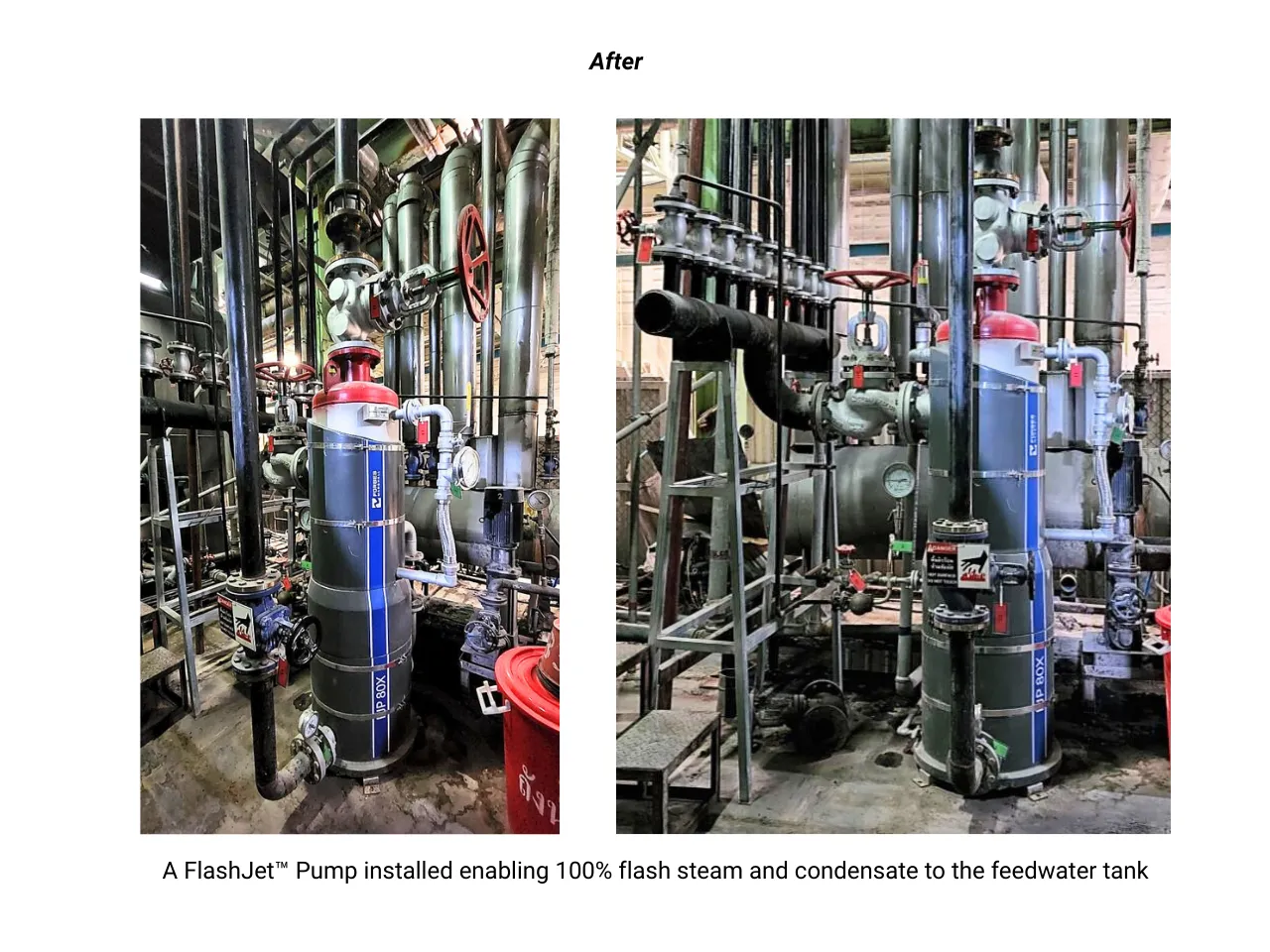

8.3% fuel saved annually through condensate recovery at a rice noodle and flour processor in Thailand

