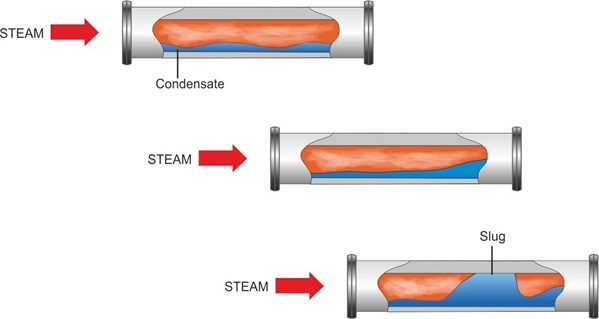

Accumulated condensate in steam lines often leads to water hammer, resulting in damage to the steam system and wastage of energy due to steam leaks. To reduce the possibility of leaks, drain condensate at regular intervals.

As steam travels from the boiler it begins to lose its heat and condenses into

water. The hot water formed, known as condensate, does not transmit heat

effectively and hence needs to be removed from the steam system.

If condensate is allowed to accumulate, the overall effective cross sectional area

of the pipe reduces. This causes steam velocity to increase above the

recommended limits. The mixture of steam and condensate at high velocities is

damaging as it leads to erosion and water hammer

Water hammer is the phenomenon caused by slugs of condensate colliding at

high velocity into pipework fittings, and equipment. The resulting erosion and

corrosion of the pipework and equipment create leaks in the steam system.

Reduction in pipeline leakage leads to reduced steam consumption and thus a

lower fuel bill.

Fig: Condensate slug carried along the pipe collides with pipe walls or with the

pipework fittings leading to erosion.