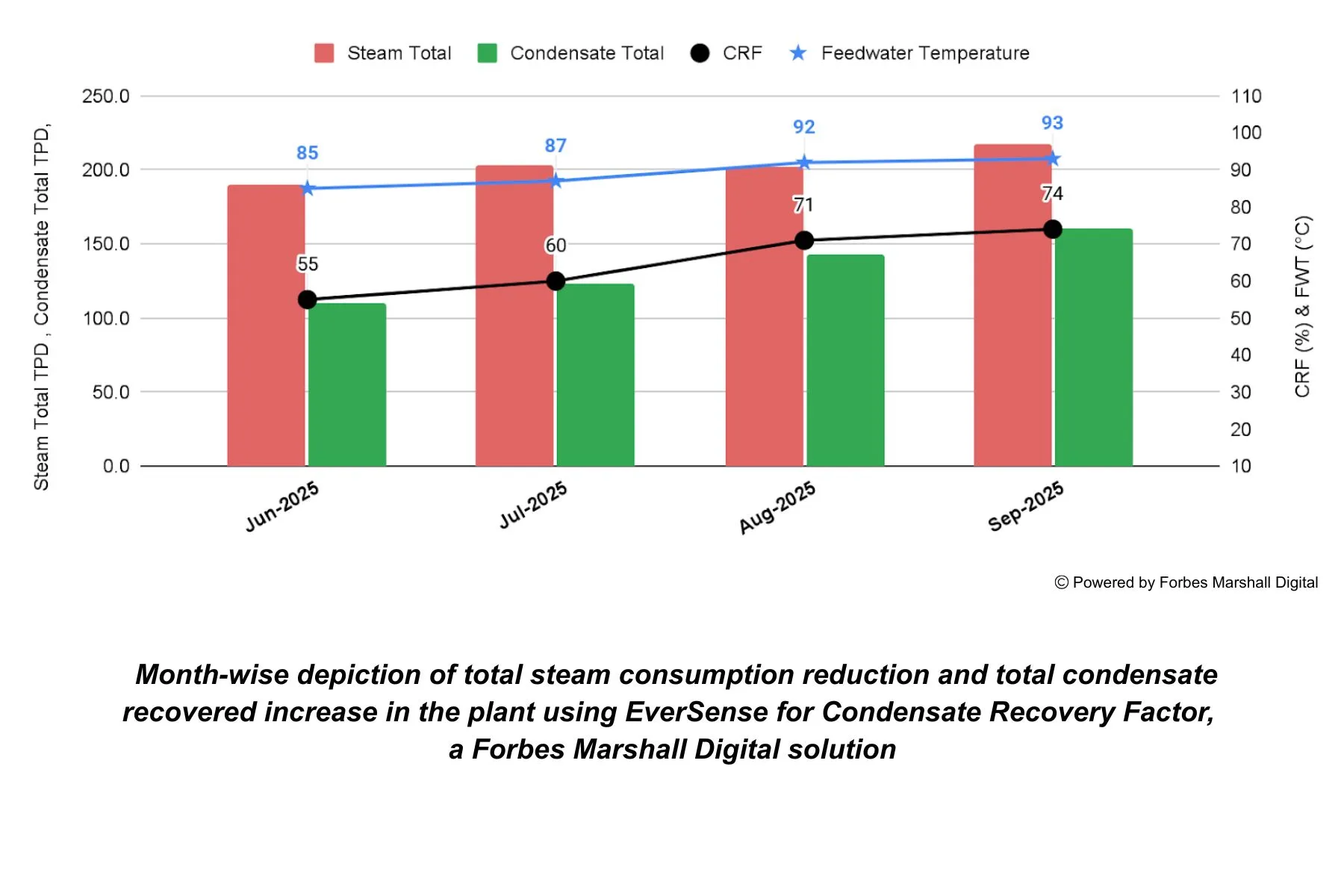

Earlier, the customer manually recorded data, including water consumption, which was relatively high, and fuel savings were low and difficult to establish.

