Increasing the condensate recovery by 37% for a garment manufacturer in India using FM Digital

A prominent garment manufacturer and exporter in Tamil Nadu, India was unable to achieve their net-zero goals over the last two years. With steam intensive processes such as iron baths and tumble dryers, they found it difficult to identify and sustain energy-saving opportunities. Global buyers in the garment industry have mandated meeting specific sustainability targets, and hence as a supplier, meeting the mandate deadline was essential.

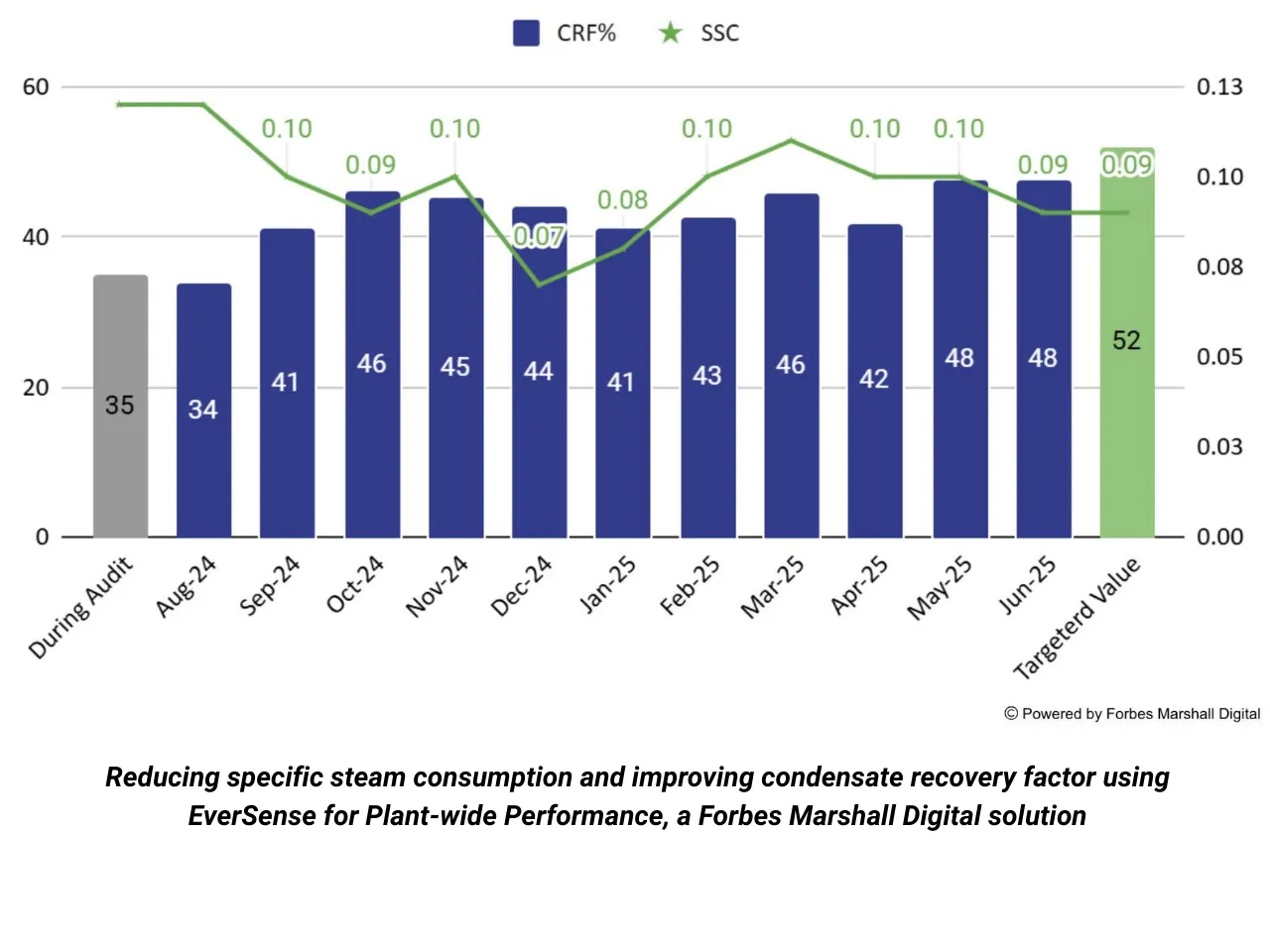

To address this challenge, our Forbes Marshall Digital partnership with this garment plant began in August 2024 with a shared objective of improving efficiency, enhancing CRF, and supporting their journey towards net-zero using EverSense for Plant-wide Performance.

Products

Associated Services

Process Optimization

Improving Uptime