Debottlenecking a bottle washer, saving fuel for a aerated beverage MNC in Thailand

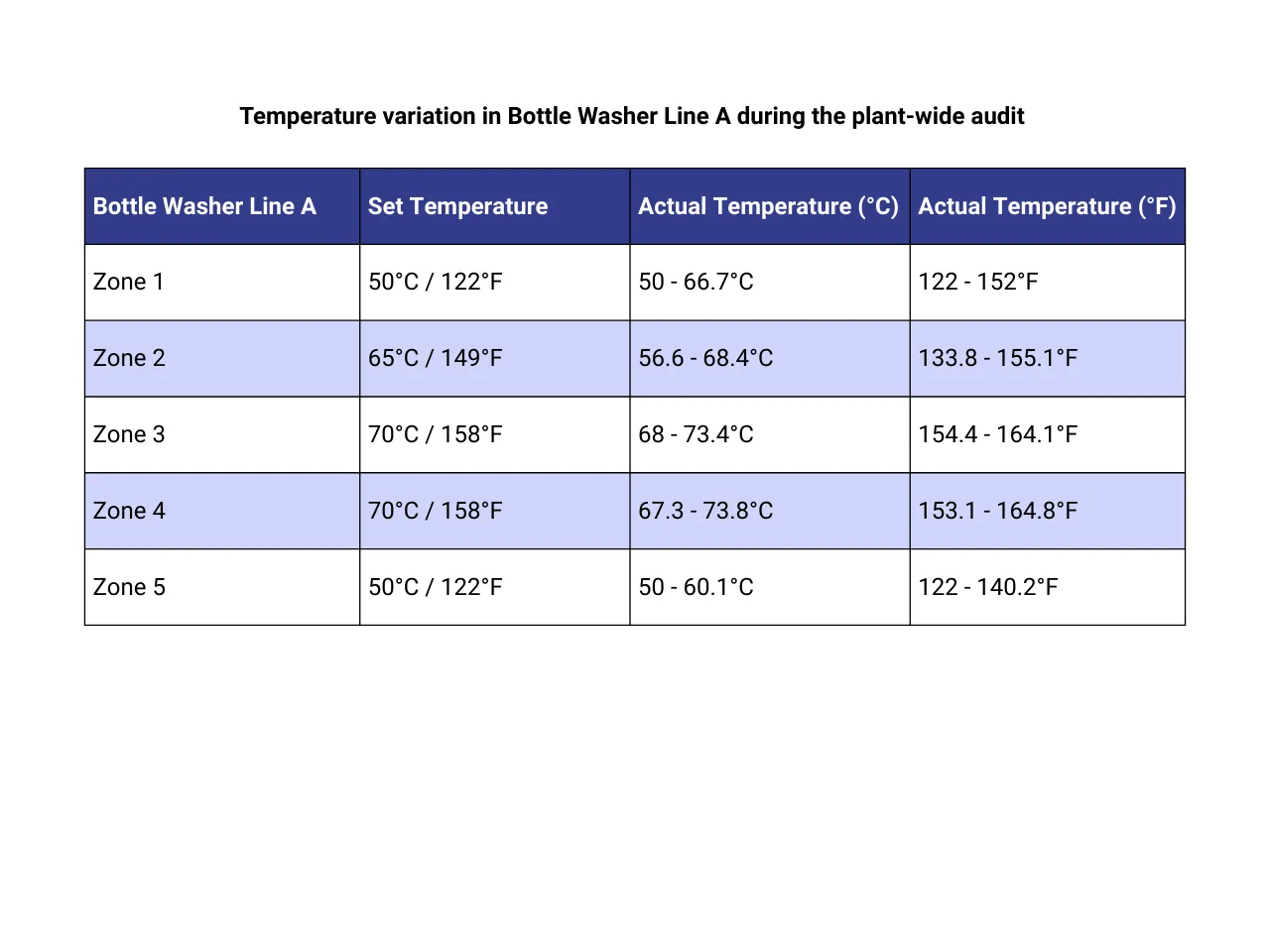

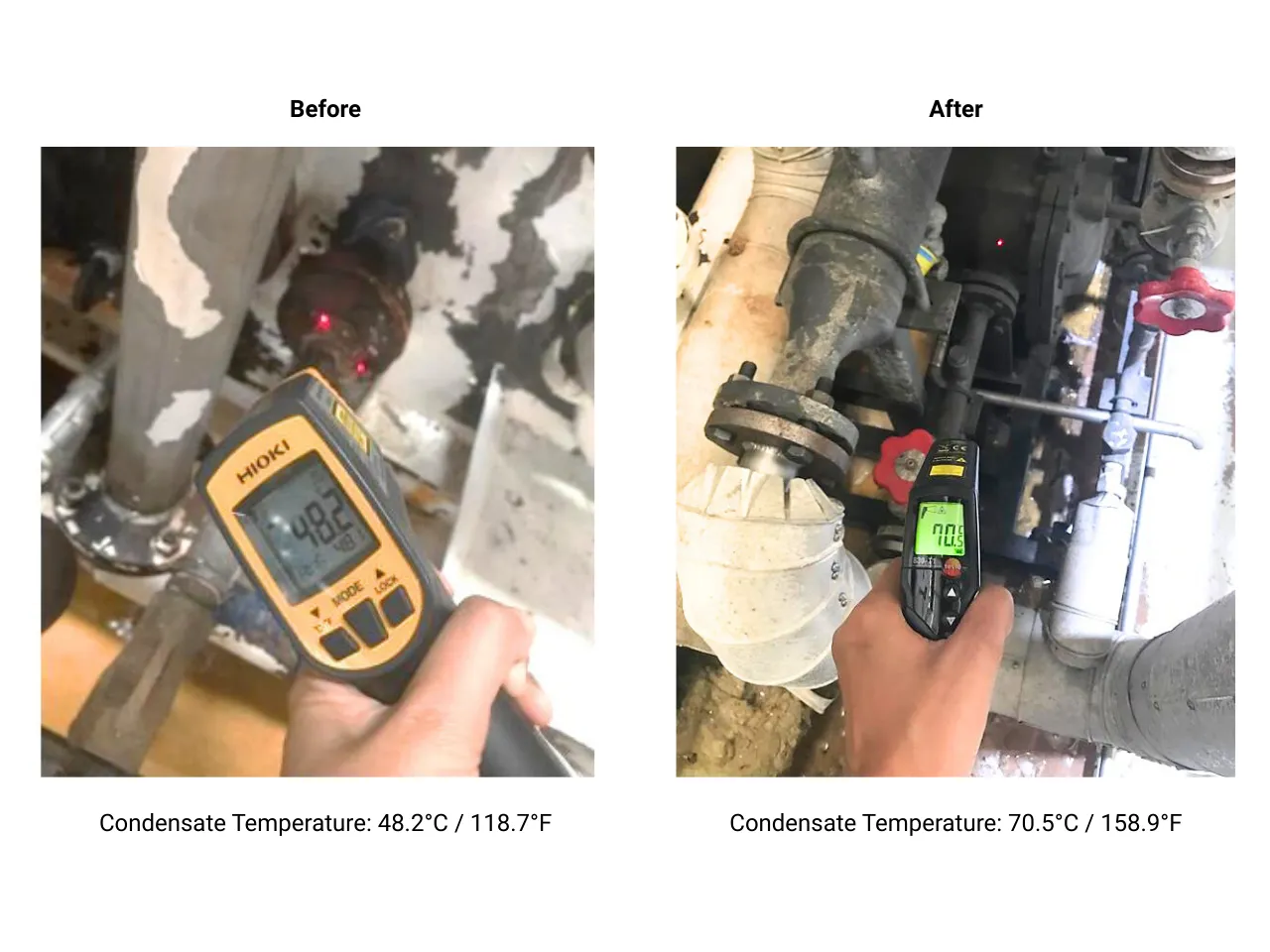

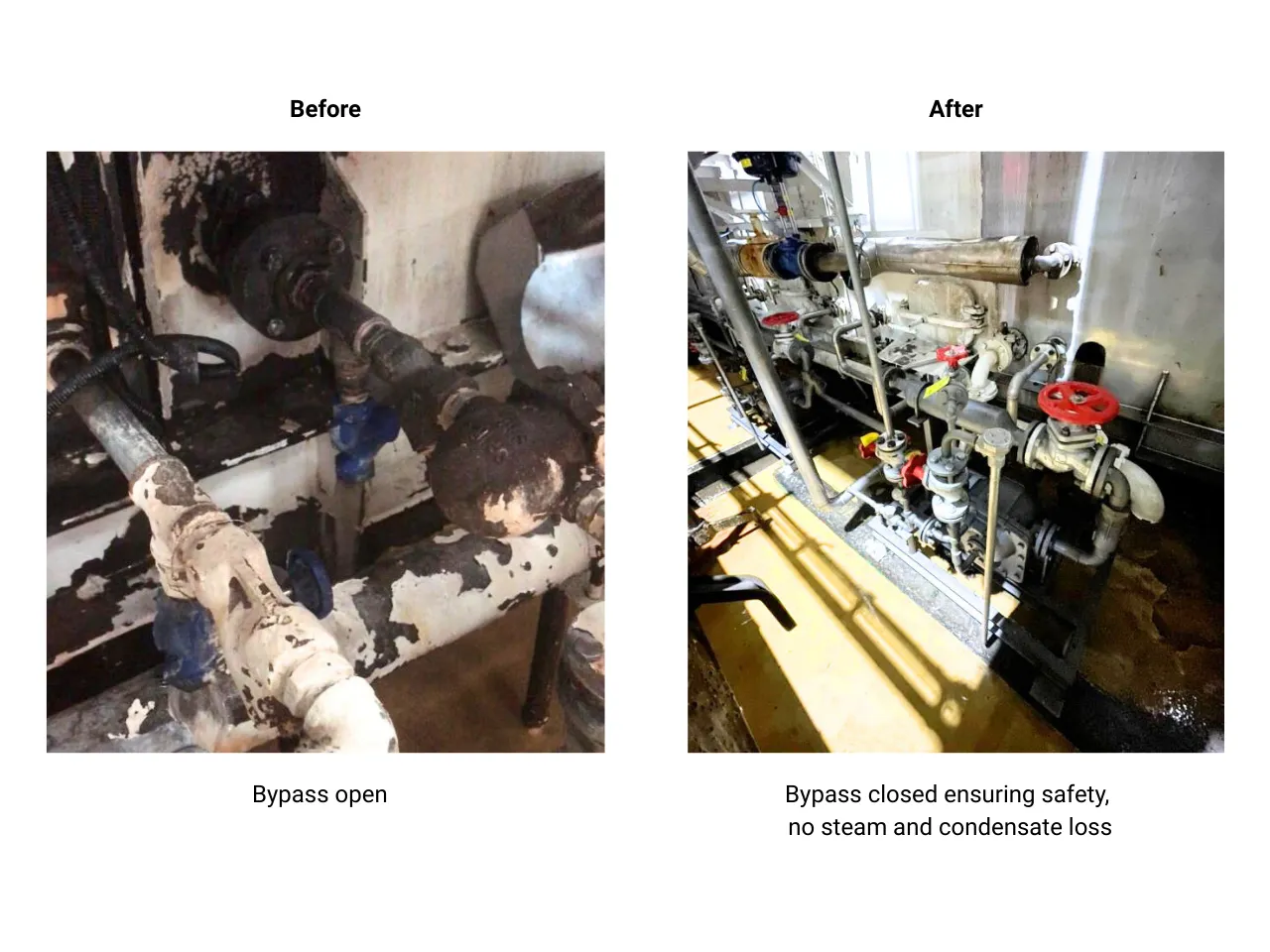

