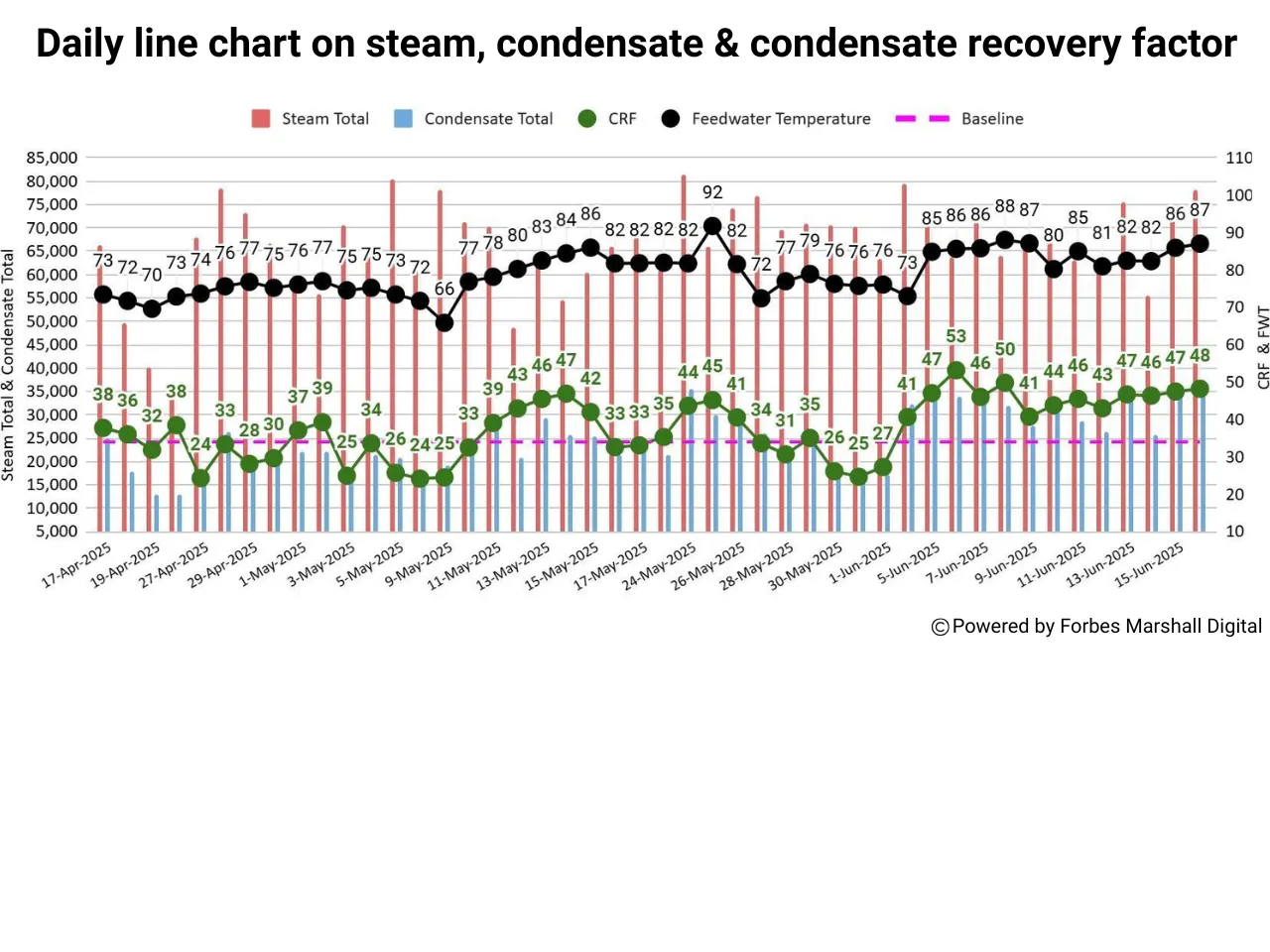

Improving CRF by 35.6% at a textile manufacturing plant, using EverSense for Condensate Recovery Factor

A textile manufacturer in North-West India faced variation in their utility KPIs impacting their productivity. Our partnership with FM Digital began in April 2025 with the shared goal of improving and sustaining key utility KPIs using EverSense for Condensate Recovery Factor (EverSense for CRF is a digital service designed to improve and sustain CRF across the plant). Parts of their steam system had leakages and there was overflow in the FlashJet Pump (FJP) due to low motive pressure supplied to the pump. Before the service started, CRF was ~37% while the feedwater temperature was ~71°C (i.e.~160°F).

Products

Associated Services

Process Optimization

Improving Uptime