evacuate condensate, eliminating steam loss.

Fryer:

- Recommend individual trapping for the oil heating coils to stop the coil leakage and bypass opening.

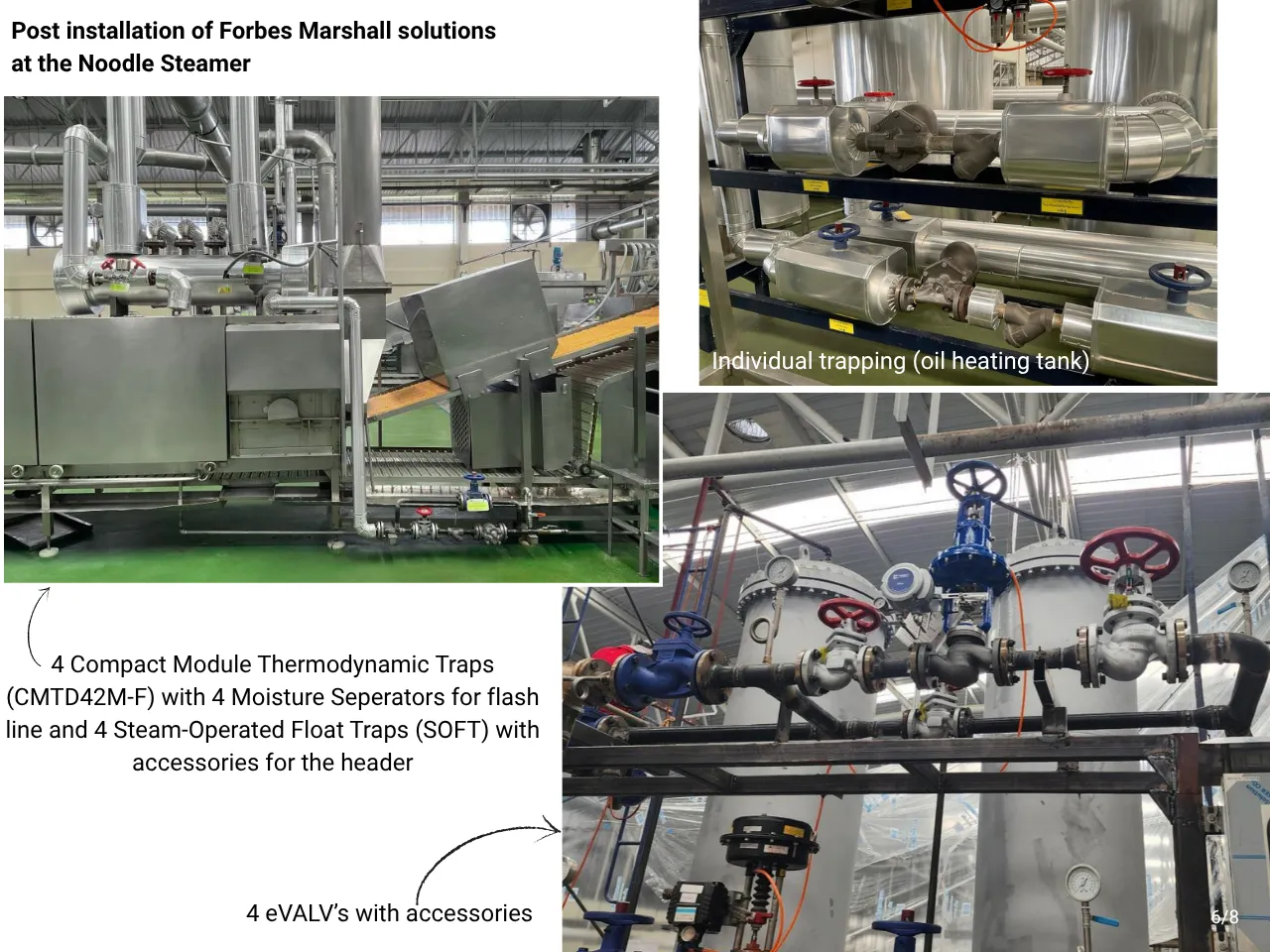

Noodle Steamer:

- Replaced the direct acting PRV on the boiler steam line with a control valve (eVALV) to eliminate pressure fluctuation.

- Installed the moisture separator with a compact module thermodynamic (CMTD42M-F) steam trap to remove entrained moisture in the flash steam line.

- Reduced steamer pressure from 2.5 to 0.5barg.

