Due to the changing weather conditions and depleting sources, water has become a critical resource and

conservation is very vital for the present and future generations.

Needs :

Sustainable ecosystems focus on energy, emissions and water and wastewater.

Water conservation revolves around actions to Reduce, Recycle and Reuse.

The main considerations for water sustainability initiatives are:

- Business sustainability

- Corporate social responsibility

- UNGC, United Nation Global Compact, GRI (G4)

- LEED / GRIHA ratings for facilities

- Government norms and incentives on water use and discharge

- Sustainability disclosure reports

- Reduction and reuse of water

Benefits of water conservation :

- Reduced per capita consumption

- Identification of potential usage (or wastage) points

- Detection of leakage points, reduced pumping costs

- Benchmarking of water harvesting, reuse and generation

- Water balancing

- Savings on water cost

- Compliance to government norms

- Optimised asset management

Automation and Instrumentation Solutions for Water

State of the art instrumentation and automation systems for water and sewage have the capability for central control of water and wastewater with geo tagging facility to integrate all networks from a single command center.

These systems comprise of technology driven instruments such as flow meters, pressure transmitters and gauges, temperature transmitters, level transmitters, chlorine, turbidity analysers, pH analysers, ammonia analysers, MLSS analysers and special multiparameter water quality analysers for COD, BOD and TSS. These high-end analysers not only continuously monitor water quality but also enhance operation performance by the way of automation.

These systems help to benchmark water consumption, quality of treated water, cost of treatment and quantity of water conserved and reused.

All this information can easily be accessed in ready to use pdf/excel reports on a daily, weekly, monthly and yearly basis.

Instrumentation : Basic Building Blocks

|

Flow

|

pH

|

Vibration Sensors

|

|

Level

|

TDS/TSS

|

Vibration Monitors

|

|

Pressure

|

Chlorine

|

Flow & Pressure Switches

|

|

Temperature

|

Turbidity

|

Gauges

|

|

|

COD/BOD

|

|

1. On line water flow consumption measurements

If you cannot measure it, you cannot improve it. - Lord Kelvin

Today metering has many perspectives. Right metering helps to analyse consumption patterns, identify leakages, calculate efficiency of pumps, depict NRW (non-revenue water), asses the performance of WTP/STP/ETP, monitor the per capita water consumption, identify inefficient fixtures, etc.

In contrast to mechanical flow meters of the past, smart digital microprocessor based online flow meters are now the backbone of any water management success story. The inline fit and forget magnetic inductive flow meters are the preferred option. These flow meters are very sensitive and provide accurate digital output. With modern technology, remote metering is available, with outputs accessible several kilometers away from the point of measurement. This facilitates data to be easily incorporated with existing BMS (Building Management System) or DMS (Data Management System). The latest trends of Industry Internet 4.0 play a vital role in data transmission and easy connect / re-connect to the network of such measurements.

Online Flow Measurements:

Smart water metering offers the following benefits to users :

- Huge reduction in water consumption on per capita basis.

- Identification of major leakages in the pipes as well as storage tanks.

- Identification of potential usage points.

- Increased efficiency of sewage treatment and water treatment.

- Water balance of the entire facility/ campus.

- Water consumption data available for all locations.

- Data collection without manual efforts.

2. Analytical instruments for various processes in water treatment, effluent and sewage treatment :

Statutory norms stipulate various parameters to be measured. This ensures better process health and environment health.

- pH, TDS, ORP, Conductivity

- COD-BOD-TSS-PH

- Ammonia

- Nitrate

- DO

- Sludge level

- Turbidity/ TSS

- Sulphide

- TOC

- Oil In water

- Phenol

- Color

- Cyanide, Chromium VI

- Arsenic and other heavy metals (Fe, Mn, Mg, Cu, Cr6, Al, Zn)

- Sulphates and phosphates

The key is to have maintenance free analysers with very little or no reagents or consumables, auto zero during cleaning cycles, quick response time, no choking or filtering required for sensors and so on. It is now mandatory for upcoming treatment plants to have an O&M contract and hence the analysers supplied should have longevity and availability of spares and consumables for the life cycle of the product at least for 5-7 years of operation.

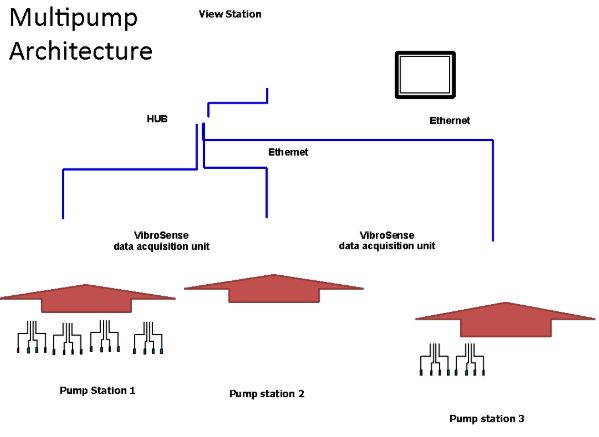

3. Vibration monitoring and analysis for all rotating equipment

Of all the various maintenance technologies, vibration analysis provides the greatest payback when adopting a predictive maintenance program for rotating equipment like fans, motors and pumps . In water processes, pumps are the most vital. Insufficient lubrication, fatigue and machine problems like imbalance, misalignments and loads create high stress on bearings resulting in failures. Vibration and condition monitoring helps increase machine life, increase process efficiency, reduce downtime, prevent unplanned shutdowns and cost saving in terms of machine parts/power.

