Increasing the condensate recovery by 40% for a textile manufacturer in India using FM Digital

A textile manufacturer in Lucknow, India was facing variation in their utility KPIs impacting their productivity. Parts of their steam and condensate recovery system had leakages. There were choking issues in the pump due to high total dissolved solids (TDS).

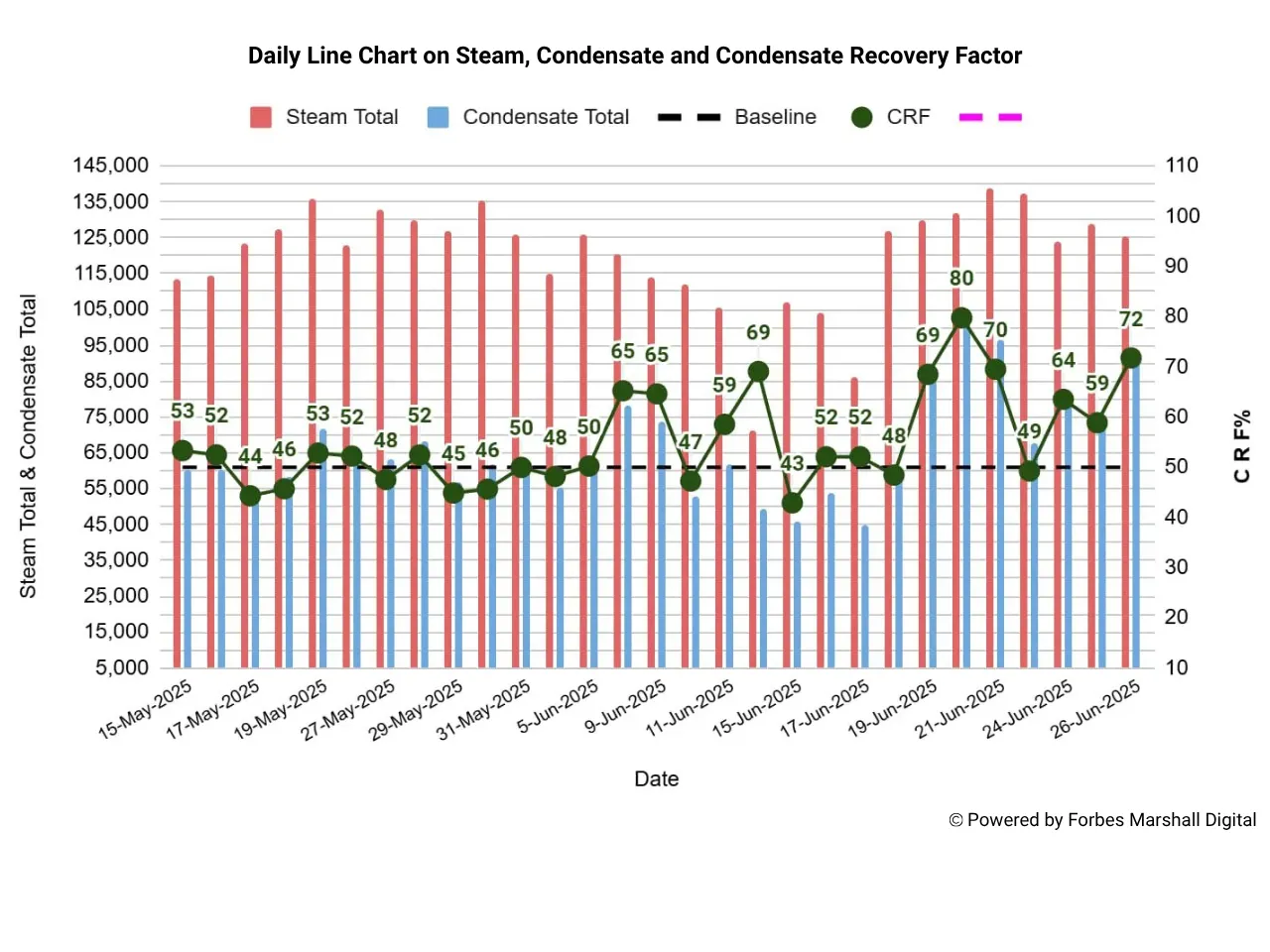

Their partnership with Forbes Marshall Digital started in April 2025 with a shared goal of improving and sustaining condensate recovery factor using EverSense for Condensate Recovery Factor.

Products

Associated Services

Process Optimization

Improving Uptime