Condensate recovery from Building 3:

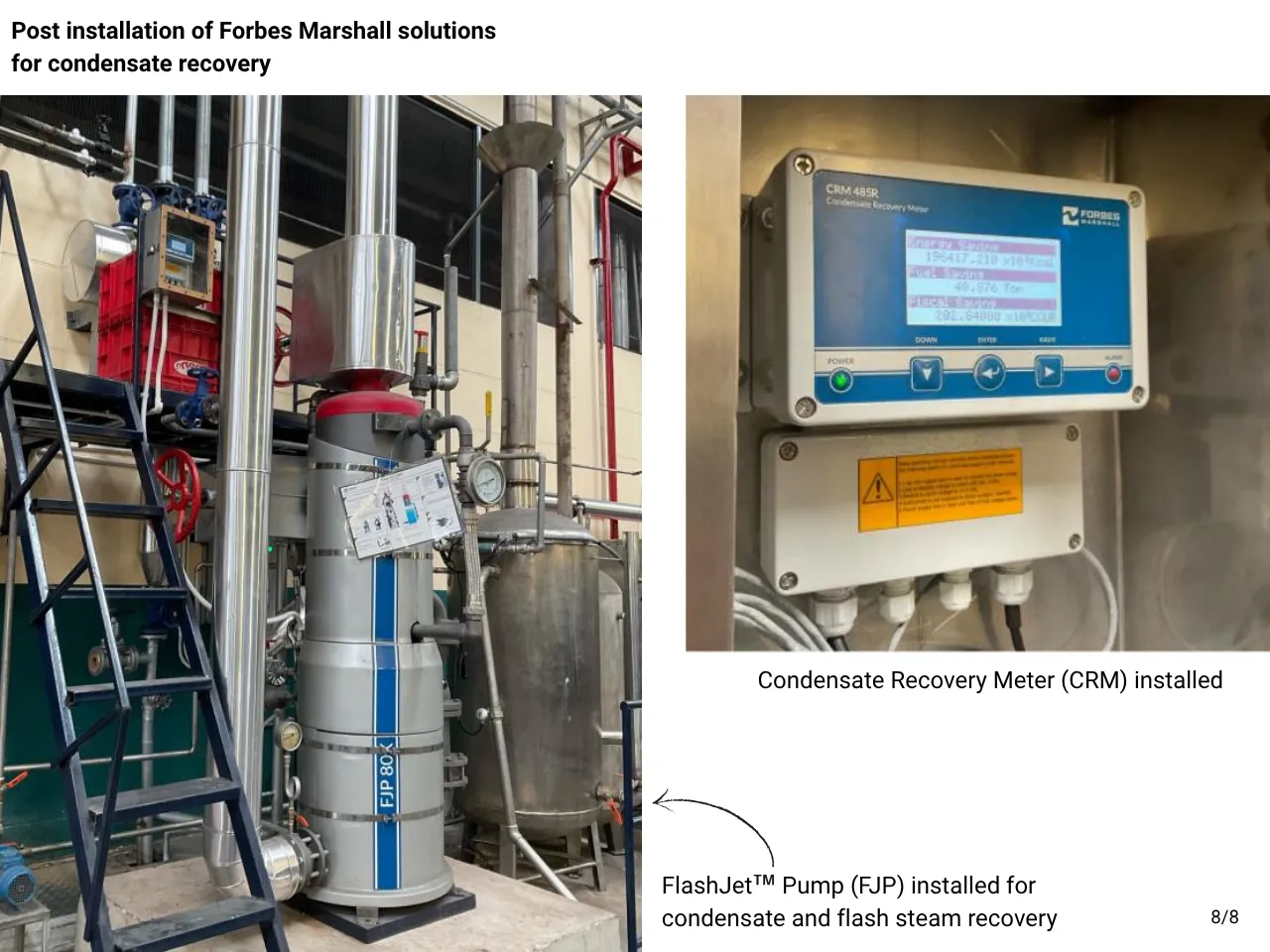

A Flash Jet Pump (FJP80X) with Condensate Recovery Meter (CRM) replaced the intermediate condensate collection tank and electric (centrifugal) pump, enabling recovery of condensate & flash steam back to both feedwater tanks with deaerator head.

BENEFITS

Dyer:

- Achieved the set point temperature without opening the bypass valve.

- Rate of coil leakage decreased to almost zero.

- Production rate increased due to the 10-minute faster heating process.

Fryer:

- Achieved the oil set point temperature without opening the bypass valve.

Noodle steamer:

- Coil leakage eliminated.

- Steam consumption to the steamer reduced.

- The steam dryness improved.

Condensate recovery from Building 3:

- 100°C (212°F) feedwater temperature achieved through condensate and flash steam recovery.

- Feedwater tank overflow issue eliminated.

Overall benefits:

Fuel saving 2.89 TPD (6371 Pounds per day)

Water savings of 3,600 Tonnes (806K Gallons)

Flash steam saving of 7.10 TPD (15.6K Pounds per day)

Annual heat energy savings of 3,464 million kcal (13,737 MMBtu)

Annual CO2e reduction of 2,449 Tonnes (5.3 million Pounds)

Annual monetary savings USD 105,000 (~THB 3,394,650 *converted based on exchange rate)

Products

Associated Services

Process Optimization

Improving Uptime

Forbes Marshal Digital

Associated Services

What to read next