Vibration is measured using an accelerometer or a velometer sensor that is mounted in horizontal and vertical direction on each bearing housing. Direction of sensor action should be perpendicular to shaft rotation. The signal from the sensor is connected to a monitor - a transmitter or multitransmitter rack which provides for raw data output – very essential for machine analysis , site indication /centralised monitoring , 4 to 20mA signal and Modbus communication signals, relays for emergency tripping and so on.

Analysis software will help users check short term/long term machine health. Alerts are sent by central monitoring systems to experts by email /SMS in case of any untoward condition. Timely tripping messages are also sent to the operator thereby avoiding major breakdowns. The software indicates probable causes of problems and displays all the information in the form of FFT, spectrum, waveform and plot graphs.

4. Pressure and level measurements with remote data transmission all along the water cycle

The combination of flow and pressure monitoring is essential in smart infrastructure for asset monitoring and long term sustainability. Pressure measurement and analysis of pressure trends at various nodes in the water distribution network play a crucial role in water conservation.

Pressure is a key indicator for identification of water leakages in a network. It is estimated that only 10% of water losses in well monitored and controlled networks are caused by larger pipe bursts. The balance 90% is due to smaller leaks which often go unidentified. The cost of leakages is the summation of cost of delay in identification the leak, cost of identification of actual point of leak and the cost of time consumed in repair of leak. The analysis of pressure trends at different nodes help in forecasting possible leakages at any point in the network thereby avoiding costs in delay of identification of and ascertaining actual point of leak.

Level measurement too is vital to water conservation. Continuous measurement at tanks, reservoirs and basins monitor the level of water and help take proactive action to close water lines when required, thereby avoiding wastages. It also an important parameter for non-revenue water (NRW) calculation, required at the central location/control room. Level in each tank is measured and monitored to ensure conservation by water balance. Calculation of water balance is also essential for proper analysis.

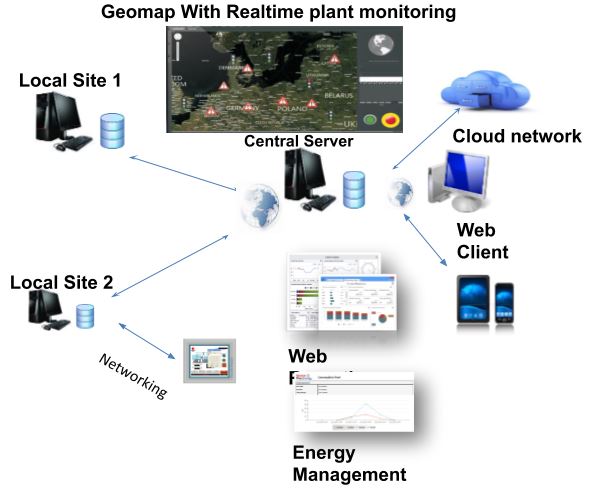

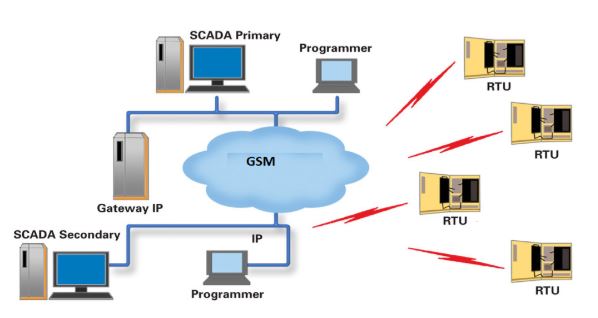

5. Central programmable logic and SCADA controls:

The latest technologies in SCADA for water application incorporate geo- tagging and geo-map features, 2D and 3D graphics, customised on the fly reports and trends, web based control of the entire process from any location and integration at various locations under a single tree. They use latest IoT frameworks that connect with 3rd party devices to share relevant information.

The system supports hierarchical (plants to equipment) control in one window with remote operation

and incorporates fast and efficient engineering with auto documentation, easy definition and reuse of process objects to integrate the control logics and HMI faceplates. Standard algorithms are programmed to calculate NRW, MTD, daily and YTD calculations with automatic time synchronisation and backup.

Programmable Logic Controllers (PLC) and Remote Terminal Units(RTU) enable local measurements for plant wide visibility; local controls to provide master override and bypass aid decision making by pin pointing faults and overruns. The system benchmarks per person, per batch and per location consumption thus facilitating daily decisions and helping to plan interventions. Uptime enhancement and proactive maintenance (planned v/s emergency shutdowns) enhance the life of local equipment with fast trips and failures and helps in continuous improvement of productivity and throughput of the system.

Author:

Sanjay Pherwani

Head - Water Vertical

Forbes Marshall Group