Edible oils and fats are an integral part of the food industry. Besides being widely used domestically, the processed food industry also contributes largely to the use of edible oil worldwide.

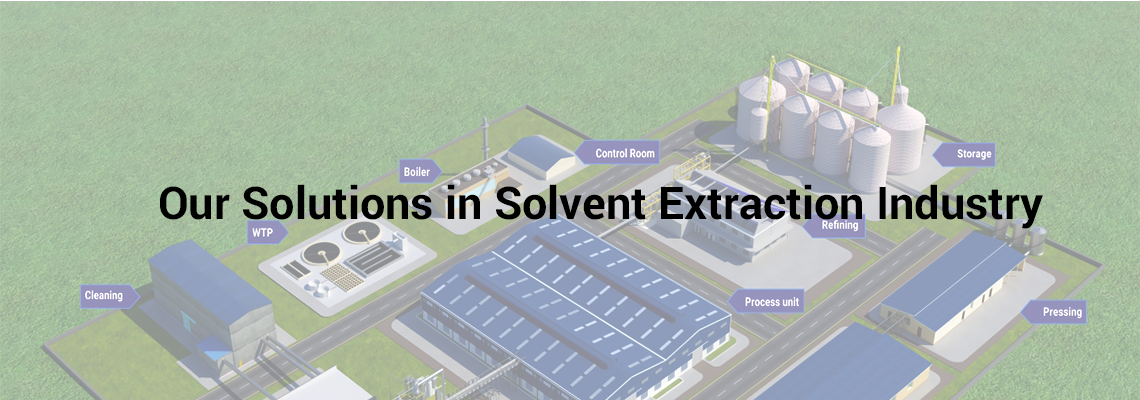

Different types of edible oils like rice bran, sunflower, palm, castor, mustard, soya, among others, are manufactured in two stages

1) Oil extraction, either mechanically or with the help of solvents

2) Physical or chemical refining

Oil seed prices vary depend on factors like weather and geographical conditions, transportation costs and market demand. The manufacturing of edible oil from these seeds is thermal energy intensive; typically thermal energy accounts for about 30% of processing costs.

Like seed costs, there has been a constant increase in the cost of fuel required for the extraction and refining process. These factors contribute to the increased the cost of production, and it is imperative to optimise processes and implement energy management practices to reduce operational costs while meeting ever-growing demands.

For over 75 years, Forbes Marshall has provided innovative products and services to help industries improve their process and energy efficiency and be more environmentally responsible. We help build and sustain highly efficient

plants that comply with regulatory requirements. Our solutions help plants

- Reduce the cost of thermal energy generation

- Reduce plant-wide and equipment-wise specific steam consumption

- Improving process efficiency and product quality

We have worked with over 400 edible oil plants globally, and carried out over 300 energy audits and utility design consultancies, typically reducing OPEX by about 21%. Working in collaboration with the plants, we have been able to reduce the Industry's overall impact to the environment.

Energy Savings

2,00,000 MWh/Year

Water Savings

5,00,000 Ltr/Year

CO2 Reduction

1,80,000 Tons/Year