Debottlenecking PET Warmer Line at a Beverage Plant in Thailand

A beverage MNC in Pathum Thani, Thailand was facing two scenarios in their PET line warmer:

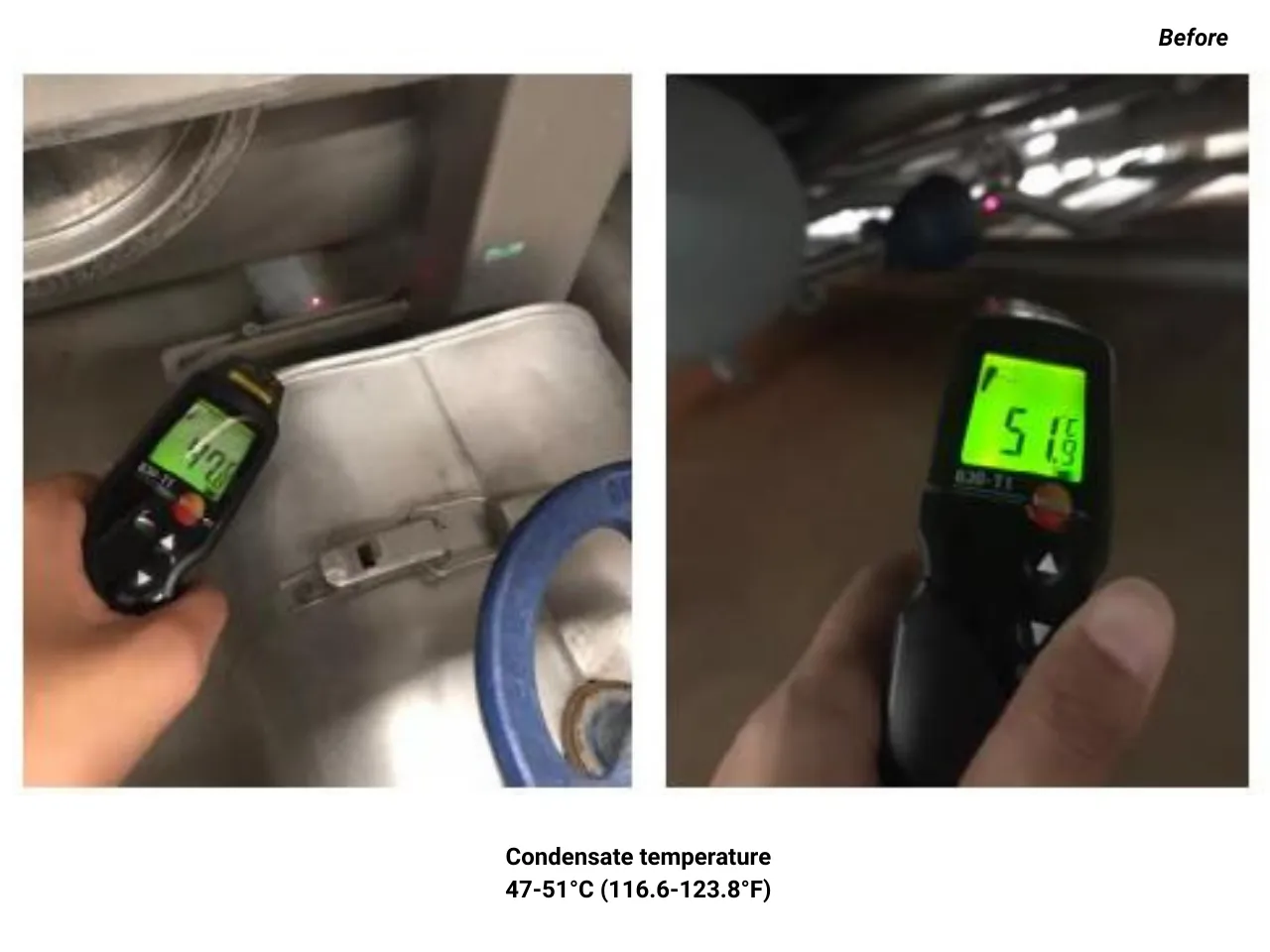

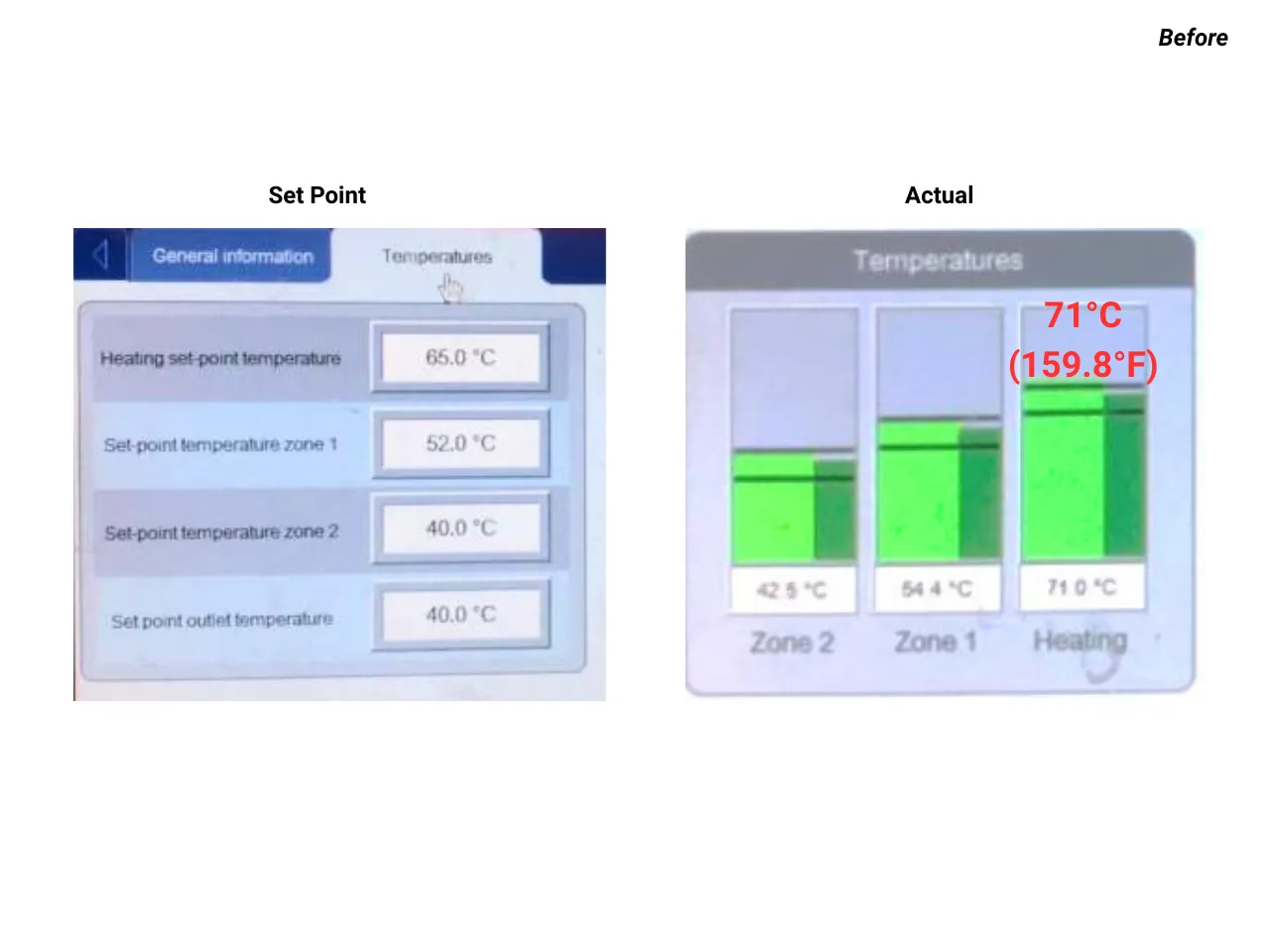

- Condensate temperature was 50°C (122°F), indicating stalling in the heat exchanger. This was impacting the process temperature (significant variation with respect to the set point) and heating time (which was longer).

- Process temperature was exceeding the set point temperature by 10°C (50°F).

