207 Kilograms (59 Gallons) of furnace oil fuel saved daily for a Beverage MNC in Thailand

A beverage MNC in Rangsit, Thailand was experiencing issues in their Pasteuriser Hot Fill line 3 due to stalling. Forbes Marshall conducted a plant-wide survey and recommended and implemented solutions for this area.

PROBLEM

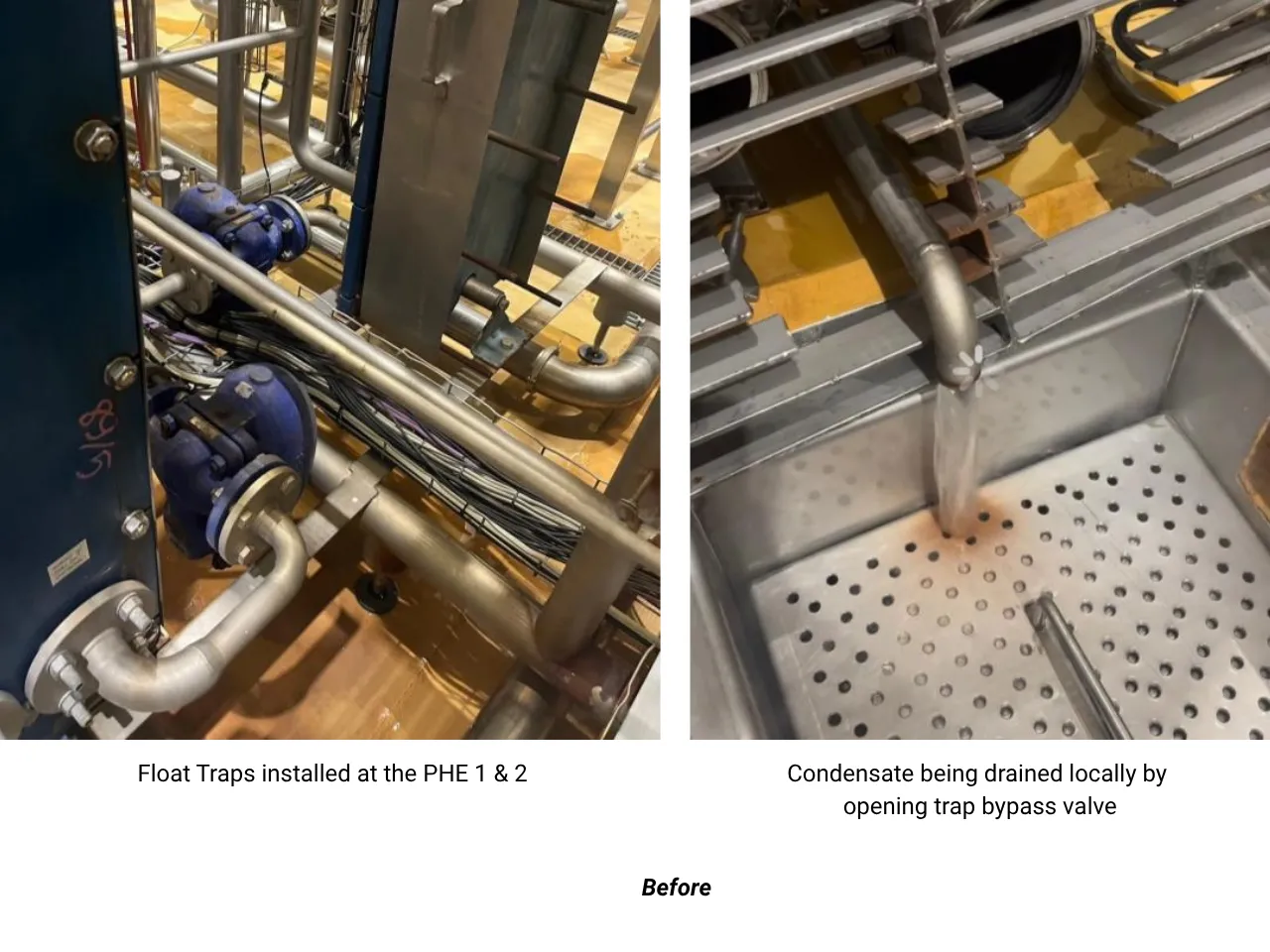

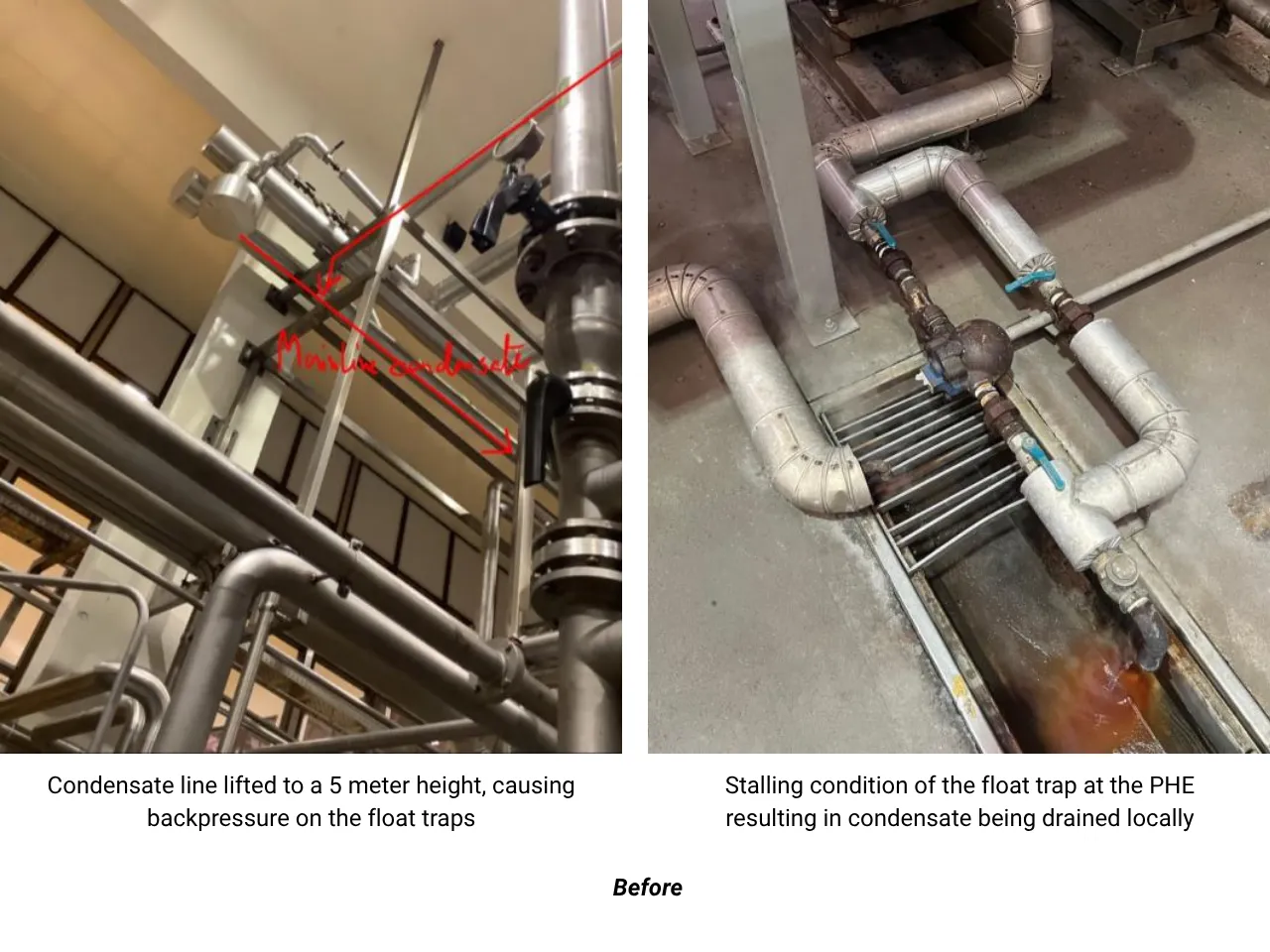

During our assessment we observed the Pateuriser Hot Fill line 3 was using float traps, which were experiencing condensate stalling due to low process temperatures. Due to stalling the operator was keeping the trap bypass valve open, draining condensate locally.

Additionally, the condensate line was lifted to a 5 meter height and recovery was by trap pressure. This further increased the backpressure on the float traps.