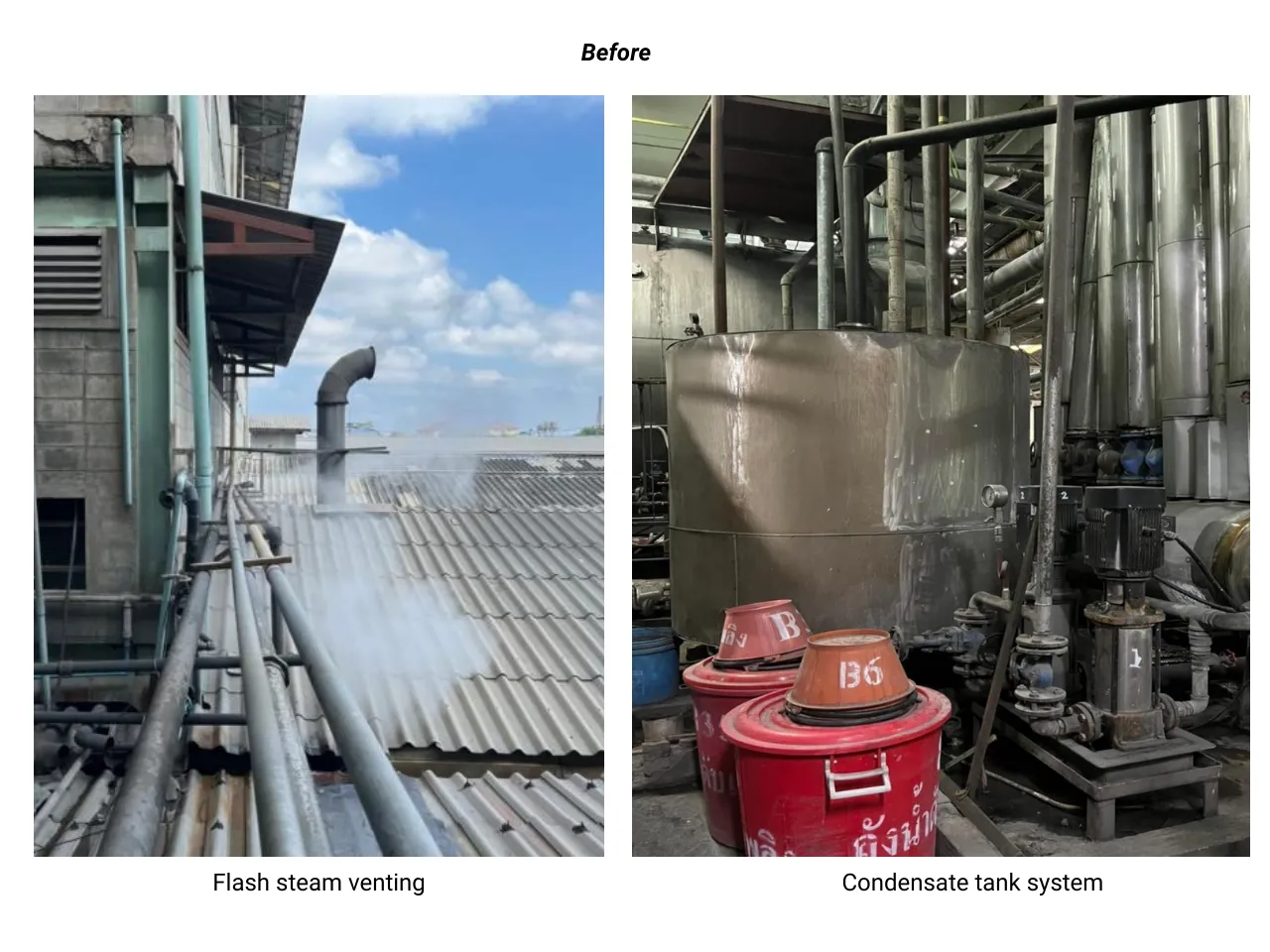

A rice noodle and flour processing plant in Nakhon Pathom, Thailand was not recovering condensate or flash steam due to an inoperational tank and electrical pump based conventional condensate recovery system. Forbes Marshall conducted a plant survey and recommended solutions to improve condensate recovery.

Products

Associated Services

Process Optimization

Improving Uptime