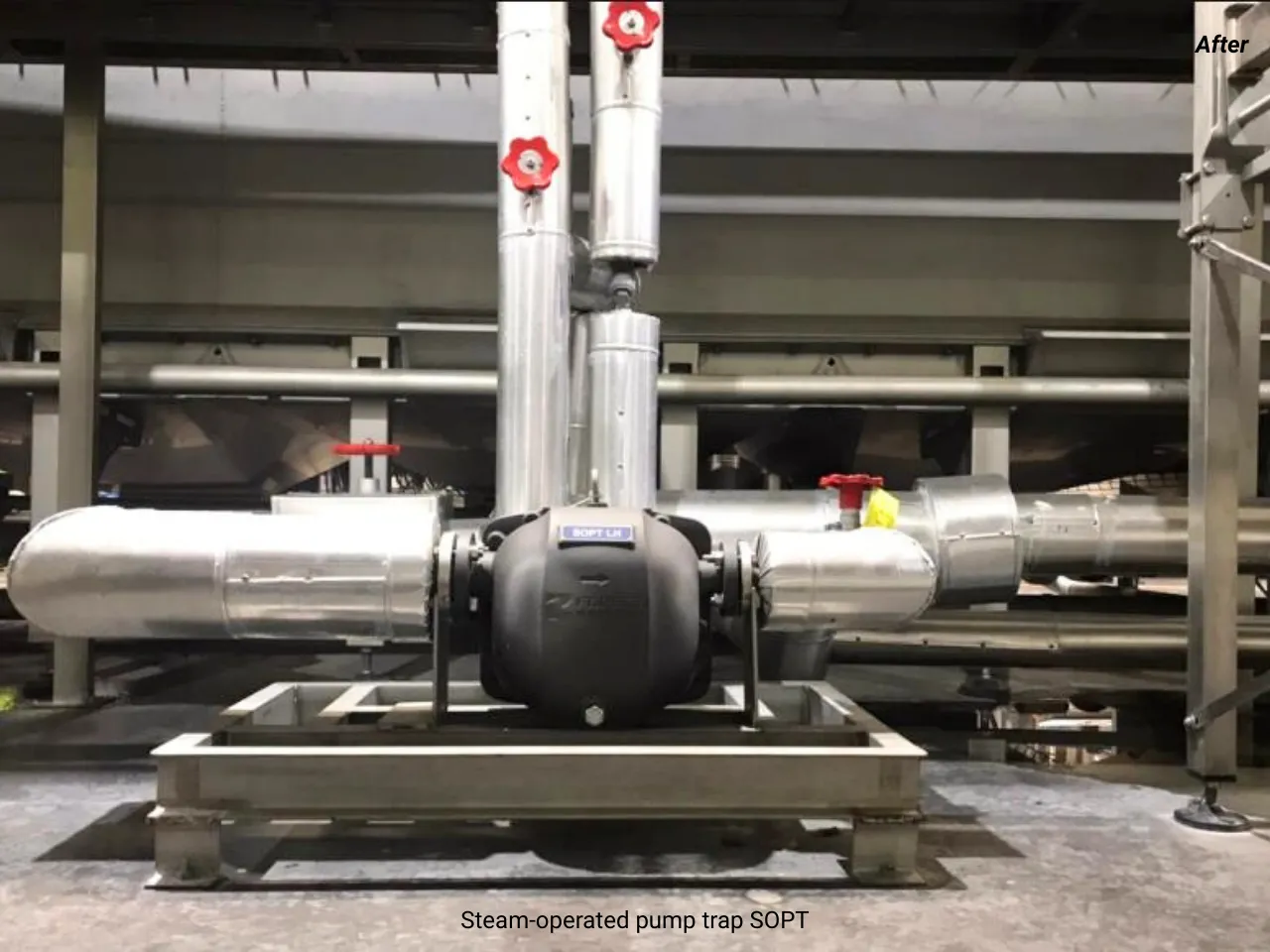

An energy audit of their steam system design and installation of a steam-operated pump trap (SOPT) along with a pressure powered pump package unit (PPPPU), helped the plant to resolve issues with process and condensate temperatures enabling 100% condensate recovery.

Products

Associated Services

Process Optimization

Improving Uptime