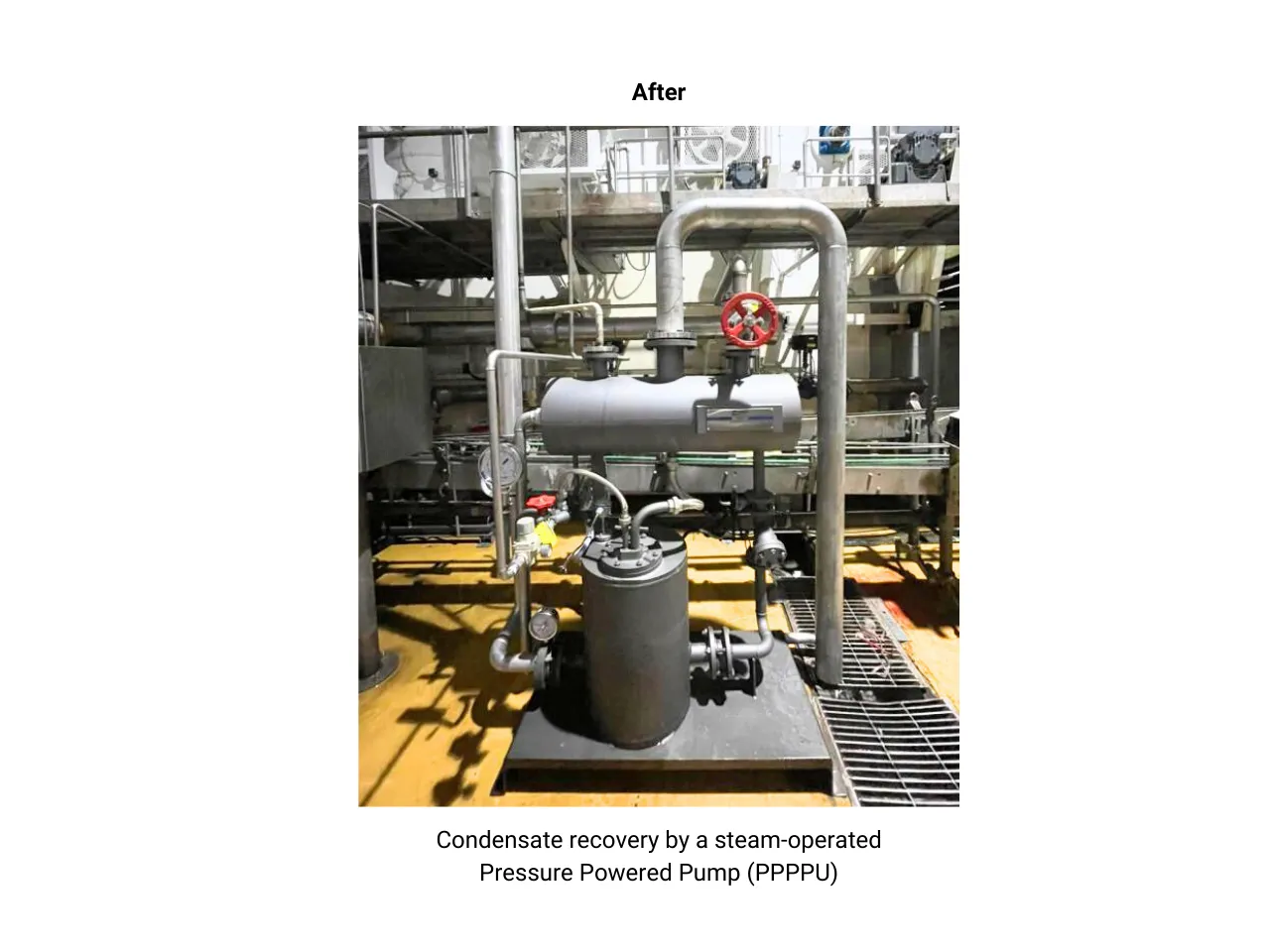

Forbes Marshall conducted a plant-wide energy audit for a beverage MNC in Pathum Thani, Thailand. During our assessment we observed the Bottle Washer steam traps were being bypassed. This led to local drainage of condensate and loss of steam. Detailed investigation indicated the plant was facing significant variation in their process temperature for Bottle Washer Line A. Plant personnel explained that bypassing the traps helped them achieve the required temperature.

Products

Associated Services

Process Optimization

Improving Uptime