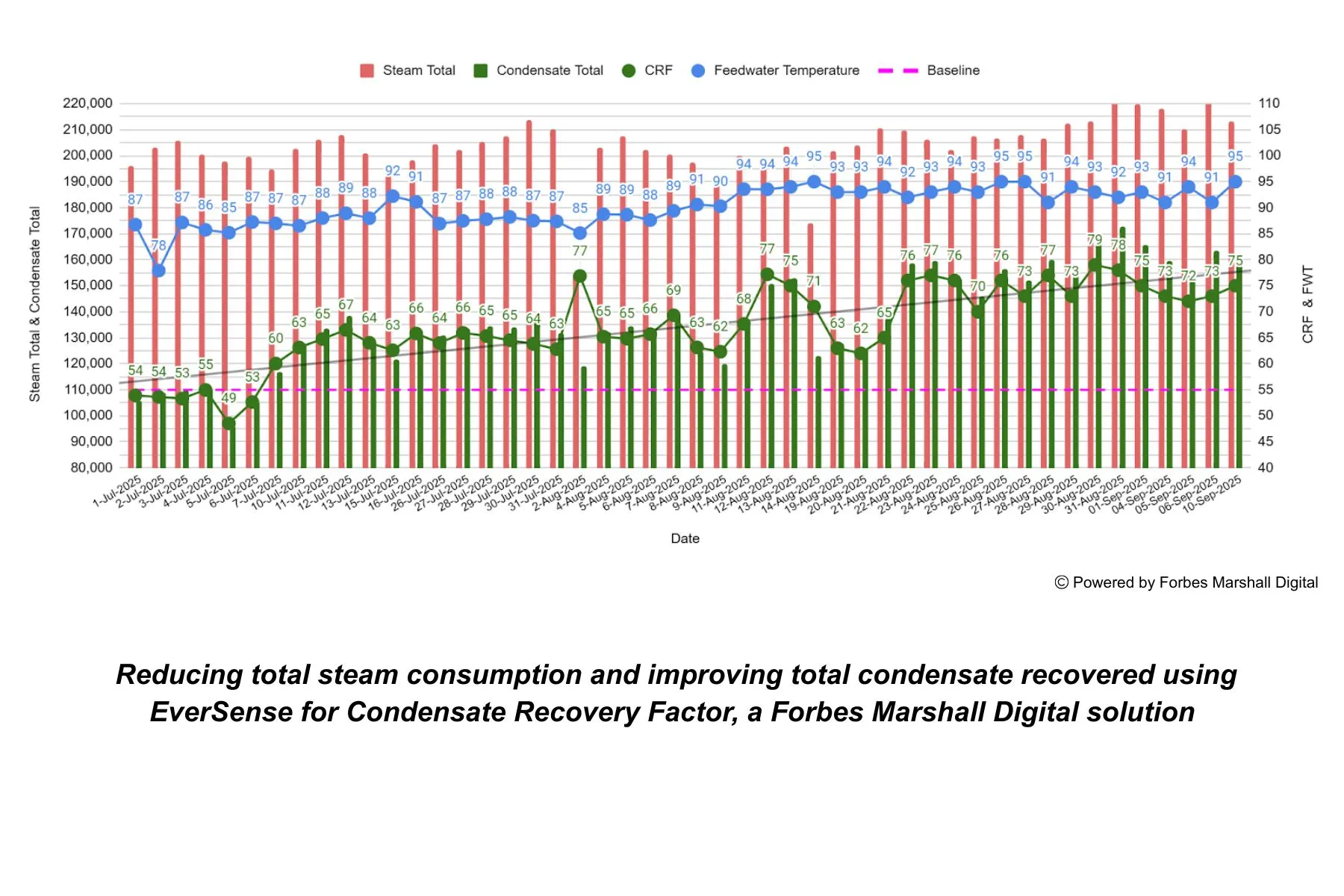

After the digital service was started for sustenance through EverSense for Condensate Recovery Factor, RTru was installed, parameters were added in the Condensate recovery meter, and Flow Indicator Totaliser data was collected through Modbus.

With proper configuration of FIT and CRM along with programming, data flow began with a live dashboard on EverSense, enabling sitewide updates by the minute, hour, and day. Additionally, daily basic reports highlighting observations and recommendations are shared by the Forbes Marshall team.

