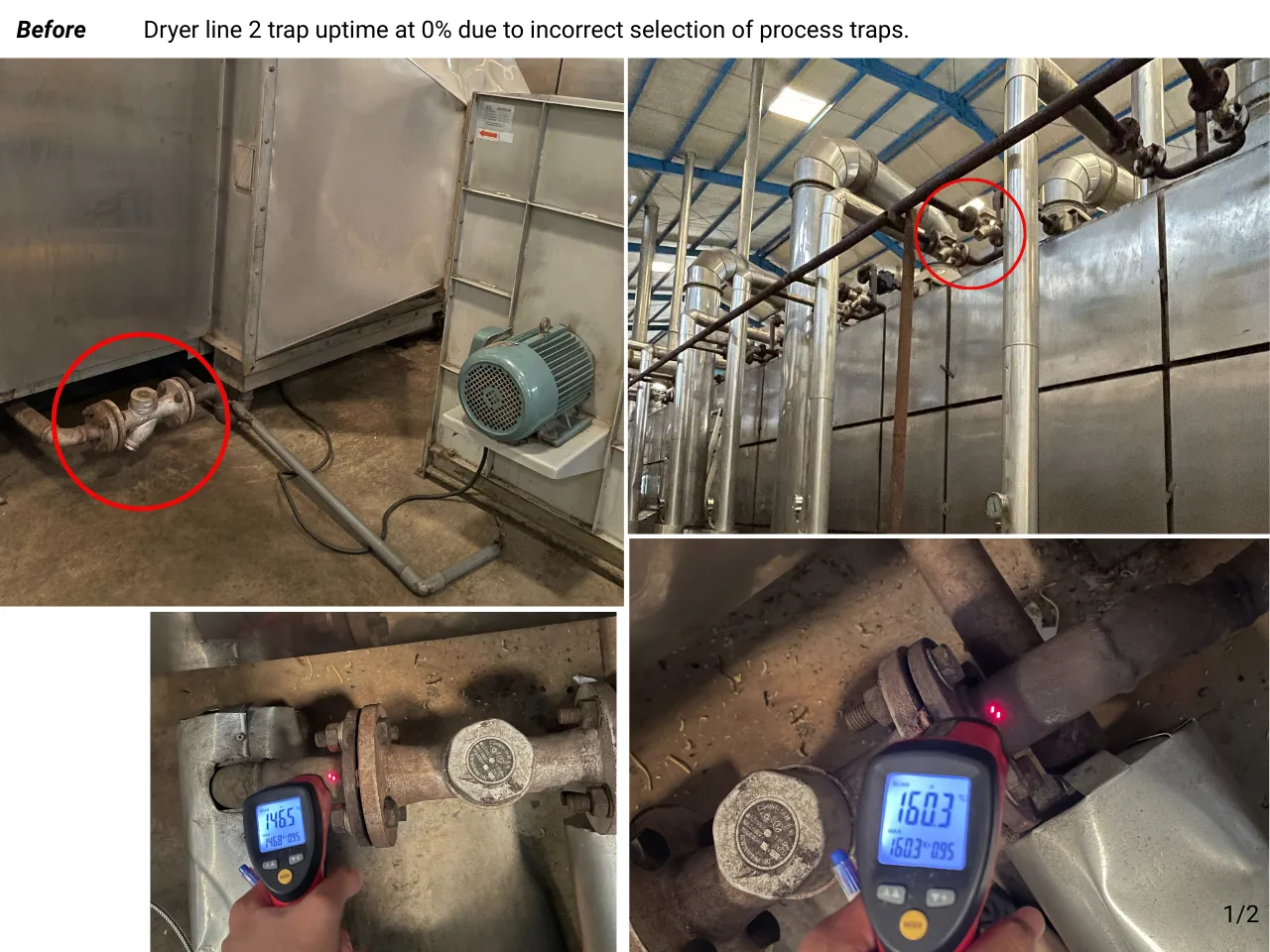

9% increase in production with 21.35% fuel saved through correct steam trap selection for a noodle plant in Indonesia

A noodle plant in East Jawa, Indonesia, was experiencing steam leakage in Dryer line 2, causing significant energy loss. Forbes Marshall implemented thermal energy conservation solutions to address the issues in the dryer line.

Products

Associated Services

Process Optimization

Improving Uptime