Flue gases released from the boiler chimney contain gases and particulate matter that

pollute the environment.

Continuous monitoring of stack emission is essential to ensure efficient boiler operations and

adherence to environmental norms.

Why Flue Gas Flow

Measurement?

Just measuring the pollutant concentration does not clearly indicate the impact of emissions on the

environment. It is important to measure the composition and concentration of polluting gases

as well as their ‘flow’, so as to arrive at a total discharge of polluting gases to the atmosphere.

Many key design and operating parameters such as specific collection area, gas velocity

(ft/sec)

and treatment time within the ESP can be determined with the help of gas flow

measurement;

For example significant variations in oxygen would show up as large fluctuations in the

gas flow rate.

This would mean decreased ESP performance, which would in turn necessitate

the need to routinely

determine ESP gas volume.

Some of the indicators of excess flue gas causing decreased ESP performance include :

a) Low SCA (specific collection area) values

b) High velocities

c) Short gas treatment times

d) Higher oxygen levels at nearly full load conditions.

Performance Monitoring

For any boiler operation, performance monitoring is essential in order to establish a

good operation and maintenance program. A record of key operational parameters,

right

from day one of boiler operations serves as baseline data which can be used as a

reference point establishing operating and maintenance trends.

Typical parameters to be monitored include:

- Voltage/current

- Opacity

- Gas temperature

- Gas flow rate and distribution

- Gas composition and moisture

Computation of Total Pollutant Release

Legislation often demands that emission measurements are presented in mg/Nm³ where

the expressed volume has been normalised to a standard temperature, pressure and

Oxygen/CO concentration, and where the effects of dilution by water vapour have been

removed.

To compute a measurement of the total pollutant release to atmosphere in kg/hr (or

tonnes/annum), it is necessary to know:

- The pollutant concentration in

mg/m³

- The hot gas flow in m/s

- The cross sectional area at the

point of measurement in m²

The total release is then

calculated as follows:

Mass flow = Mass concentration x

Gas velocity x Area of Duct.

It is vital that all measurements are

made on the same basis. Attempting

to make this calculation using an

actual hot wet gas flow in m/s and

a normalized gas concentration in

mg/Nm³ will produce significant

errors.

Conventional Methods of Flue Gas Monitoring

The commonly used gas flow

monitoring techniques are :

- Ultrasonic Pulse Detection

- Differential Pressure

- Thermal Detection

In all these techniques, the flow monitors (including controller, pressure and temperature

transmitter) are stack or duct mounted.

Ultrasonic Flow Monitors

In case of ultrasonic flow monitoring, the volumetric flow rate of stack gas is measured

by transmitting ultrasonic pulses across the stack in both directions. The time taken to

traverse the distance of the stack, traveling with and against the flow is a function of the

sound velocity and the effluent velocity. The angle at which the ultrasonic pulses need to

traverse the stack or duct is important and is critical to the success of this type of

measurement.

Differential Pressure Flow Monitors

These flow meters work on the principle of measuring differential pressure. They include

S-type pitot tube type, dual-manifold pitot probe type, and annubar type. All these

differential pressure flow rate systems comprise of an electronic, flow-indicating

transmitter that receives pressure and temperature signals from the stack, calculates the

exhaust gas flow rate, and automatically performs electronic drift checks and system

purging. These flowmeters require a lower investment, but are not very accurate and are

susceptible to signal distortion and failure. One of the main limitations is the possible

need to include valves between primary and secondary devices to facilitate removal of

secondary devices for repair or replacement.

Thermal Flow Monitors

These flow monitors measure the electric power required to maintain a constant

temperature of around 24 to 38 Deg.C. above the exhaust gas temperature in a flow

sensor. Both single-point and multi-point analysis options are available in the market.

However, the use of these types of flow meters is limited to clean, non-abrasive fluids.

Even the slightest moisture can lead to measurement inaccuracy. It is essential to know

thermal properties of the gases, as variation from the calibrated values can result in

inaccurate readings.