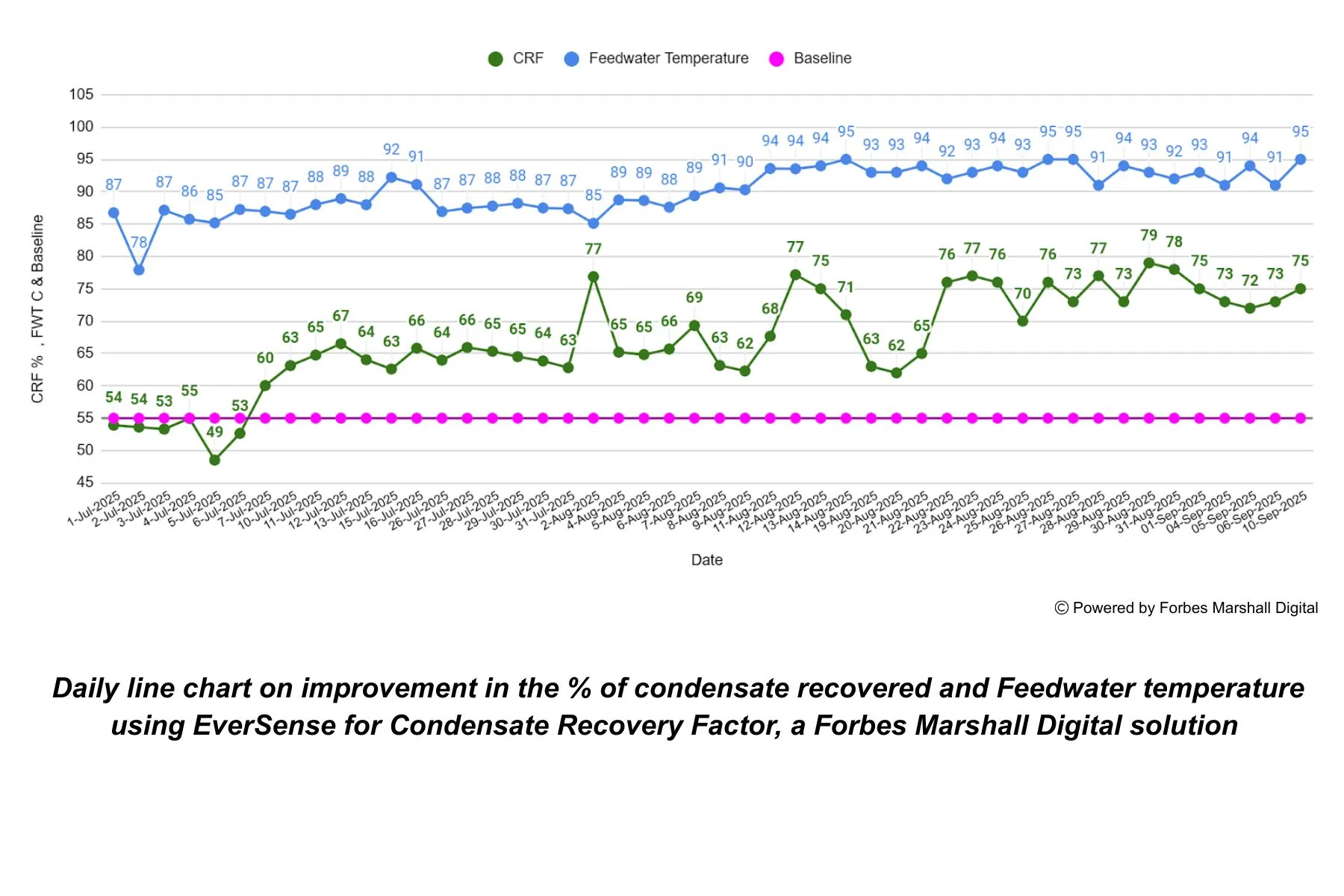

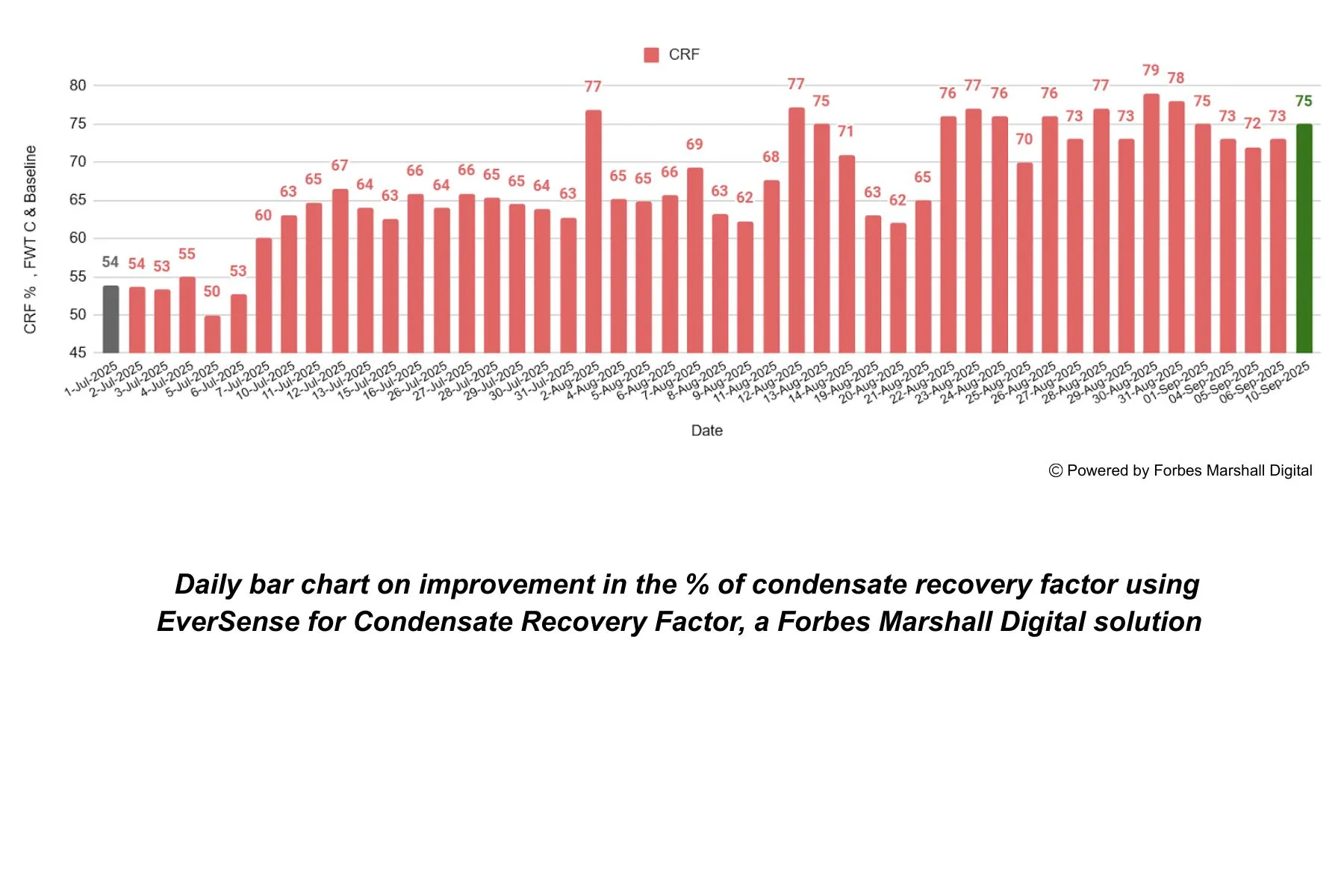

Daily parameters such as Condensate Recovery Factor (CRF), feedwater temperature, and pump data are monitored.

Key problems such as steam leakage and bypass steam were identified and fixed.

After the leakage was fixed, the FJP temperature improved from 60 to 83°C (140 to 181.4°F), indicating stable performance.

The equipment uptime was secured and machine-wise observations for the steam and condensate network was completed.

Historical data was collected for steam, condensate and fuel from the plant to establish a strong baseline.

In the MEE section, condensate pumps were not properly utilised. This was corrected, improving condensate recovery.

In the jet dyeing section, the bypass line was fully closed and steam traps were replaced to prevent losses.