Steam was being supplied at 5-6 barg and the PID control valve had to be manually opened to 100% to maintain targeted product temperature of 97°C (206.6°F).

Issues of leakage detected in two of the three plate heat exchangers (PHEs).

SOLUTION

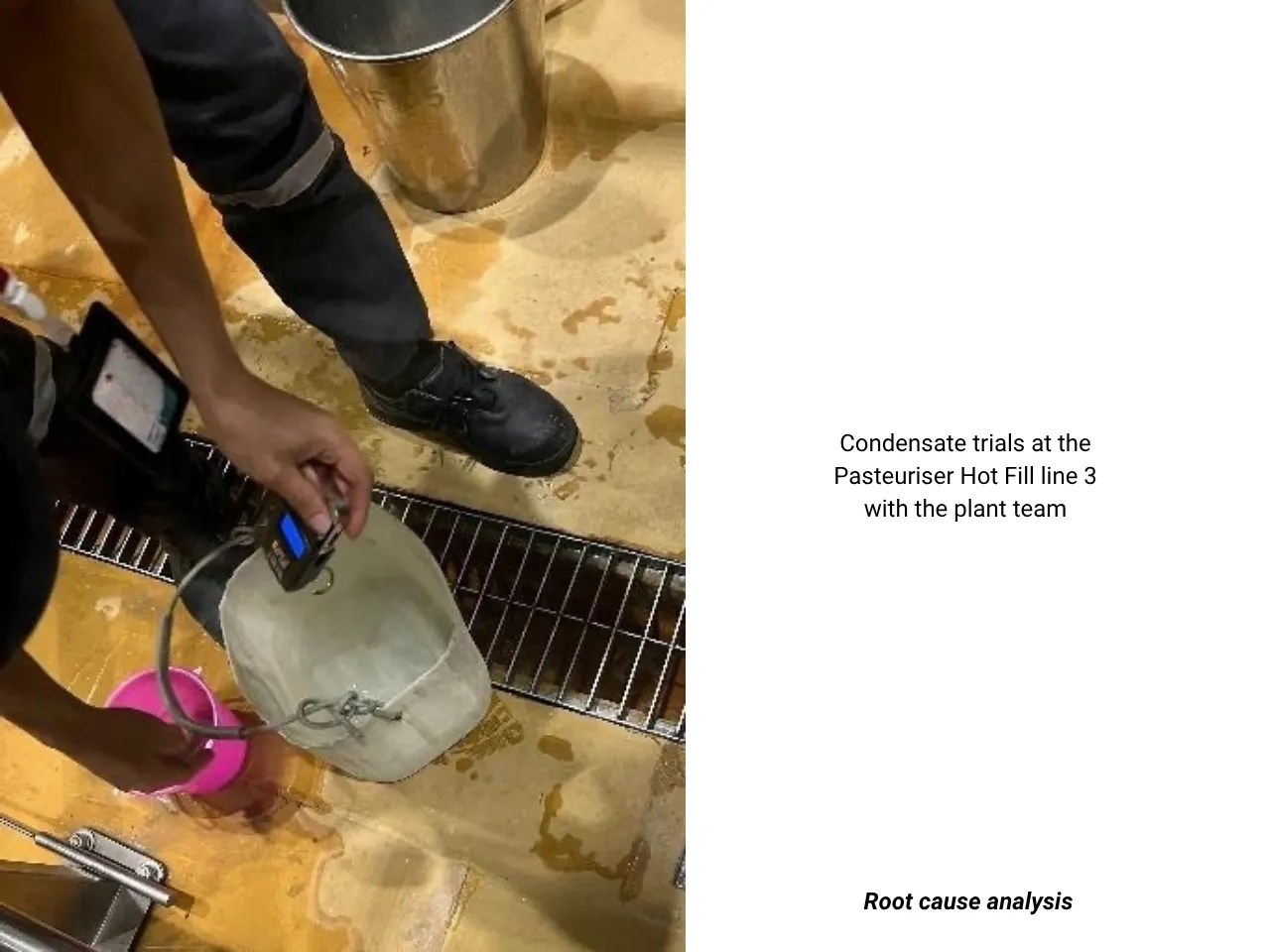

Forbes Marshall conducted trials at Pasteuriser Hot Fill line 3. The following solutions were recommended and implemented:

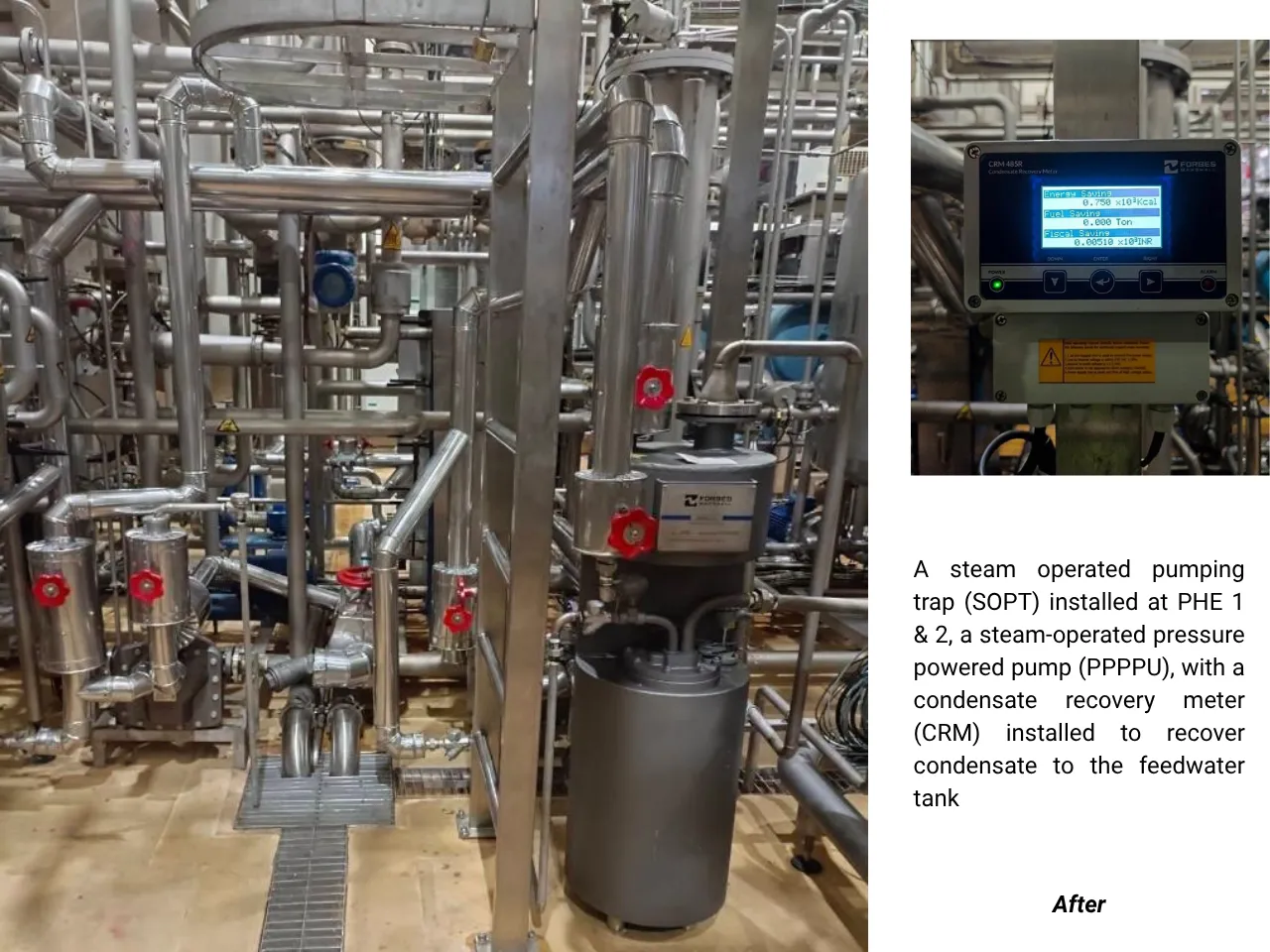

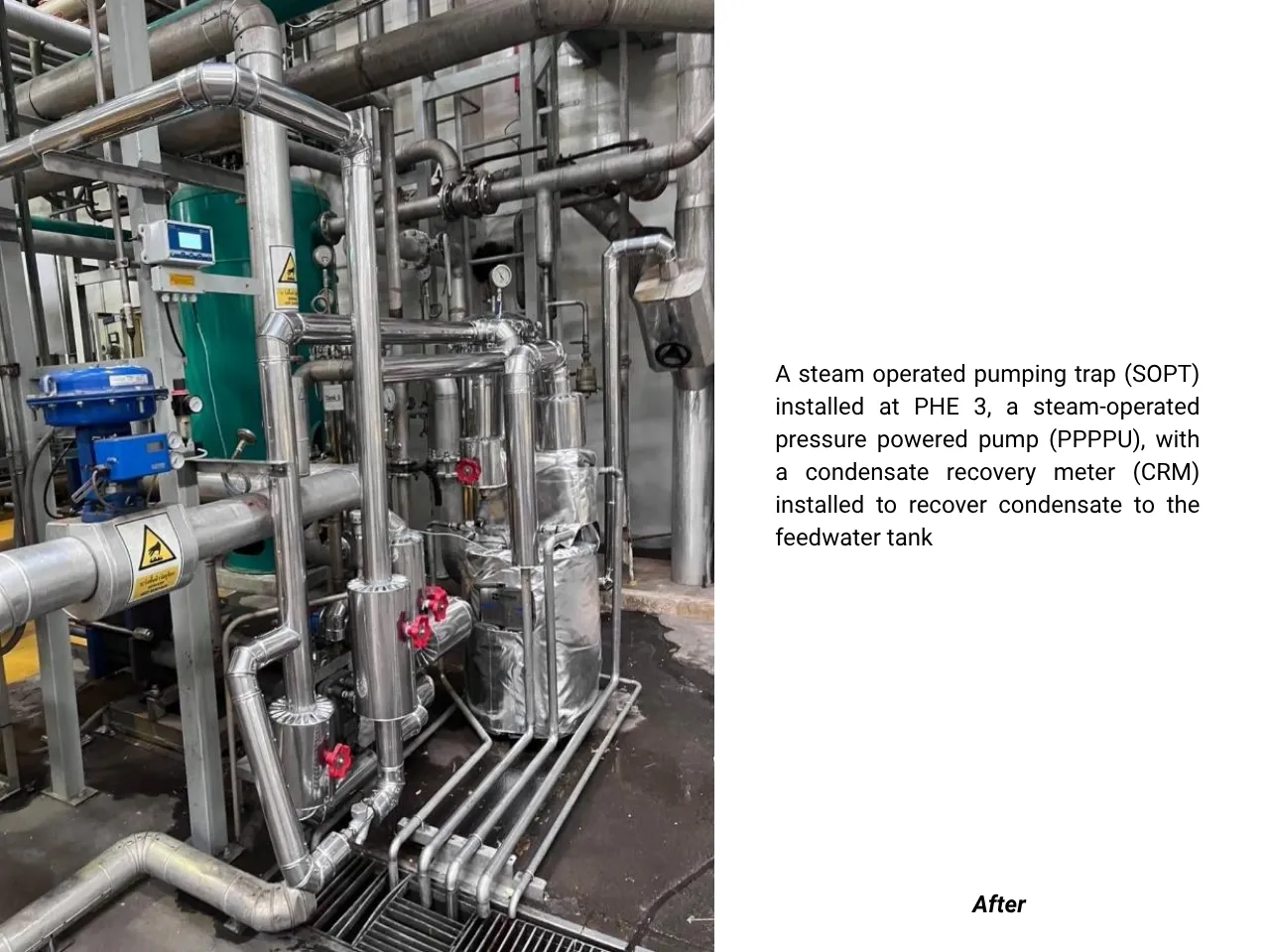

- 3 steam operated pumping traps (SOPT) at PHE 1, 2 & 3 were installed to address the issue of condensate logging seen when using a float trap

- 2 steam operated pressure powered pumps (PPPPU) with a condensate recovery meter (CRM) were installed to recover condensate to the feedwater tank

BENEFITS

207 Kilograms (59 Gallons) of furnace oil fuel saved daily

1,455 Tonnes (384K Gallons) of water saved annually

70 Tonnes (154K Pounds) of CO₂e reduced annually

Annual monetary savings of THB 439,521 (~USD 13,407 *converted based on exchange rate)

Products

Associated Services

Process Optimization

Improving Uptime

Forbes Marshal Digital

Associated Services

What to read next