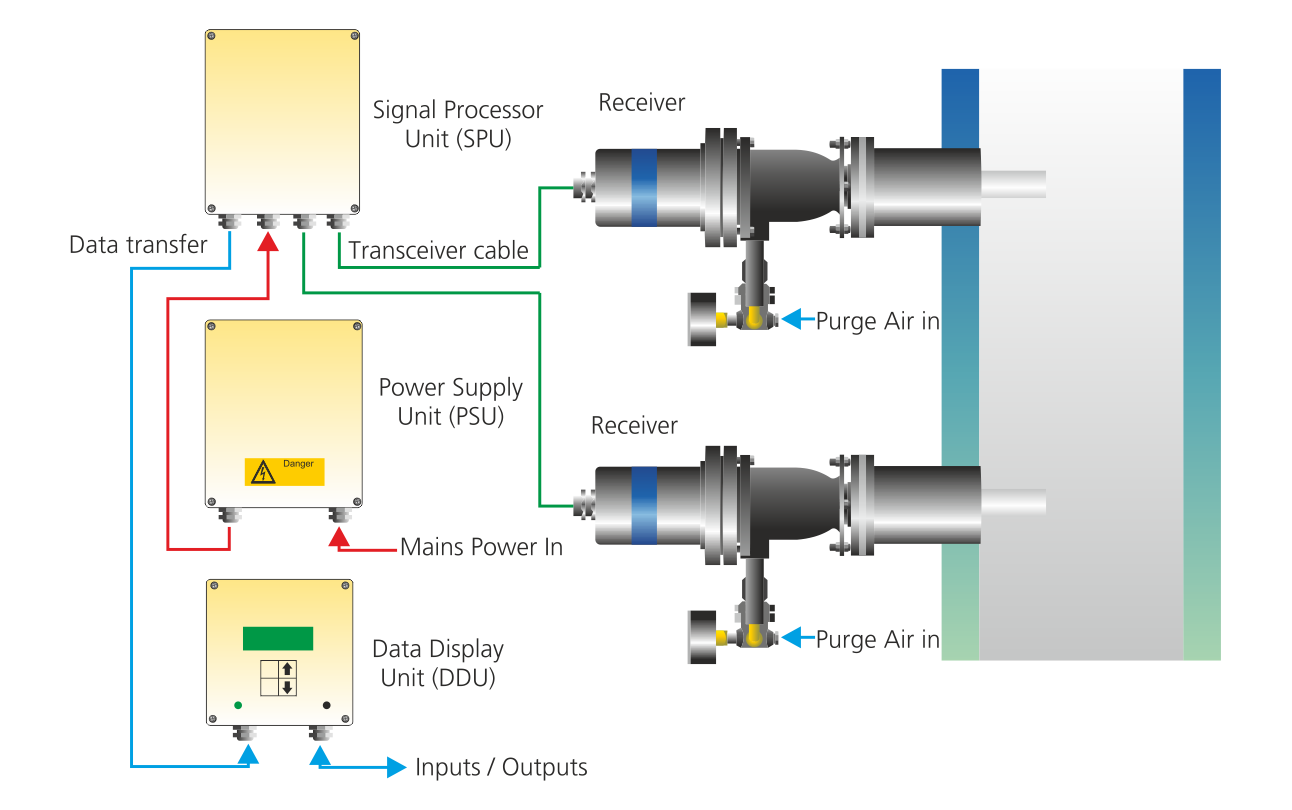

In-situ Non-contact Measurement : The Preferred Technology

As seen above, conventional methods are not very accurate. The modern in-situ

technology provides accurate and reliable results. These analysers provide non-contact

measurement of gas velocity using a time-delay correlation of flue gas infrared

emissions received by two detectors placed at a fixed distance apart, and are easy to

operate and maintain.

This technique is suitable for all combustion gases, including hot gases and gases with a

high dust burden. Two robust infrared detectors are used for prime sensing. These

detectors are mounted on the stack or duct, typically one meter apart in the direction of

flow. High efficiency air curtains are also fitted, which extend the time between

maintenance periods and window cleaning.

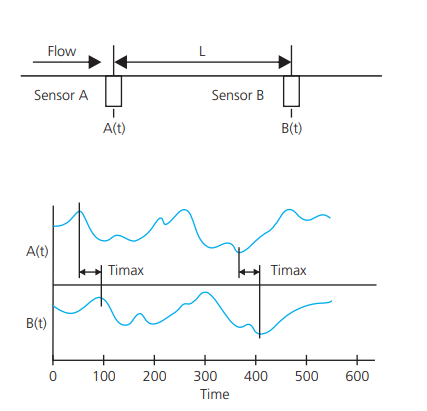

Principle of Operation

The method used is similar in principle to the technique of flow measurement by the

injection of chemical dye or radioactive tracers, where the velocity is derived from the

transport time of the tracer between two measuring points that are known distance

apart.

Instead of an artificial tracer being added, the naturally occurring turbulence of the gas

stream is used as the tracer. This flow turbulence causes fluctuations to occur in infrared

radiation emitted by the gas. This continuously variable turbulent pattern is monitored by

two infrared detectors mounted typically one meter apart along the direction of gas flow.

An electronic correlation technique is used to continuously compare the two detector

signals to determine the time delay between these signals imposed by the gas velocity.

Typical signals from the sensor A and B are shown here.

The signal from sensor B shows a strong similarity to that from sensor A. This signal

from sensor B is delayed by a time t, which is the time taken for the gas to flow from

point A to point B. Continuous determination of the detector signal time delay by the

signal processor unit produces a continuous measurement of gas velocity since Velocity

V = L/t, where L is the distance between two sensors.

Benefits

- Accurate and reliable

- Suitable for hot, dusty and aggressive gases

- No moving components, hence easy to maintain

- Low maintenance ensures high measurement availability

- Available with automated span checks for high and low span

- Results available locally due to local digital display and control unit